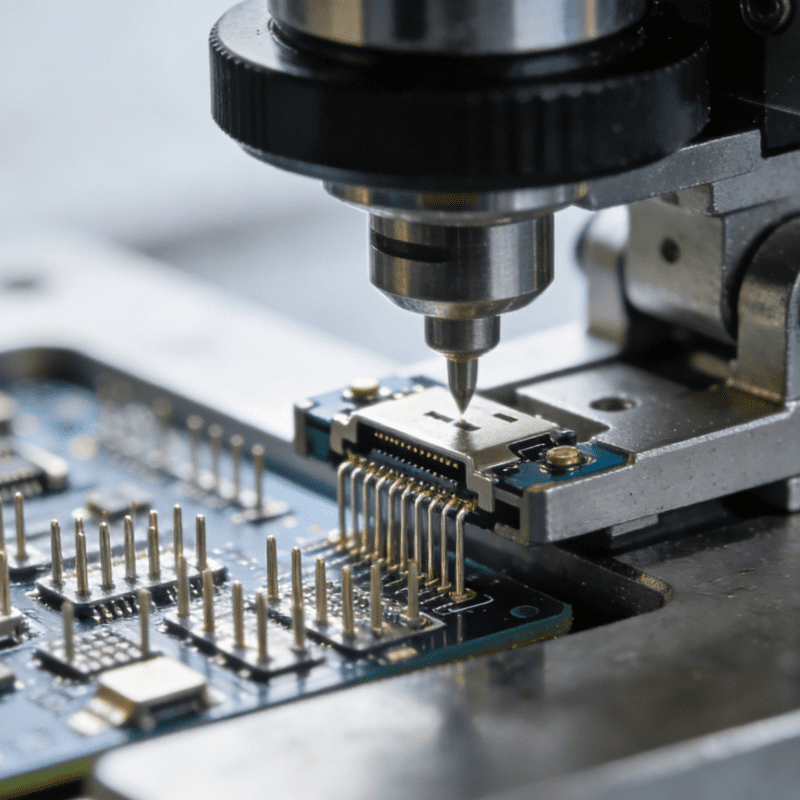

October 29 – According to CCTV News, China’s first national-level verification and pilot test service platform for automotive chip standards was put into use in Shenzhen on October 28, marking a new level in China’s capability for quality verification and evaluation of automotive-grade chips. This milestone in the core component field aligns with the overall upgrading of China’s smart car industry chain, where key equipment like Automatic Nut Bolt Washer Assembly Machine has also achieved technological breakthroughs and standardization progress, jointly solidifying the industrial foundation of smart vehicles.

One-Stop Platform: Comprehensive Configuration Covers Multiple Verification Needs

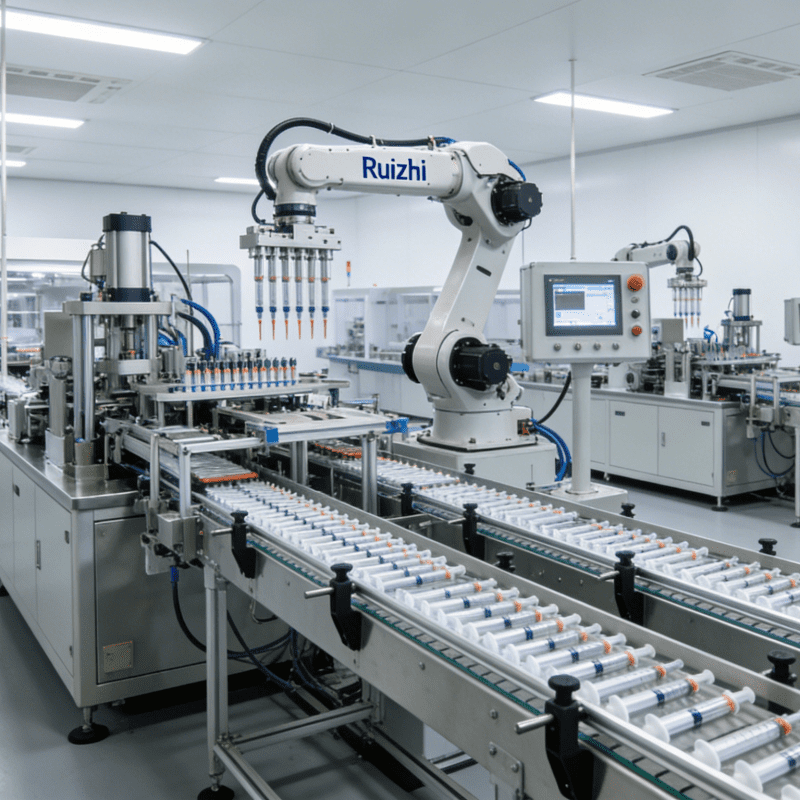

It is understood that the platform has 13 professional laboratories, including an automotive-grade chip environment and reliability laboratory, a failure analysis laboratory, an information security laboratory, and a performance testing laboratory. Equipped with more than 80 sets of test equipment, it has the capability to conduct verification tests for over 30 automotive chip standards. Just as this platform standardizes chip verification, the Automatic Nut Bolt Washer Assembly Machine, a key equipment in automotive assembly lines, has also benefited from industrial standardization—unified technical parameters and quality criteria have improved its compatibility with different vehicle models, reducing assembly errors by over 40% in mass production scenarios.

