Aperture devices are key tools for creating visual wonders. From the light and dark changes of stage lighting to the precise focusing of photography lenses, aperture devices adjust the light flow to perfectly combine art and technology. However, behind these amazing effects, aperture devices need to cope with extremely harsh operating environments, and their performance and reliability depend on the continuous innovation of precision manufacturing technology.

Application and Working Principle of Optical Aperture Devices

Optical aperture devices are widely used in stage lighting, professional photography equipment and precision instruments. Their core working principle is to adjust the size of light passing through through a deformable blade structure to realize the control of brightness or focal length. In stage lighting equipment, the aperture needs to respond quickly to light changes while withstanding high temperature and high-intensity continuous use. Such strict requirements put forward extremely high standards for the material and processing technology of the aperture.

Technological Innovation: Airey’s Surface Treatment Technology

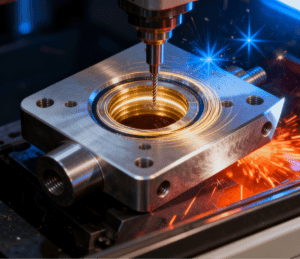

To meet the performance requirements of optical apertures under extreme conditions, Airey has introduced advanced surface treatment technologies, including Physical Vapor Deposition (PVD) and Polytetrafluoroethylene (PTFE) spraying. PVD technology adheres coating materials to the surface in the form of atoms or molecules in a vacuum environment, which not only enhances the wear resistance of the equipment but also provides excellent oxidation and corrosion resistance. At the same time, PTFE spraying, with its low friction coefficient and excellent heat resistance, ensures the smooth operation of the aperture blades and stability under high-temperature conditions.

Technological Breakthroughs and Practical Applications

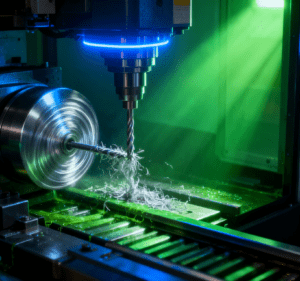

During the R&D process, our team overcame the technical difficulties of high-temperature resistance and wear resistance, and further optimized the performance of the aperture device. Through multiple experiments, a coating material that can maintain stability in an environment of up to 300 degrees Celsius was developed, while significantly improving the service life of the blades. Notably, in the mass production of aperture devices, we have adopted 4-axis robot automatic assembly equipment. This equipment can realize high-precision automatic assembly of key components such as aperture blades and transmission structures, with an assembly accuracy error controlled within ±0.005mm. It not only avoids assembly errors caused by manual operations but also increases the assembly efficiency by more than 50%, ensuring the consistency of product performance in batch production. These characteristics enable the optical aperture to withstand the challenges of strong light and high heat for a long time in stage lighting equipment, providing reliable technical support for the creation of light and shadow effects in stage lighting.

From material selection to surface treatment, Airey has opened up a new path for improving the performance of optical aperture devices with innovation and precision manufacturing technology. Behind the stage of light and shadow, these sophisticated technological achievements not only illuminate the possibilities of art but also demonstrate the infinite power of precision manufacturing.