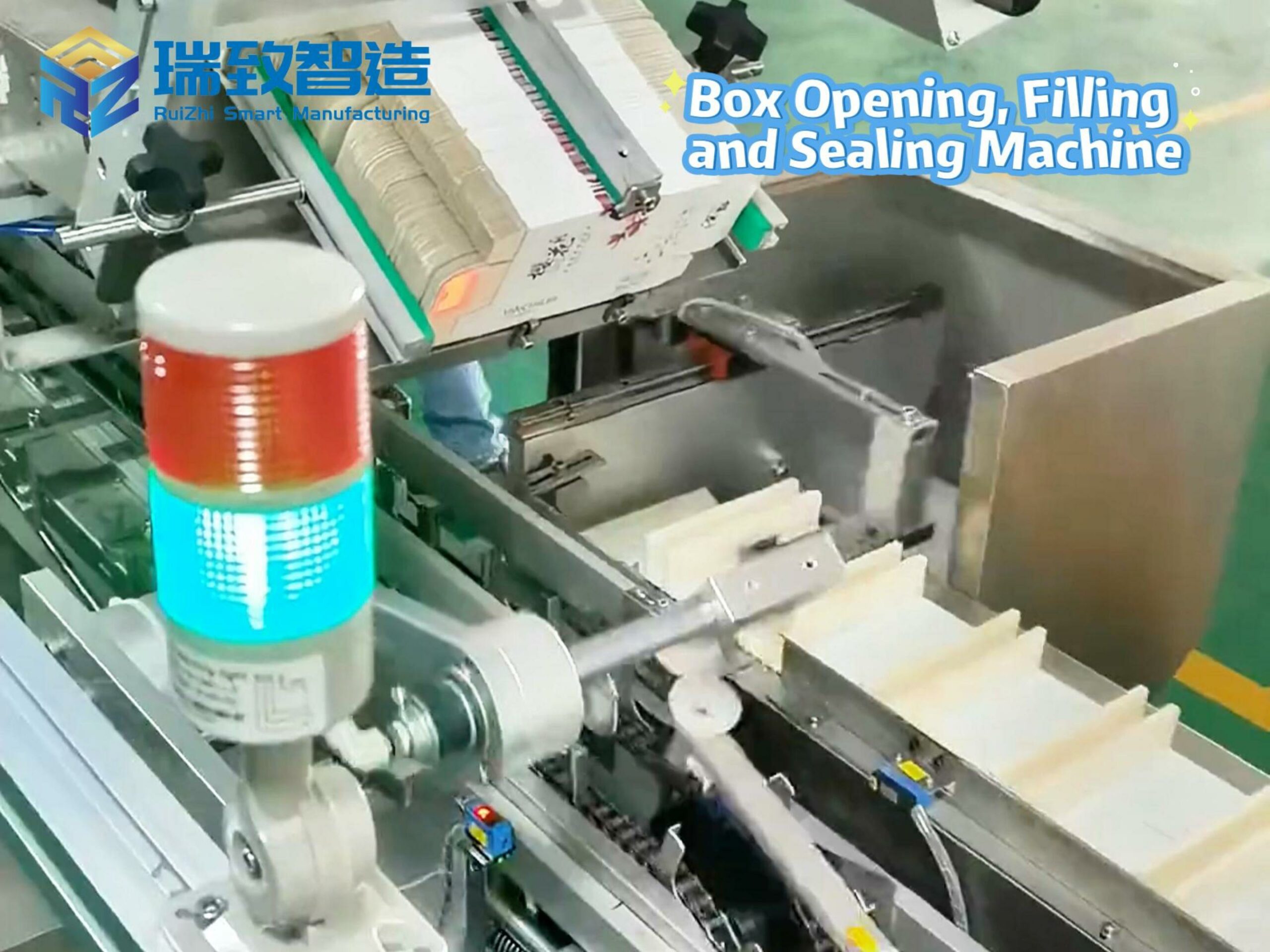

Traditional packaging methods rely on manual labor to complete processes such as case erecting, flap folding, and bottom sealing. This approach not only suffers from low efficiency but also leads to issues like dimensional deviations and insecure seals. Modern case erectors and sealers, through the in-depth integration of PLC control systems and servo drive technology, have achieved full-process automation. As a key piece of equipment connecting production and logistics, case erectors and sealers are redefining efficiency standards in the packaging process with their high efficiency, precision, and flexibility. They are not only a powerful tool for reducing labor costs but also a core element in ensuring product transportation safety and enhancing enterprise competitiveness.

