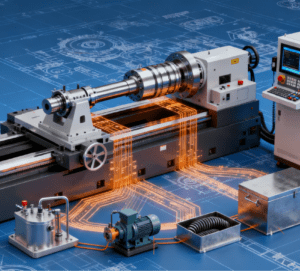

CNC (Computer Numerical Control) boring machining is a precision mechanical processing technology based on digital program control. Its core lies in inputting instructions through computer programming to drive the boring machine to complete operations such as hole machining, end face machining, chamfering, and complex curved surface machining of workpieces. As a digital upgraded version of traditional boring machining, it inherits the core principle of boring machines—”taking the rotation of the boring tool as the main movement and the movement of the workpiece or boring tool as the feed movement”—while integrating the precise control advantages of the CNC system, realizing automation, high precision, and high efficiency in the machining process.

Compared with traditional manual or ordinary mechanical boring machines, CNC boring machining does not require real-time manual control of the cutting process. The entire process from workpiece positioning to finished product output can be completed through a preset machining program. It is particularly suitable for the machining of high-precision hole systems, complex cavities, and large workpieces, and occupies an important position in fields such as machinery manufacturing, aerospace, and the automotive industry. Its core characteristics can be summarized in three points: first, digital control, where program instructions replace manual operations to reduce human errors; second, high-precision output, with machining accuracy reaching the micrometer level to meet the needs of precision parts; third, flexible production, where modifying the program can adapt to the machining of different workpieces, suitable for multi-variety and small-batch production scenarios.

Core Composition of CNC Boring Machining

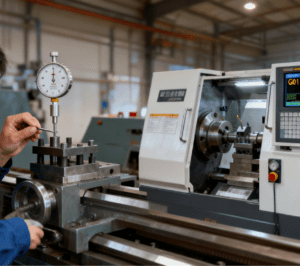

The CNC boring machining system consists of three major parts: mechanical structure, CNC system, and auxiliary devices. All components work together to ensure the stability and accuracy of the machining process:

Core Components of the Mechanical Structure

Machine Bed and Worktable: The machine bed is the basic support of the entire equipment, made of high-strength cast iron or welded structure, and must have sufficient rigidity and stability to avoid deformation during machining. The worktable is used to place workpieces, equipped with high-precision guide rails and clamping devices, enabling precise movement in the X and Y axis directions. Some high-end equipment supports multi-axis linkage to meet the spatial machining needs of complex workpieces.

Spindle Unit: As the cutting power source, the spindle is responsible for driving the rotation of the boring tool, and its accuracy directly affects the machining quality. The spindle is usually driven by a variable-frequency speed-regulating motor or a servo motor, supporting stepless speed change, and the speed can be adjusted according to the machining material (such as steel, aluminum, cast iron) and process requirements. At the same time, it is equipped with high-precision bearings and a cooling system to reduce vibration and heat generation during high-speed rotation and ensure cutting stability.

Feed Transmission System: Composed of servo motors, ball screws, guide rails, etc., it is responsible for controlling the feed movement of the worktable or spindle. The cooperation between the ball screw and the servo motor enables precise control of the feed rate, while the guide rails ensure the smoothness of movement and positioning accuracy, avoiding crawling phenomena and ensuring the consistency of machining dimensions.

Boring Tool System: Including boring tool holders, boring tool heads, and tool clamping devices. Different types of boring tools (such as through-hole boring tools, blind-hole boring tools, and fine-adjustment boring tools) can be selected according to machining needs. The tool materials are mostly cemented carbide, high-speed steel, or diamond coatings, which must have high strength and high wear resistance to adapt to the cutting needs of different materials.

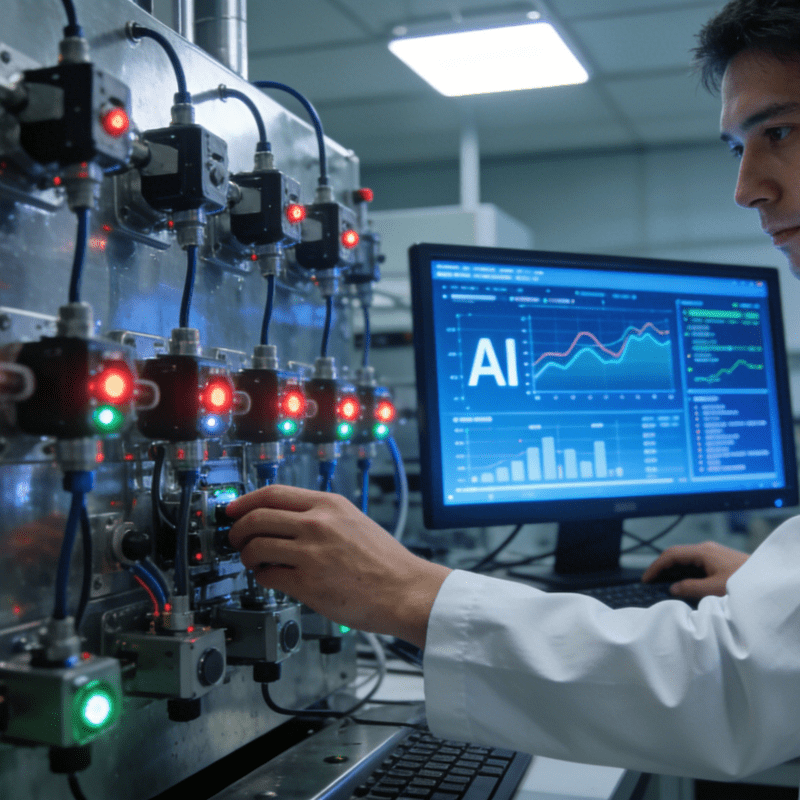

CNC System (Core Control Unit)

