Springs, as “industrial joints,” are indispensable core components in automotive (shock absorbers, clutches), home appliances (temperature control valves, door hinges), and medical devices (syringe plungers, rehabilitation equipment). However, the “last mile” of spring production—finished product arrangement and tray loading—has long relied on manual operations, becoming a hidden bottleneck restricting production efficiency and quality. With the acceleration of manufacturing automation, Automatic Spring Tray Arrangement Equipment has emerged as a “problem-solver,” realizing full-process automation of spring sorting, positioning, and tray arrangement, and fundamentally solving the pain points of manual operations.

The “Invisible Cost” of Manual Spring Arrangement: Three Core Pain Points Plaguing Enterprises

For decades, manual arrangement has been the mainstream mode for spring tray loading, but with the upgrading of product precision requirements and the rise of labor costs, its limitations have become increasingly prominent, even forming “invisible costs” for enterprises:

- Efficiency Bottleneck: “Slow Speed + Low Capacity” Can’t Keep Up with Production Rhythms

Spring arrangement requires workers to manually sort springs by specification (diameter, length), distinguish directions (e.g., compression springs with different end faces), and place them neatly in trays. A skilled worker can only process 4,000-5,000 springs per day, and filling a single tray (holding 300-500 springs) takes 15-20 minutes. In contrast, a spring production line with 2-3 stamping machines can output 20,000-30,000 springs per day—manual arrangement often becomes the “blocking point” of the entire production chain. A domestic automotive spring manufacturer once revealed that due to insufficient arrangement capacity, 20% of finished springs had to be stored in temporary warehouses, increasing inventory costs by $80,000 per year.

- Precision Risk: “Human Error” Leads to Secondary Rework

High-precision springs (e.g., automotive valve springs, medical micro-springs) have strict requirements for arrangement direction and spacing: reverse placement will cause assembly jams, and uneven spacing will damage springs during transportation. However, manual operation is affected by visual fatigue and operational habits: the error rate of direction misplacement is about 3-5%, and the spacing deviation often exceeds 1mm. These defects are not discovered until the downstream assembly link, requiring workers to re-sort and arrange, resulting in 15-20% of invalid labor costs. A home appliance parts factory calculated that manual arrangement caused 12,000 defective spring trays per year, with rework and scrap losses exceeding $120,000.

- Cost Pressure: “Labor Shortage + Rising Wages” Eats into Profit Margins

Spring arrangement is repetitive physical labor—workers need to sit for a long time, repeatedly pick and place small springs, leading to high fatigue and low willingness of young workers. The turnover rate of arrangement workers in the industry is as high as 25% per year, and enterprises often face “recruitment difficulties.” Calculated at an average monthly salary of $800, a production line needs 3-4 arrangement workers, with an annual labor cost of $28,800-$38,400. In addition, enterprises need to invest in anti-fatigue workbenches, lighting, and other auxiliary facilities, further increasing operating costs.

Automatic Spring Tray Arrangement Equipment: Four Core Functions to Build an “Intelligent Arrangement Closed Loop”

High-quality Automatic Spring Tray Arrangement Equipment is not a simple “mechanical replacement of labor,” but a systematic solution integrating “material handling, precision positioning, continuous operation, and data management.” Its core functions target the pain points of manual operation, forming a seamless production link:

- Automatic Feeding: Multi-Specification Adaptation, Zero Card Material

The feeding module is the “starting point” of the equipment, solving the problem of manual material handling and card material:

Vibratory Bowl Feeding: According to the shape (compression, extension, torsion springs) and size (diameter 2-50mm, length 5-100mm) of springs, a customized vibratory bowl is designed. Through high-frequency vibration, springs are automatically sorted into the correct direction (e.g., “large end down” for stepped springs) and conveyed to the next station.

Anti-Card Material Design: The feeding channel is equipped with a photoelectric sensor and an adjustable baffle. When springs stack or block the channel, the sensor triggers an alarm, and the baffle automatically adjusts the feeding speed or reverses the vibration to control the card material rate below 0.1%. For micro-springs (diameter <5mm), a vacuum suction auxiliary device is added to avoid spring deformation during transportation.

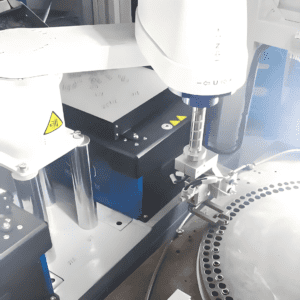

- Vision + Mechanical Positioning: Precision up to ±0.1mm, Zero Misplacement

The positioning and arrangement module is the “core” of the equipment, ensuring the precision of spring placement:

High-Definition Vision Recognition: A 20-megapixel industrial camera and AI image algorithm are used to capture the real-time position of the tray and the posture of the spring. The system can identify subtle differences in spring ends (e.g., flat end vs. rounded end) and calculate the optimal placement coordinates, with a direction recognition accuracy of 99.99%.

