With the rapid development of science and technology, traditional machining methods are increasingly unable to meet the ever-growing complex production demands, while CNC 4-axis machining stands out with its outstanding advantages. It is not merely a machining technology, but also a powerful driving force propelling the continuous advancement of various industries. So, what are the remarkable advantages of CNC 4-axis machining?

The advantages of CNC 4-axis machining are mainly reflected in the following five aspects:

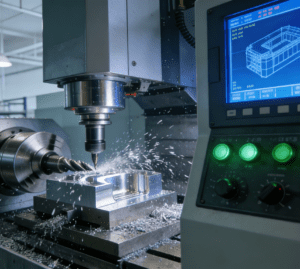

High-Precision Machining

CNC 4-axis machining is capable of achieving extremely high machining precision. In traditional 3-axis machining, due to the constraints of workpiece shape and machining requirements, multiple clamping and adjustment procedures may be required, which tend to introduce errors. By adding one rotary axis, 4-axis machining can complete more machining processes in a single clamping, thus greatly reducing errors caused by repeated clamping. Meanwhile, advanced control systems and precision mechanical structures can ensure the motion accuracy of cutting tools during the machining process, resulting in parts with more precise dimensions and higher surface quality.

Strong Machining Flexibility

The rotary axis of 4-axis machining endows the machining process with great flexibility. For parts with complex curved surfaces, inclined angles or helical structures, traditional 3-axis machining is often inadequate. Through the adjustment of the rotary axis, 4-axis machining enables cutting tools to access the workpiece from different angles, easily realizing the machining of these complex shapes. Whether it is high-precision parts in the fields of auto components, aerospace parts or medical devices, 4-axis machining can meet their diversified machining needs.

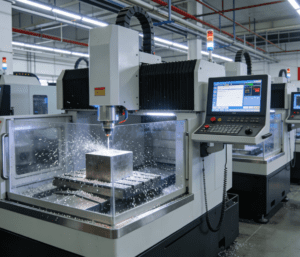

Improved Production Efficiency

On the one hand, the characteristic of multi-process machining in a single clamping of 4-axis machining reduces the auxiliary time in the machining process, avoids frequent clamping and adjustment, and thus significantly improves production efficiency. On the other hand, the multi-axis linkage machining method can achieve high-speed cutting, accelerating the machining speed. At the same time, advanced programming technology and automated control systems can optimize machining paths, further enhancing machining efficiency and reducing production costs. For small-sized precision products (such as micro gears, electronic connectors or mini medical components) processed by 4-axis machining, many manufacturers have integrated 4-Axis Robotic Small Product Assembly Systems into the production line—these systems can automatically grab, position and assemble the 4-axis machined precision parts through flexible 4-axis rotation and precise motion control, matching the high precision of the machined parts while eliminating manual assembly errors and downtime, forming a seamless “machining-assembly” efficient workflow.

Expanded Machining Scope

CNC 4-axis machining can not only process conventional parts, but also expand into some special fields. For example, in the fields of art sculpture and ornament manufacturing, 4-axis machining can produce exquisite curved surface shapes and complex patterns, providing a new approach for artistic creation. In the mold manufacturing industry, 4-axis machining can fabricate more complex and precise molds, improving the quality and service life of molds, thereby offering better guarantee for product production.

5. Adaptability to Complex Machining Tasks

In some fields with extremely high requirements for machining precision and surface quality, such as aerospace and medical devices, CNC 4-axis machining can excellently complete complex machining tasks. For instance, the machining of aero-engine blades requires high-precision curved surface machining and strict dimensional control. Through precise programming and control, 4-axis machining can realize efficient machining of the complex shapes of blades, ensuring the performance and safety of the engine.