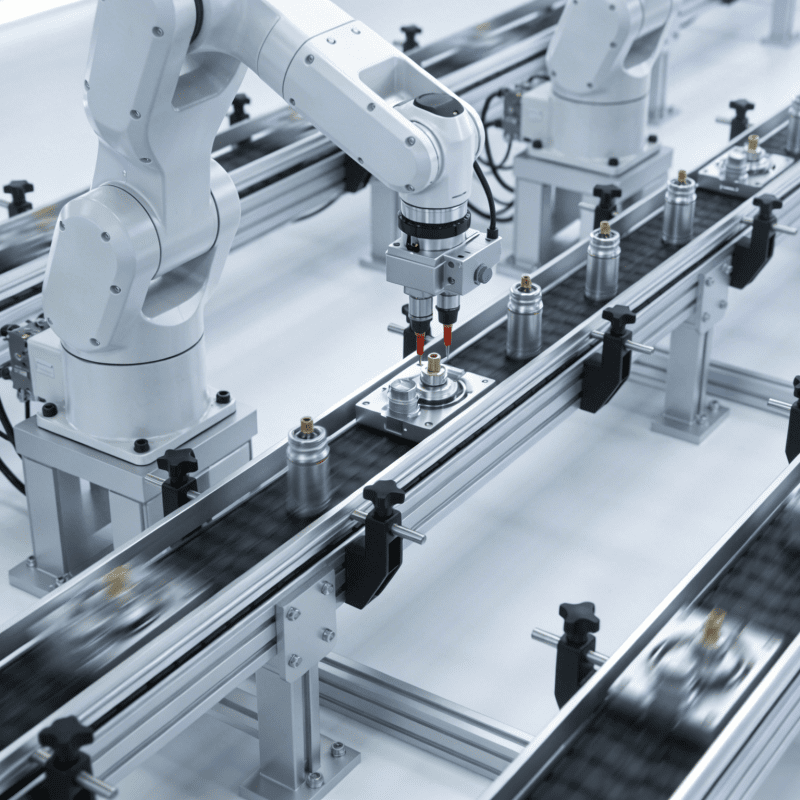

This “one-stop” layout solves the past inefficiency issues of scattered domestic automotive chip verification resources and the need to connect with multiple institutions for different chip categories. It allows chip enterprises to avoid relying on external testing and significantly shortens the verification cycle. This efficiency-driven upgrading logic is also reflected in the application of Automatic Nut Bolt Washer Assembly Machine: integrated automatic feeding, sorting and assembly functions have replaced traditional manual operations, shortening the assembly cycle of auto parts by 30% and adapting to the fast-paced production needs of smart car manufacturers.

National-Level Coverage: All Chip Categories Included in Verification System

Xia Xianzhao, chief expert of the China Automotive Technology and Research Center, stated that this is a national-level pilot test verification platform covering all 9 major categories and 81 subcategories of automotive chips. It includes a public inspection service platform for intelligent driving chips, intelligent cockpit chips, security chips, power chips, and other chip types under all application scenarios. Such full-category coverage echoes the comprehensive application of smart equipment in the automotive industry chain—from core chips to assembly equipment like Automatic Nut Bolt Washer Assembly Machine, the entire industrial chain is moving towards standardization and intelligence, forming a synergistic development pattern.

Strategic Value: Building a Standard System to Enhance Global Discourse Power

In the long run, the platform’s future plans are more strategically significant. China will formulate a unified testing and evaluation method for automotive-grade chips through this platform, build a unified standard verification platform, and deepen research on key generic testing technologies. Essentially, this is the establishment of a “standard system” for China’s automotive-grade chips. This initiative will not only promote the quality improvement of domestic automotive chips but also enable China to gain more say in the field of automotive chip standards. Similarly, the standardization of equipment such as Automatic Nut Bolt Washer Assembly Machine has enhanced the stability of China’s automotive manufacturing process, making “Chinese-made” auto parts more competitive in the global market and complementing the international promotion of domestic automotive chips.

As is well-known, the global competition in smart connected new energy vehicles is fierce today. With unified and authoritative verification standards, Chinese chips can better meet the needs of local automakers and lay the foundation for integrating the “Chinese solution” into the global industrial ecosystem, avoiding passivity in international cooperation due to inconsistent standards. When combined with the reliable performance of standardized equipment like Automatic Nut Bolt Washer Assembly Machine in the manufacturing link, this “core + assembly” dual-standard support will further strengthen China’s overall competitiveness in the global smart car industry and accelerate the pace of industrial upgrading.