The CNC system is the “brain” of the CNC boring machine, composed of hardware (controller, display, operation panel, servo driver) and software (operating system, programming software, machining simulation software). Its core functions include:

Program Input and Editing: Supports manual programming (G-code, M-code) or automatic program generation by CAD/CAM software, which can be imported into the equipment via USB flash drive, network, or other methods.

Motion Control: Parses program instructions, drives the coordinated movement of the spindle and feed system, and realizes multi-axis linkage control.

Precision Compensation: Equipped with tool length compensation, radius compensation, and machine tool error compensation functions to correct errors during the machining process.

Status Monitoring: Real-time display of machining progress, tool wear status, and equipment operation status, with automatic alarm in case of abnormalities to ensure machining safety.

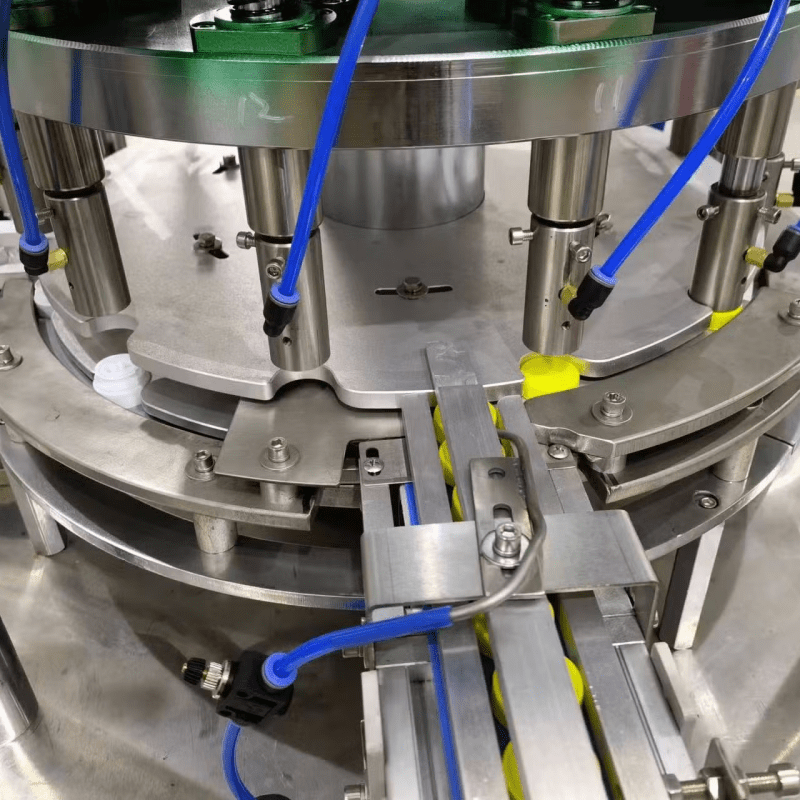

Auxiliary Devices

Cooling and Lubrication System: Through the cyclic injection of cutting fluid, it reduces the cutting temperature, reduces tool wear, and flushes away chips at the same time to avoid chip residues affecting machining accuracy.

Chip Removal Device: Timely discharges chips generated during machining, suitable for mass machining scenarios and keeps the worktable clean.

Protective Device: Adopts a closed or semi-closed structure to prevent cutting fluid splashing and chips from harming people, while reducing the impact of external dust on the equipment.

Detection Device: Some high-end equipment is equipped with on-line measurement systems (such as laser probes, contact probes) to detect workpiece dimensions in real time, automatically feed back and correct machining parameters, and further improve machining accuracy.

Core Functions of CNC Boring Machining

The core value of CNC boring machining lies in meeting the needs of precision machining, complex machining, and high-efficiency machining, and its functions are mainly reflected in the following four aspects:

Core Solution for High-Precision Hole System Machining

Hole machining is a traditional advantage field of boring machines, and CNC boring machines have achieved a leap in precision on this basis. They can machine holes with diameters ranging from a few millimeters to hundreds of millimeters, and are particularly suitable for machining complex hole systems such as deep holes, stepped holes, and eccentric holes. The hole diameter tolerance can be controlled within ±0.005mm, and the roundness, cylindricity, and hole spacing accuracy of the holes can all meet the requirements of precision mechanical parts. In key components such as engine cylinder blocks, gearbox housings, and machine tool spindle boxes, the machining accuracy of the core hole system directly affects the operating efficiency and service life of the equipment. Therefore, CNC boring machining has become an essential process for the production of such components.