Servo-Driven Mechanical Arrangement: A servo motor controls the mechanical claw or push plate to place the spring in the preset position of the tray. The movement accuracy of the mechanical structure is ±0.05mm, and the final arrangement spacing deviation is controlled within ±0.1mm—fully meeting the precision requirements of automotive-grade and medical-grade springs.

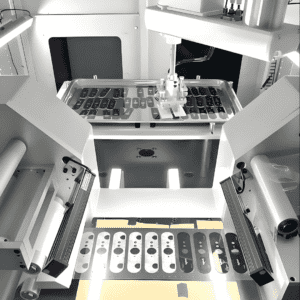

- Automatic Tray Changing: 24-Hour Continuous Operation, No Interruption

The tray changing module solves the problem of manual tray replacement leading to production downtime:

Multi-Station Tray Storage: The equipment is equipped with 2-4 tray stations and an automatic tray library (capacity 50-100 trays). When one tray is full, the system automatically moves the full tray to the discharge conveyor and transfers an empty tray to the arrangement station, with a switching time of only 10-15 seconds.

Unmanned Operation Support: With the automatic tray library, the equipment can run continuously for 24 hours without manual intervention. Even in night shifts, it only needs 1 worker to supplement empty trays occasionally, greatly improving the utilization rate of the production line.

- Data Monitoring and Traceability:

The data management module helps enterprises realize the digitization of the arrangement process, which is impossible with manual operation:

Real-Time Data Display: The equipment is equipped with a touch screen and a PLC control system, which can display key indicators in real time, such as daily output, arrangement accuracy, equipment operating status, and card material times.

MES System Docking: Through Ethernet or 4G, the equipment uploads production data (e.g., the arrangement time, tray number, and operator of each batch of springs) to the enterprise’s MES system. When quality problems occur, it can trace back to the specific equipment and time, reducing the scope of rework.

Core Technical Highlights: The “Hard Strength” That Determines Equipment Performance

The gap between high-quality and ordinary Automatic Spring Tray Arrangement Equipment lies in core technologies. These technologies ensure the equipment’s stability, flexibility, and cost-effectiveness in long-term operation:

- Flexible Changeover Technology: “One Machine for Multiple Specifications” to Adapt to Small-Batch Orders

In the context of “multi-variety, small-batch” production in the manufacturing industry, the equipment’s changeover efficiency directly affects production responsiveness:

Parameterized Setting: The touch screen can store 100+ sets of spring arrangement parameters (diameter, length, direction, spacing). When switching products, workers only need to call the preset parameter group, and the system automatically adjusts the vibratory bowl vibration frequency, vision recognition parameters, and mechanical movement path—changeover time is shortened to 5-10 minutes (traditional manual adjustment takes 1-2 hours).

Quick-Change Fixtures: The tray positioning fixture adopts a quick-release structure. When replacing trays of different sizes (e.g., 300mm×200mm vs. 400mm×300mm), the fixture can be disassembled and replaced in 2 minutes, without secondary calibration.

- Anti-Interference Mechanical Structure: Stable Operation in Complex Workshop Environments

Workshop dust, oil pollution, and vibration are the main causes of equipment failure. High-quality equipment solves this problem through structural optimization:

Protective Design: The equipment shell adopts IP54 protection level, and the key components (vibratory bowl, servo motor, camera) are equipped with dust-proof and oil-proof covers to prevent dust and oil from entering the internal structure.

Shock Absorption Design: The equipment base is made of high-density cast iron (weight ≥400kg) to reduce overall vibration; the arrangement platform is equipped with rubber shock absorbers, which can filter out 85% of workshop vibration (frequency 50-200Hz), ensuring the stability of the vision system and mechanical movement.

- Energy-Saving Design: Reduce Long-Term Operating Costs

Energy consumption is an important part of the equipment’s life-cycle cost. High-quality equipment adopts multiple energy-saving measures:

Variable Frequency Control: The vibratory bowl and conveyor belt use variable frequency motors, which automatically reduce the speed when the feeding amount is sufficient, reducing energy consumption by 20-30% compared with fixed-speed motors.

Intermittent Operation Mode: When there is no spring in the feeding channel, the equipment automatically enters a low-power state (power consumption reduced by 70%), and resumes normal operation immediately when springs are supplied—suitable for enterprises with unstable spring output.