Economic and Efficiency Advantages: Alleviating Labor Pressure and Boosting Productivity

Against the backdrop of annual increases in labor costs, the economic value of case erectors and sealers has become increasingly prominent. Take food enterprises as an example: traditional manual packaging requires 20 operators, with annual labor costs exceeding 2 million yuan. After introducing a fully automated case erecting and sealing line, only 3 inspectors are needed, and the production capacity of a single line increases from 800 units per hour to 1,500 units. More importantly, the equipment’s ability to operate continuously 24 hours a day allows enterprises to flexibly respond to order fluctuations and avoid production losses caused by labor shortages.

Quality Assurance and Industry Adaptability: Meeting Diverse and Rigorous Demands

Packaging quality directly affects product transportation safety and customer experience. Manual case sealing often results in carton deformation due to uneven tape winding and improper flap folding. In contrast, case erectors and sealers, through standardized operating procedures, increase the case sealing qualification rate to over 99.7%. The tension control system they adopt can automatically adjust the tape feeding speed to ensure uniform force on each meter of tape; the flap folding mechanism, designed with cam transmission, precisely controls the closing angle of carton flaps, completely eliminating the randomness of manual operations.

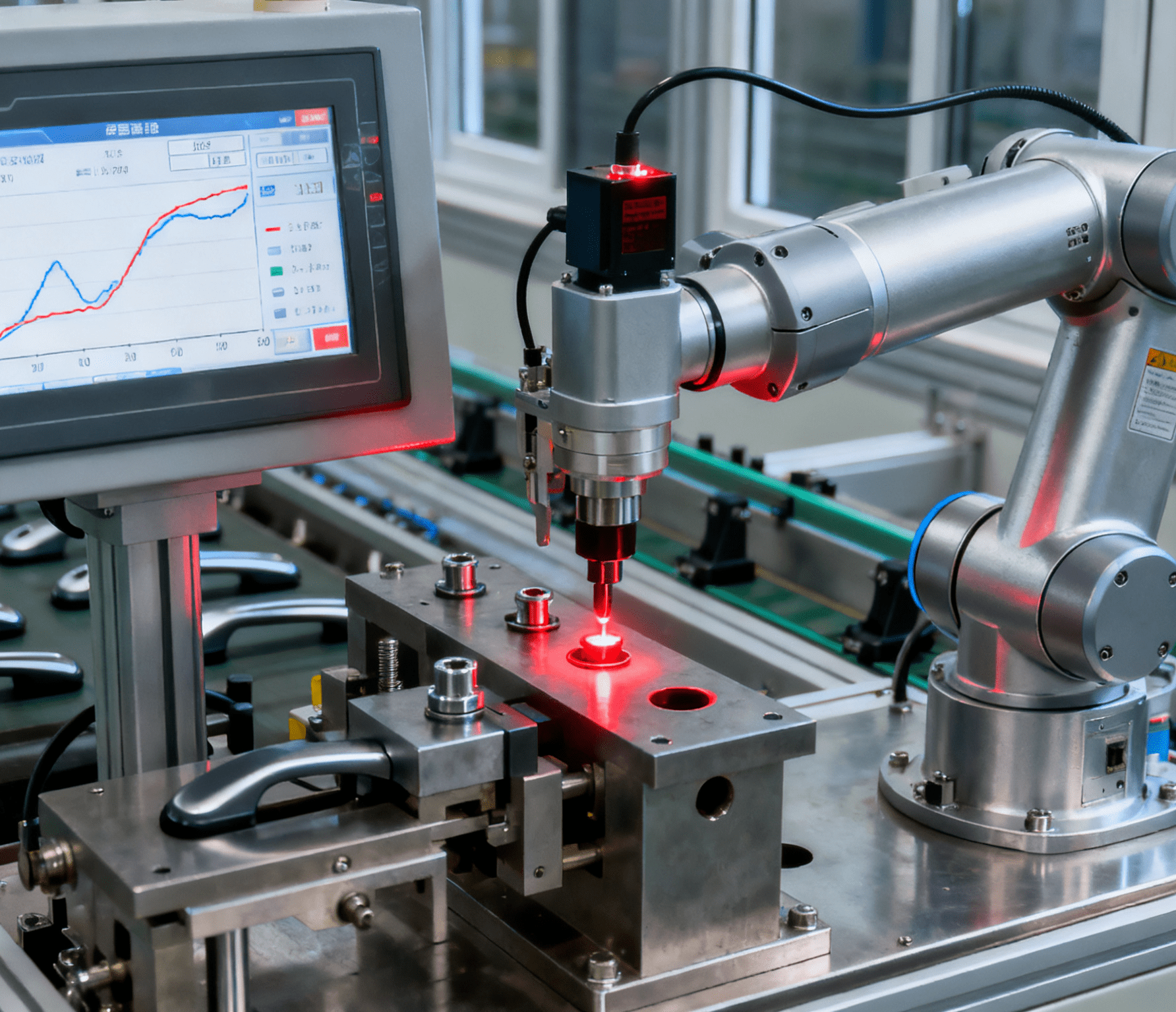

In scenarios where packaging involves small hardware components—such as electrical appliances or automotive parts—the Automatic Circlip Feeding System works in tandem with case erectors and sealers to enhance overall line precision. This system uses vibration bowls and servo-driven sorting mechanisms to orient and feed circlips (small retaining rings critical for component assembly) into packaging cases with sub-millimeter accuracy. By integrating with the sealer’s PLC, it synchronizes feeding with case movement, ensuring circlips are placed exactly where needed—eliminating misplacements that could damage products during transit. This synergy is particularly valuable for high-precision industries like electronics, where even minor component shifts can compromise product integrity.