Flexible Machining of Complex Curved Surfaces and Cavities

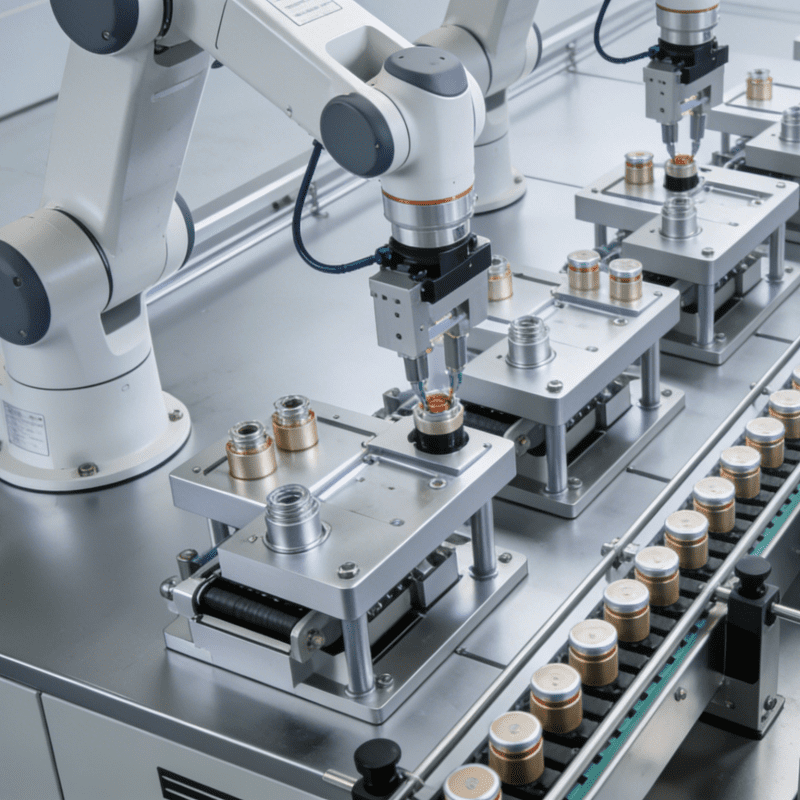

With the increasing demand for part structure complexity in the manufacturing industry, traditional machining processes can hardly meet the machining needs of complex curved surfaces and special-shaped cavities. Through multi-axis linkage (such as 3-axis, 4-axis, and 5-axis linkage), CNC boring machines can realize continuous cutting of spatial curved surfaces and irregular cavities without multiple clamping, reducing clamping errors. For example, engine blades in the aerospace field, mold cavities in the machinery field, and complex parts in the automotive field all rely on CNC boring machining to achieve precise forming of complex structures.

Multi-Process Integration to Improve Production Efficiency

CNC boring machines can integrate multiple machining processes such as boring, milling, drilling, reaming, and tapping. A workpiece can be machined on multiple sides and through multiple processes with a single clamping, eliminating the need to transfer the workpiece between different equipment, which greatly reduces clamping time and transportation costs. This integrated machining mode not only improves production efficiency but also avoids positioning errors caused by multiple clamping, ensuring the dimensional consistency between processes. For multi-variety and small-batch production scenarios, CNC boring machines can adapt to the machining of different workpieces by quickly modifying the machining program, which reduces the process adjustment time compared with traditional equipment and demonstrates significant flexible production advantages.

Supporting Stable Production in High-End Manufacturing

In fields with extremely high requirements for part quality, such as aerospace, national defense and military industry, high-end equipment manufacturing, and medical device production, the stability and reliability of CNC boring machining are crucial. It can realize the consistency control of parts in mass production, avoid quality fluctuations caused by human factors, and at the same time reduce the assembly error of parts through high-precision machining, improving the performance of the entire equipment. For instance, key components of aero-engines, core parts of precision instruments, and critical structural components of biological indicator assembly machines—such as sealed cavities and precision positioning holes—all rely on CNC boring machining to meet strict dimensional and sealing requirements. The micrometer-level precision of CNC boring ensures the biological indicator assembly machine can achieve accurate assembly of culture media tubes, sealing gaskets, and detection sensors, maintaining the reliability of sterilization verification results in medical and pharmaceutical scenarios. As such, CNC boring machining has become an indispensable technical support for the high-quality production of medical precision equipment like biological indicator assembly machines, empowering the standardized development of the medical and pharmaceutical industry.

As one of the core technologies in precision mechanical processing, CNC boring machining has become an indispensable processing method in modern manufacturing due to its characteristics of digital control, high-precision output, and flexible production. From the perspective of core composition, the rigidity of the mechanical structure, the intelligence of the CNC system, and the adaptability of auxiliary devices jointly determine the machining quality and efficiency. From the perspective of practical functions, it not only solves the machining problems of precision hole systems and complex structures but also improves production efficiency through multi-process integration, providing technical support for the high-quality development of various industries. With the continuous advancement of intelligent manufacturing technology, CNC boring machining will develop towards higher precision, higher efficiency, and greater intelligence, continuously empowering the transformation and upgrading of the manufacturing industry.

What is the market price of a continuous motion multi-piece special-shaped machine?