Enterprise Selection Guide: Four Dimensions to Avoid “Adaptation Traps”

Many enterprises encounter problems such as “equipment cannot match their own spring specifications” or “high failure rate” after purchasing. When selecting Automatic Spring Tray Arrangement Equipment, focus on the following four core dimensions:

- Specification Adaptability: Confirm “Maximum/Minimum Compatibility”

Before purchasing, provide the manufacturer with detailed spring parameters: diameter (minimum/maximum), length (minimum/maximum), weight, and type (compression/extension/torsion). For example:

If producing large springs (diameter >30mm, weight >50g), select equipment with a large-capacity vibratory bowl and a high-torque servo motor;

If producing micro-springs (diameter <5mm, length <10mm), focus on the resolution of the vision system (≥20 megapixels) and the precision of the mechanical claw (±0.05mm).

- Stability: Priority to Manufacturers with “Industry Cases”

Stability is more important than “parameters on paper.” Ask the manufacturer to provide application cases in the same industry:

For example, if you are an automotive spring manufacturer, check whether the manufacturer has cooperated with well-known automotive parts enterprises, and understand the actual operation data (e.g., daily operation time ≥16 hours, monthly failure rate <1 time);

Check the brand of core components: servo motors (Panasonic, Siemens), vision systems (Keyence, Cognex), and PLC (Siemens, Mitsubishi) are more reliable than unknown brands.

- After-Sales Service: Focus on “Full-Life Cycle Support”

Automated equipment requires professional after-sales support. Confirm whether the manufacturer provides:

On-Site Installation and Calibration: The vision system and mechanical positioning need professional technicians to calibrate on site to ensure precision;

Operator Training: Train workers on parameter setting, daily maintenance (e.g., cleaning the vibratory bowl, replacing the sensor), and simple fault handling;

Warranty and Maintenance: The whole machine warranty is at least 1 year, and core components (servo motor, camera) are warranted for 3 years; provide 24-hour remote technical support to solve sudden faults in time.

- Digital Adaptability: Reserve Space for “Smart Factory Upgrade”

If the enterprise plans to build a smart factory in the future, select equipment that supports digital connection:

Confirm whether the equipment has OPC UA protocol or Ethernet interface, and can dock with MES, ERP, and other systems;

Check whether the equipment can output data in standard formats (e.g., Excel, CSV) to facilitate data analysis and production optimization.

Application Case: How a Automotive Spring Manufacturer Achieved “Triple Upgrade” of Efficiency, Quality, and Cost

A domestic automotive spring manufacturer (specializing in shock absorber springs and valve springs) once faced three major problems:

Efficiency: 6 arrangement workers could only process 48,000 springs per day, which was far less than the production line’s output of 80,000 springs per day;

Quality: The manual arrangement error rate was 4.2%, leading to 5,000+ defective trays per month and rework costs of $10,000;

Cost: Annual labor cost for arrangement workers was $36,000, plus inventory costs caused by delayed arrangement, totaling $116,000.

In 2024, the manufacturer introduced 3 sets of Automatic Spring Tray Arrangement Equipment, and the results exceeded expectations:

Efficiency Upgrade: Single equipment processes 32,000 springs per day, 3 sets of equipment process 96,000 springs per day—meeting the production line output. The number of arrangement workers was reduced to 2 (responsible for material replenishment and equipment monitoring), and annual labor cost was reduced by $28,800.

Quality Upgrade: The arrangement error rate dropped to 0.08%, defective trays were reduced to 40 per month, and annual rework costs were reduced by $115,200.

Cost Upgrade: The equipment’s annual energy consumption and maintenance cost was about $8,000, and the investment payback period was only 7 months.

In addition, the equipment was docked with the enterprise’s MES system, and the production manager could check the arrangement progress of each spring specification in real time, optimizing the production plan and reducing inventory by 30%.

Conclusion: Small Equipment, Big Value—The “Last Mile” Key to Spring Production Upgrade

Automatic Spring Tray Arrangement Equipment may seem like a “supporting device” in the spring production line, but it is the key to breaking through the “last mile” bottleneck. It not only solves the immediate problems of efficiency, quality, and cost for enterprises but also promotes the transformation of spring production from “manual-driven” to “data-driven”—for example, the arrangement data accumulated by the equipment can be used to optimize the spring stamping process, forming a “full-chain improvement loop.”

With the development of technologies such as 3D vision (for irregular springs) and AI predictive maintenance (for early warning of equipment failures), Automatic Spring Tray Arrangement Equipment will become more intelligent. For enterprises pursuing high-quality development, selecting this equipment is not only a “tool update” but also a “strategic layout” to adapt to the trend of intelligent manufacturing. After all, in the fierce market competition, the efficiency and quality of every link—including the “last mile” of spring arrangement—determine the core competitiveness of enterprises.