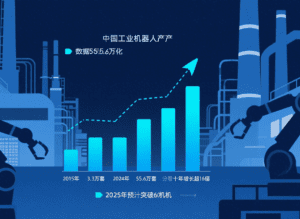

Guide: It is worth being proud! China has remained the world’s largest industrial robot market for 12 consecutive years! The output of China’s industrial robots has jumped from 33,000 units in 2015 to 556,000 units in 2024, an increase of more than 16 times in ten years, and is expected to exceed 600,000 units in 2025.

The latest news shows that since 2015, China has maintained its position as the world’s largest industrial robot market for 12 consecutive years.

The output of China’s industrial robots surged from 33,000 units in 2015 to 556,000 units in 2024, a more than 16-fold increase over ten years, and is projected to exceed 600,000 units in 2025. In 2024, sales in China’s industrial robot market exceeded 302,000 units, more than 4 times the 70,000 units sold in 2015. In terms of exports, the growth rate of industrial robot exports in the first half of 2025 reached 61.5%, with the European market accounting for nearly 30% of the share.

This achievement not only demonstrates China’s strong strength and market demand in the field of industrial robots but also indicates the determination and pace of China’s manufacturing industry in transforming towards intelligence and automation.

In terms of application scenarios, industrial robots have been widely used in 71 major industry categories and 236 medium industry categories of the national economy.

It is worth noting that in the manufacturing sector, the robot density in the automotive, electronics, photovoltaic, and lithium battery industries is particularly prominent, helping China’s manufacturing industry climb to the third place in the world in terms of robot density.

