CNC bending technology is mainly realized by CNC bending machines. A CNC bending machine consists of two major components: the mechanical structure and the CNC system. The mechanical structure includes parts such as the worktable, slider, and mold. Its working principle is that the CNC system precisely controls the movement trajectory and pressure of the slider, causing the metal sheet placed on the worktable to undergo plastic deformation under the action of the mold, thereby achieving the bending operation.

The CNC system is the core of CNC bending technology. First, the operator inputs relevant bending parameters, such as bending angle, bending length, and bending speed, into the CNC system. Based on these parameters, the CNC system calculates the movement trajectory and required pressure of the slider, and accurately controls the hydraulic or electric system to drive the slider’s movement. During the bending process, the CNC system can also monitor and adjust the position and pressure of the slider in real time to ensure bending precision.

Advantages of CNC Bending Technology

High Precision

CNC bending technology can achieve extremely high bending precision. Traditional manual bending makes it difficult to precisely control the bending angle and length, while CNC bending machines can control the bending precision within a very narrow range, usually reaching an accuracy of ±0.1° or even higher. This is crucial for products with stringent precision requirements, such as precision instrument casings and aerospace components.

High Repeatability

Since the CNC system operates strictly according to preset programs, the result of each bending operation is highly repeatable. This feature ensures that the bent parts of all products remain highly consistent during mass production, guaranteeing product quality stability.

Flexibility

CNC bending machines can adapt to different bending tasks by simply modifying the CNC program. Whether for sheets of different shapes and sizes or different bending requirements, all operations can be completed on the same CNC bending machine without the need for frequent mold or equipment replacement.

Applications of CNC Bending Technology

Mechanical Manufacturing

In mechanical manufacturing, many components require bending operations, such as chassis, cabinets, and brackets. CNC bending technology can ensure the bending precision of these components, improving the assembly precision and quality of the entire mechanical product. Moreover, many of these bent components need to be equipped with circlips for structural fixation, and the introduction of an Automatic Circlip Feeding System has further optimized the production process—it can automatically and precisely deliver circlips to the assembly position of the bent parts, avoiding assembly errors caused by manual feeding and matching the high precision of CNC bending, thus greatly improving the overall assembly efficiency and product consistency.

Architectural Decoration

The architectural decoration field often uses metal sheets for shaping and decoration. CNC bending technology can bend metal sheets into various complex shapes, such as arcs and waves, meeting the requirements of architectural decoration for aesthetic and unique designs.

Electrical Appliance Manufacturing

The casings of electrical products usually require bending processing. CNC bending technology can ensure the bending precision of the casings, making their assembly more tight, while also meeting the appearance quality requirements of electrical products.

Development Trends of CNC Bending Technology

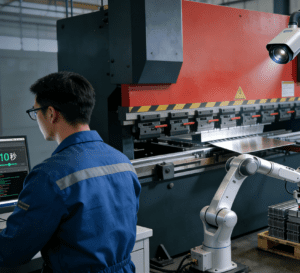

Intelligentization

With the development of artificial intelligence technology, CNC bending machines will move towards intelligentization. Future CNC bending machines may be equipped with functions such as automatic programming, intelligent fault diagnosis, and adaptive bending, further improving production efficiency and bending quality.

Multi-functionality

To meet more diversified production needs, CNC bending machines will continue to add new functions. For example, they may have the capability to perform different bending methods simultaneously, or integrate other metal processing functions to become multi-functional metal processing equipment.

In conclusion, CNC bending technology plays an irreplaceable role in the metal processing field with its advantages of high precision, high repeatability, and flexibility.