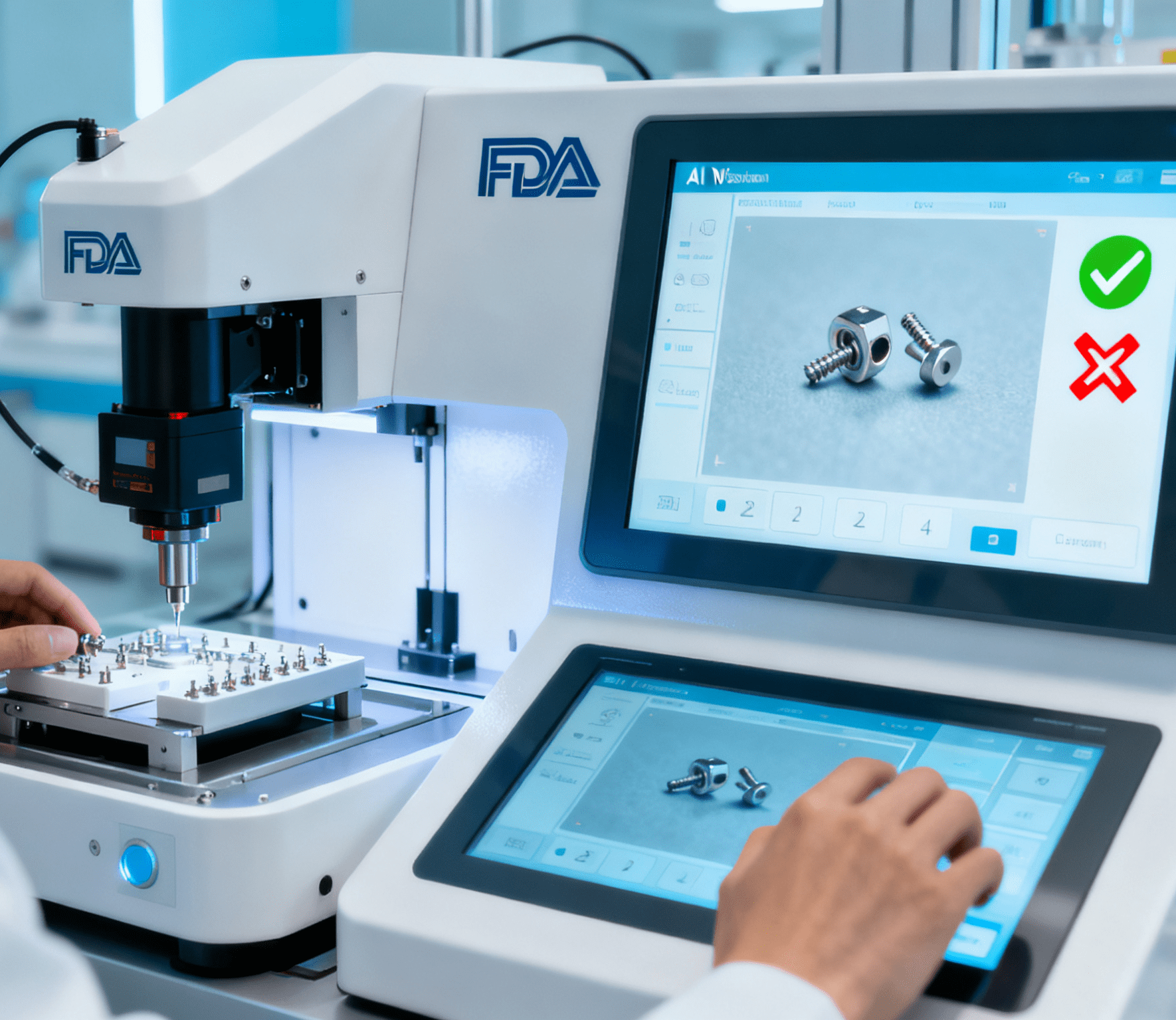

In fields with extremely high cleanliness requirements, such as pharmaceutical packaging, the contactless design of case erectors and sealers offers even greater advantages. The closed case erectors used by pharmaceutical enterprises, equipped with a negative pressure environment and ultraviolet disinfection modules, reduce the risk of microbial contamination in the packaging process by 90%, meeting the strict standards of GMP certification. This quality control capability significantly enhances the competitiveness of enterprises’ products in the international market.

In response to production demands for small batches and multiple varieties, the modular design of case erectors and sealers demonstrates strong adaptability. By replacing forming molds and adjusting program parameters, the equipment can switch from processing mobile phone boxes to refrigerator packaging boxes within 10 minutes.

Intelligent Evolution and Strategic Value: Becoming a Fulcrum for Digital Transformation

Case erectors and sealers are evolving from standalone equipment to intelligent packaging units. Leading enterprises have begun to provide integrated solutions encompassing equipment, software, and services. These solutions can remotely monitor the operating status of thousands of devices worldwide through IoT technology, provide early warnings of potential faults, and convert equipment data into production optimization recommendations.

From mechanical replacement to intelligent collaboration, and from efficiency improvement to quality control, case erectors and sealers have transcended the scope of traditional equipment and become a key fulcrum for enterprises’ digital transformation. Faced with the dual pressures of rising labor costs and increasingly personalized customer demands, choosing case erectors and sealers is not just a technological upgrade, but also a strategic investment for enterprises to build long-term competitiveness. With the in-depth integration of technologies such as AI and 5G, future case erectors and sealers will surely continue to drive value leaps in the packaging industry with a more intelligent, flexible, and green posture.

What benefits does artificial intelligence bring to component assembly machines?