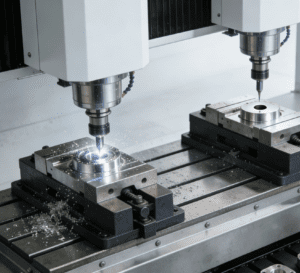

With the rapid development of science and technology, traditional machining methods are gradually struggling to meet increasingly complex production demands, while CNC 4-axis machining stands out with its outstanding advantages. It is not merely a machining technology, but also a powerful driving force propelling the continuous advancement of various industries. So, what are the remarkable advantages of CNC 4-axis machining?

The advantages of CNC 4-axis machining are mainly reflected in the following five aspects:

High-Precision Machining

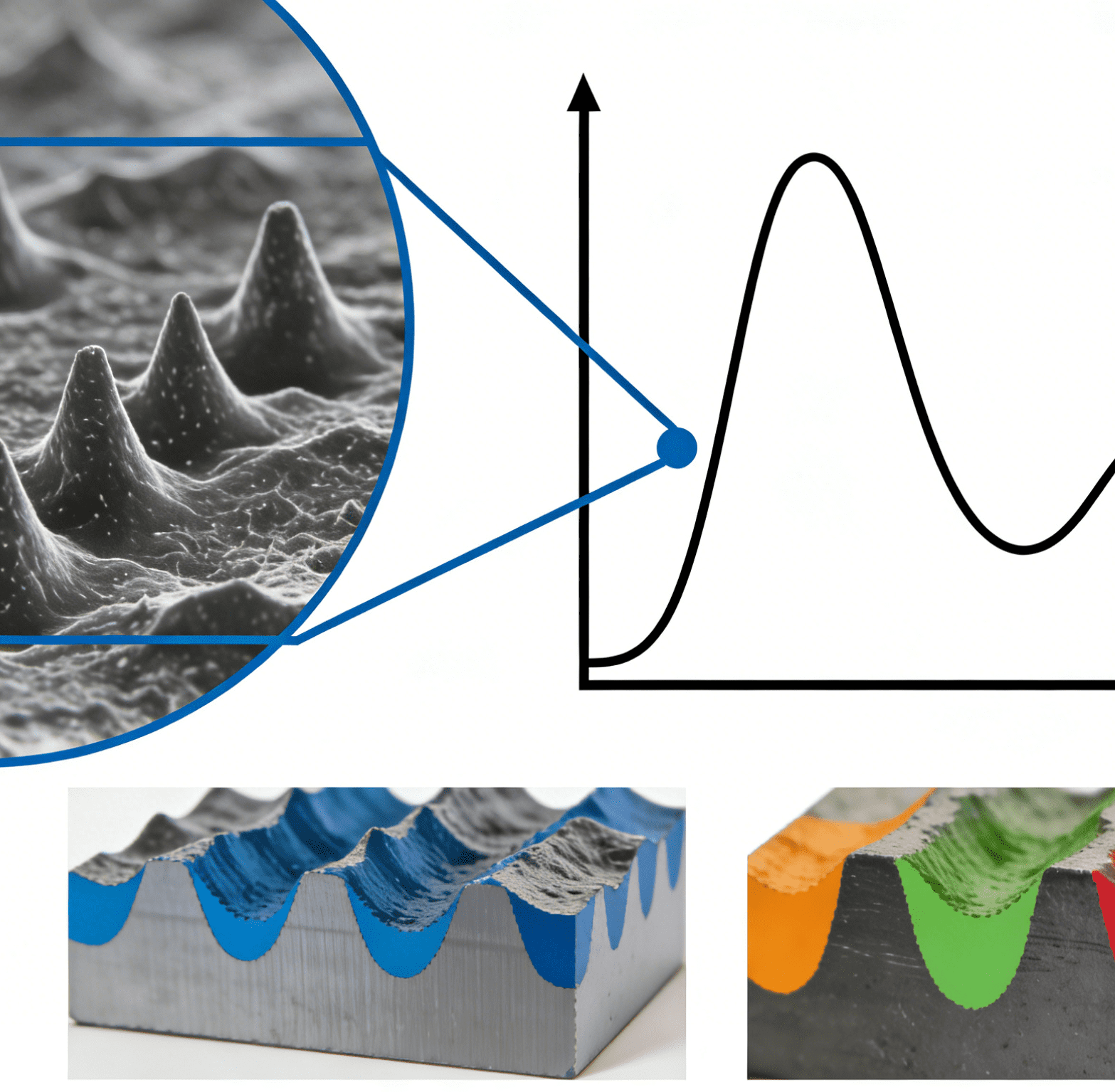

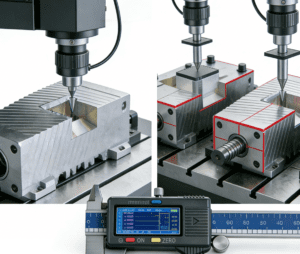

CNC 4-axis machining can achieve extremely high machining precision. In traditional 3-axis machining, due to limitations imposed by workpiece shapes and machining requirements, multiple clamping and adjustment procedures may be required, which tend to introduce errors. By adding an extra rotary axis, 4-axis machining enables the completion of more machining processes in a single clamping, thus greatly reducing errors caused by repeated clamping. Meanwhile, advanced control systems and precision mechanical structures ensure the movement accuracy of cutting tools during machining, resulting in components with more accurate dimensions and superior surface quality.

Strong Machining Flexibility

The rotary axis of 4-axis machining endows the machining process with great flexibility. For components with complex curved surfaces, inclined angles, or helical structures, traditional 3-axis machining is often incompetent. In contrast, 4-axis machining can adjust the rotary axis to allow cutting tools to access the workpiece from different angles, easily realizing the machining of these complex shapes. Whether it is high-precision components in the fields of automotive parts, aerospace components, or medical devices, 4-axis machining can meet their diversified machining requirements.

Improved Production Efficiency

On one hand, the characteristic of multi-process machining in one clamping of 4-axis machining reduces auxiliary time during the machining process, avoiding frequent clamping and adjustments, thereby significantly improving production efficiency. On the other hand, the multi-axis linkage machining method enables high-speed cutting, accelerating the machining speed. At the same time, advanced programming technologies and automated control systems can optimize machining paths, further enhancing machining efficiency and reducing production costs.

Expanded Machining Scope

CNC 4-axis machining can not only process conventional components, but also expand into some special fields. For example, in the fields of artistic sculpture and ornament manufacturing, 4-axis machining can produce exquisite curved surface shapes and complex patterns, providing new methods for artistic creation. In the mold manufacturing industry, 4-axis machining can fabricate more complex and precise molds, improving mold quality and service life, thus offering better guarantees for product production. Notably, in the electronic manufacturing industry, it plays a critical role in processing core components of Automatic Placement Machines—such as precision suction nozzles, multi-angle positioning brackets, and micro-motion transmission shafts. These components require micron-level precision for inclined channels, curved contact surfaces, and helical tooth structures to ensure the stable placement of tiny electronic components (like 01005-sized chips). 4-axis machining’s single-clamping multi-angle processing capability realizes efficient and accurate fabrication of these complex structures, directly supporting the high-speed and high-precision operation of Automatic Placement Machines in SMT production lines.

Adaptability to Complex Machining Tasks

In some fields with extremely high requirements for machining precision and surface quality, such as aerospace and medical devices, CNC 4-axis machining can excellently complete complex machining tasks. For instance, the machining of aero-engine blades requires high-precision curved surface machining and strict dimensional control. 4-axis machining can realize efficient machining of the complex shapes of blades through precise programming and control, ensuring the performance and safety of the engine.