In the booming wave of the modern home furnishing industry, the bathroom, as a key space in the home that combines comfort and functionality, has seen increasing attention paid to the quality of its equipment and decorations. From exquisite faucets, beautiful and practical bathroom cabinets, to complex shower systems and smart toilets, the types and designs of bathroom components are constantly being upgraded. At the same time, the manufacturing field of sanitary products is also undergoing profound changes. The bathroom component assembly machine, an advanced equipment, has emerged as the core force driving efficient and precise production in the industry.

Technological Innovation: Enhancing Assembly Efficiency in Multiple Dimensions

The bathroom component assembly machine integrates a number of cutting-edge technologies, bringing a qualitative leap to sanitary ware production. Take automatic control technology as an example; its core lies in achieving precise control of the assembly process through sophisticated programming and intelligent algorithms. In the faucet assembly process, the machine can automatically complete a series of complex operations such as valve core installation, handle assembly, and sealing treatment according to preset programs. In this process, automatic control technology ensures that each action is executed with pinpoint accuracy, greatly improving production efficiency. Compared with traditional manual assembly, the efficiency is increased several times or even dozens of times, and the stability of product quality is higher, effectively reducing the defective rate caused by human factors.

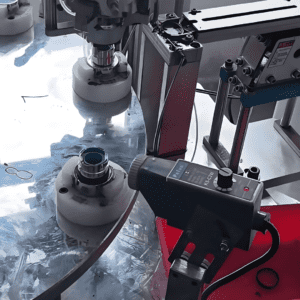

In the link of grabbing and placing components, high-precision sensors play a key role. These sensors are like the “eyes” of the machine, able to keenly perceive the position, shape, and size of components. During the assembly of bathroom cabinet laminates, sensors can accurately identify the docking position between the laminate and the cabinet, guiding the robotic arm to grab the laminate and install it in the correct position with a positioning accuracy of millimeters. This high-precision operation not only ensures the accuracy of assembly but also makes the product excellent in structural stability and appearance flatness, improving the overall quality of the product.

The advanced transmission system is the “powerful heart” for the efficient operation of the assembly machine. Using high-torque, low-noise motors and precision gear and chain transmission devices, it can provide stable and strong power output for robotic arms and other executive components. In the multi-component assembly process of shower heads, the transmission system ensures that the robotic arm moves quickly and smoothly, switching efficiently between different stations, realizing high-speed and continuous assembly operations, greatly shortening the assembly time of a single product, thus improving the overall production capacity.

Application Scenarios: Comprehensive Coverage of Sanitary Ware Production

In the field of bathroom cabinet production, the assembly machine shows strong adaptability. Bathroom cabinets usually consist of cabinets, countertops, door panels, and various storage accessories. The assembly machine can automatically complete pre-processing procedures such as plate cutting, drilling, and splicing for cabinets of different materials, such as wood, PVC, or stainless steel, then accurately install hardware accessories such as drawer slides and hinges, and finally firmly assemble the countertop with the cabinet. For bathroom cabinets of different styles and sizes, as long as the corresponding parameters are input into the control system, the assembly machine can quickly adjust the workflow to achieve personalized customized production, meeting the diverse needs of the market.

The production process of faucets is complex, and the requirements for assembly precision are extremely high. The bathroom component assembly machine has significant advantages in this field. It can automatically complete the precise assembly of valve cores, valve bodies, handles, water outlets, and other components, and real-time detect the assembly precision and tightness of each component during the assembly process. For example, after the valve core is installed, the pressure detection system is used to instantly test the water flow and sealing performance of the faucet, ensuring that the product quality meets strict industry standards. This process not only improves production efficiency but also reduces the error of manual detection, ensuring the reliability of the product.

The shower system includes multiple components such as shower heads, shower brackets, water pipes, and water distributors, and the assembly process is cumbersome. Through multi-station collaborative work, the assembly machine can quickly and accurately complete the assembly and connection of various components. The robotic arm first assembles the shower head with the bracket, then installs the water pipe and water distributor, and conducts an overall sealing test. Throughout the process, the machine can flexibly adjust the assembly sequence and process according to the design requirements of different shower systems, achieving efficient and stable production, and providing strong support for enterprises to mass-produce various shower systems.

Market Impact: Reshaping the Pattern of Sanitary Ware Production

For sanitary ware manufacturers, the introduction of bathroom component assembly machines has brought significant cost advantages. On the one hand, automated assembly has greatly reduced reliance on manual labor, lowering labor costs. Take a medium-sized sanitary ware production line as an example; after using the assembly machine, dozens of front-line assembly workers can be reduced, saving millions of yuan in labor costs every year. On the other hand, the improvement of production efficiency has significantly increased the output per unit time, spreading out fixed costs such as equipment depreciation and site rental, thereby reducing the comprehensive production cost of products and improving the profit margin of enterprises.

As consumers’ requirements for the quality and personalization of sanitary products increase, market competition has become increasingly fierce. Enterprises that can quickly respond to market demands and provide diversified, high-quality products will gain a competitive advantage. With its flexible programming control and high-precision assembly capabilities, the bathroom component assembly machine enables enterprises to quickly adjust production plans and produce personalized sanitary products that meet the needs of different consumers. For example, enterprises can quickly realize customized production through the assembly machine according to customers’ special requirements for the color, material, size, and internal storage structure of bathroom cabinets, thus standing out in market competition and winning more customer resources.

In the mass production of sanitary products, the stability of quality is crucial. The bathroom component assembly machine strictly controls the assembly quality of each product through standardized and automated assembly processes, avoiding quality fluctuations caused by factors such as fatigue and differences in technical levels in manual operations. This enables enterprises to continuously output high-quality products and establish a good brand image. Stable product quality also helps reduce after-sales maintenance and return costs, further improving the economic benefits and market reputation of enterprises.

Industry Outlook: Continuous Innovation Leading Development

With the continuous advancement of science and technology, bathroom component assembly machines will develop in depth towards intelligence and flexibility in the future. In terms of intelligence, assembly machines will have stronger autonomous learning capabilities, able to automatically optimize assembly processes and parameters through the analysis of a large amount of production data. For example, when it is detected that a certain type of faucet has frequent sealing problems during assembly, the machine can analyze the reasons by itself, adjust the installation force and angle of the sealing parts, and realize self-optimization of the production process. Flexibility is reflected in the machine’s ability to more easily cope with the rapid switching production of different types and specifications of sanitary products. Through intelligent sensors and reconfigurable mechanical structures, the assembly machine can complete equipment adjustments in a short time, quickly switching from producing one style of bathroom cabinet to another, meeting the market’s demand for personalized and small-batch production.

As the concept of environmental protection becomes increasingly popular, energy conservation and sustainable development will become important directions in the research and development of bathroom component assembly machines. On the one hand, researchers will strive to reduce the energy consumption of assembly machines, adopting technologies such as high-efficiency and energy-saving motors and intelligent power management systems to reduce energy consumption during equipment operation, lower the production costs of enterprises, and meet environmental protection requirements. On the other hand, in the selection of equipment manufacturing materials, more recyclable and degradable environmentally friendly materials will be used to reduce negative impacts on the environment. For example, some shells and structural parts are made of recycled plastics or recyclable metal materials, so that these materials can be easily recycled and reused after the equipment is scrapped, realizing the recycling of resources and promoting the sanitary ware production industry to develop in a green and sustainable direction.