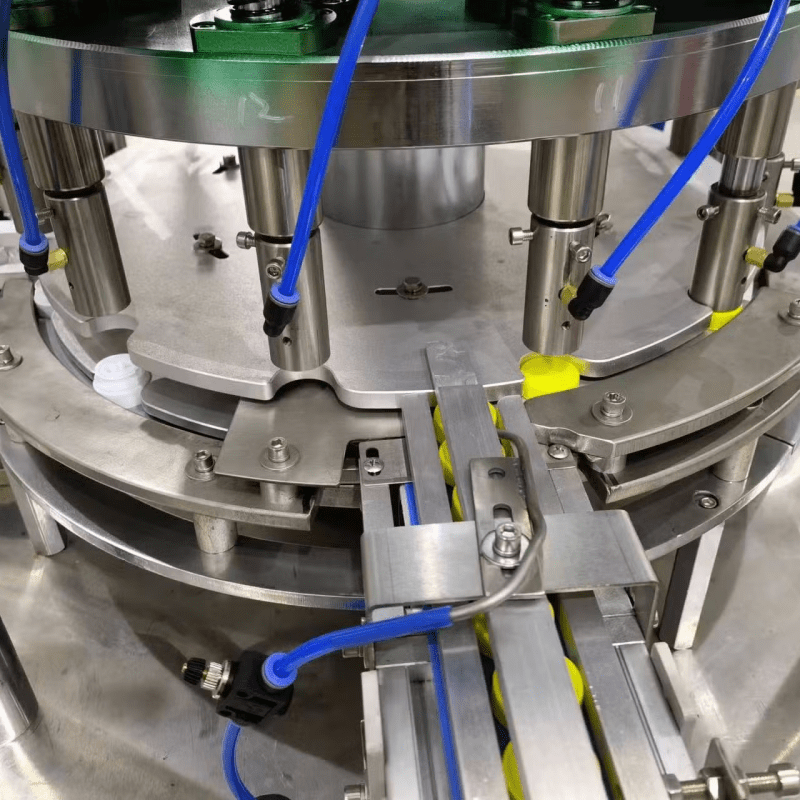

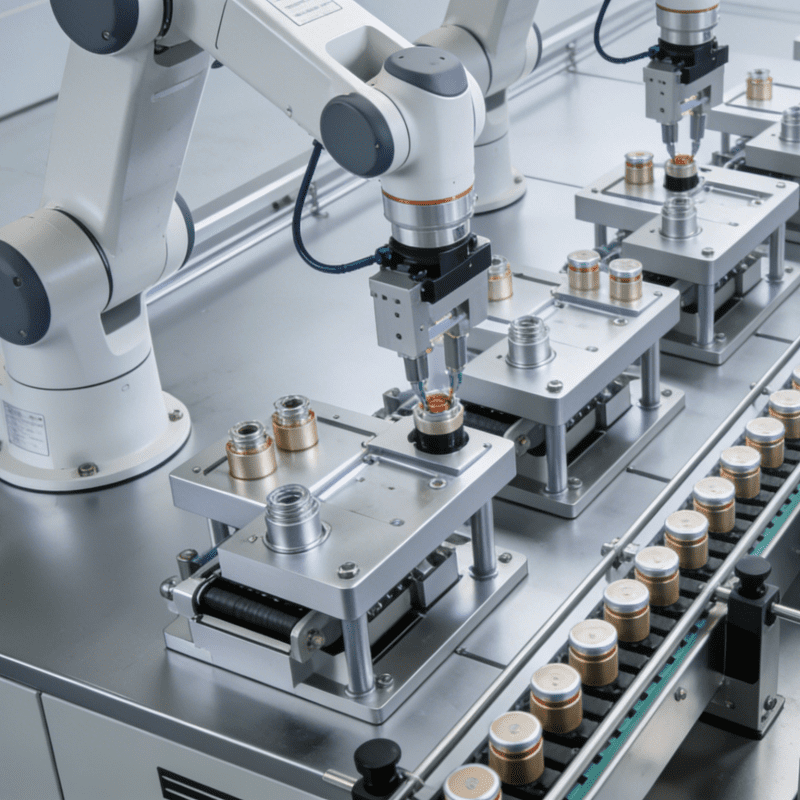

Among these, the automotive industry has performed exceptionally well. With the booming development of the electric vehicle market and the transformation of traditional automobile manufacturing to intelligent manufacturing, robots are increasingly being used in automobile production lines. Robots are involved in every link, from welding and assembly to quality inspection.

The electronics industry relies on high-precision and high-efficiency robots for precision operations such as chip packaging and circuit board assembly, which has significantly improved production efficiency and product quality.

The photovoltaic industry has extensively applied robots in processes such as silicon wafer cutting and battery module assembly, which not only reduces labor costs but also improves production safety.

In the lithium battery industry, robots also play an irreplaceable role in key processes such as cell winding, liquid injection, and packaging, promoting the development of the new energy industry.

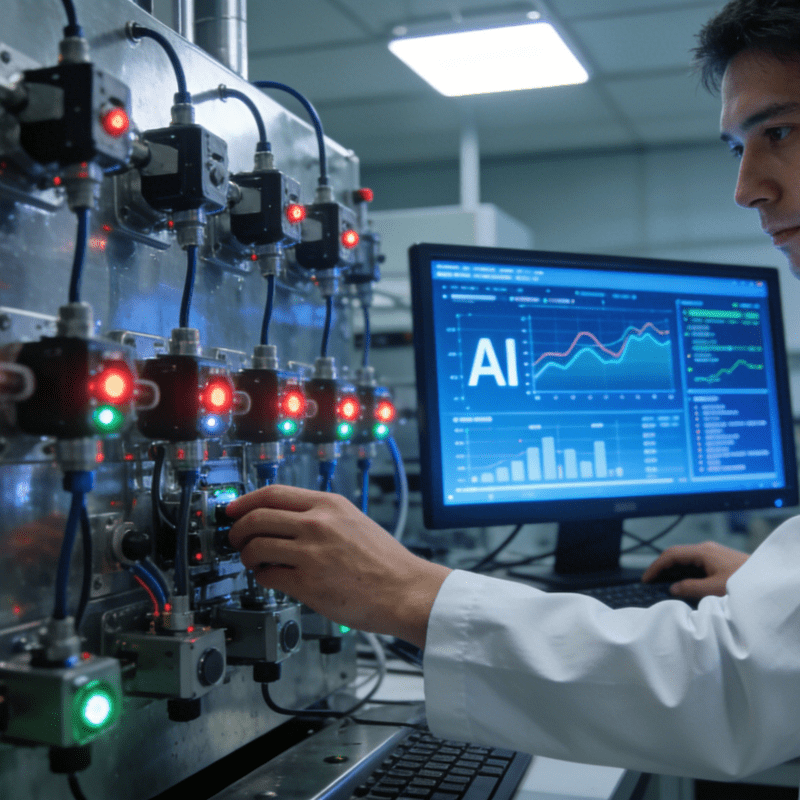

Currently, China’s industrial robot industry is in a critical transition stage from “scale expansion” to “quality improvement”. By achieving breakthroughs in technological independence, expanding diversified application scenarios, and building a global ecosystem, it is expected that by 2030, China will establish 5 world-class robot industry clusters. The localization rate of core components will exceed 90%, and the density of industrial robots will surpass 1,000 units per 10,000 people, making China a global source of robot technological innovation and a core hub for high-end manufacturing.

Automatic Assembly Machine Manufacturers

Advantages of Automatic Screw Assembly Machines