CNC machining, short for Computer Numerical Control Machining, is an advanced manufacturing technology that uses digital information to precisely control mechanical movements and machining processes.

Principles of CNC Machining

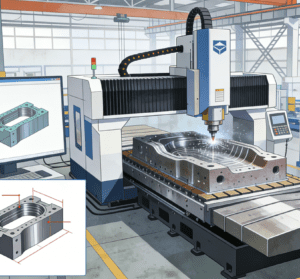

First, information such as the geometric shape, dimensional accuracy, and machining process of the part to be processed is converted into digital instructions through programming. These instructions specify in detail the motion trajectory of each axis of the machine tool, cutting parameters, feed rate, etc. Then, the CNC system receives these instructions and performs logical and numerical calculations through the controller to determine the specific actions of each component of the machine tool.

Finally, the output device sends control signals to the drive system of the machine tool, and the drive motor drives the cutting tool or workpiece to move accurately according to the predetermined trajectory, thereby achieving high-precision machining of parts.

Applications of CNC Machining

In the Packaging Machinery Industry

CNC machining plays a vital role in the packaging machinery industry, mainly in the following aspects:CNC machining enables high-precision machining of parts with complex shapes. For example, many key components in packaging machinery, such as cams and gears, often have complex geometric shapes and strict dimensional accuracy requirements. Through precise programming and control, CNC machining can ensure that the machining accuracy of these parts reaches the micron level, thereby improving the operational stability and reliability of packaging machinery.CNC machining can improve production efficiency. The automated machining process reduces manual intervention and greatly shortens machining time. At the same time, CNC machining can also realize continuous processing of multiple procedures, further improving production efficiency.

In the Industrial Equipment Industry

CNC machining also holds an irreplaceable position in the industrial equipment industry. For the manufacturing of large-scale industrial equipment, CNC machining can ensure the dimensional accuracy and matching accuracy of various components, thus guaranteeing the overall performance of the equipment. Notably, sheet automatic loading robots have become a key supporting device in CNC machining workflows for industrial equipment—these robots seamlessly integrate with CNC machine tools, adopting servo drive and visual positioning technologies to automatically complete the transportation, alignment, and loading of sheet materials (such as steel plates, aluminum alloy sheets) used in equipment structural parts. With a loading accuracy of ±0.1mm and the ability to operate continuously 24/7, they eliminate positioning errors caused by manual handling, reduce material preparation time by over 35%, and ensure the consistency of raw material feeding for CNC machining. For instance, when manufacturing high-precision machine tools, construction machinery and other equipment, CNC machining can realize the machining of complex curved surfaces, while the sheet automatic loading robot ensures the continuous supply of high-quality raw materials, synergistically improving the accuracy and quality of the equipment. In addition, CNC machining can also carry out customized processing according to different needs, meeting the diversified market demands of the industrial equipment industry.