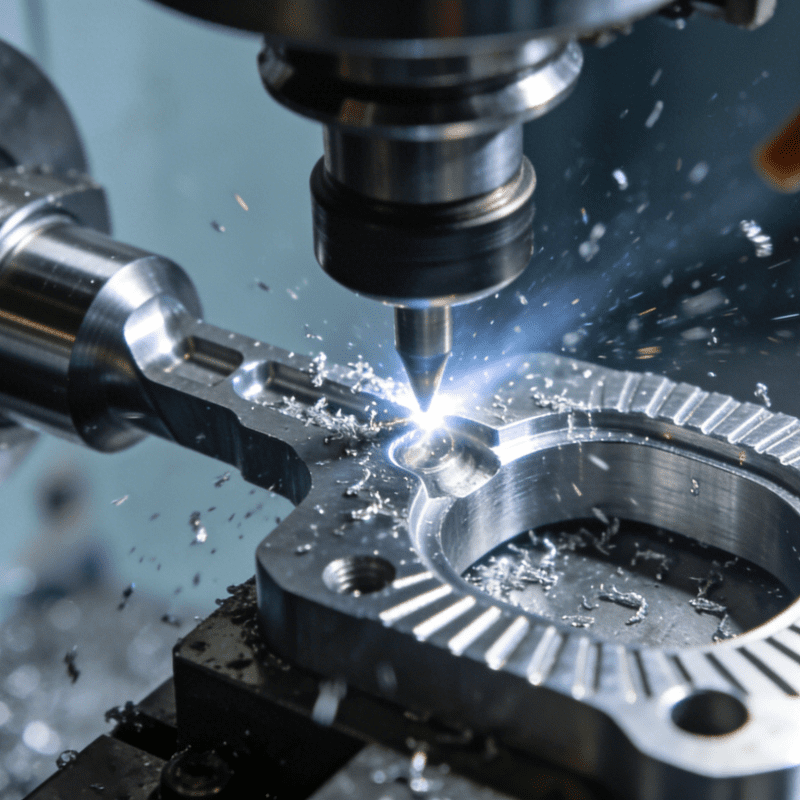

From automotive transmissions and transfer cases to fracking pumps, electronic controllers, hydraulic actuators, and refrigeration compressors, the modern world relies on highly complex electromechanical systems. These systems contain dozens, hundreds, or even thousands of precision components—all of which must fit and function perfectly to ensure product longevity, performance, and safety.

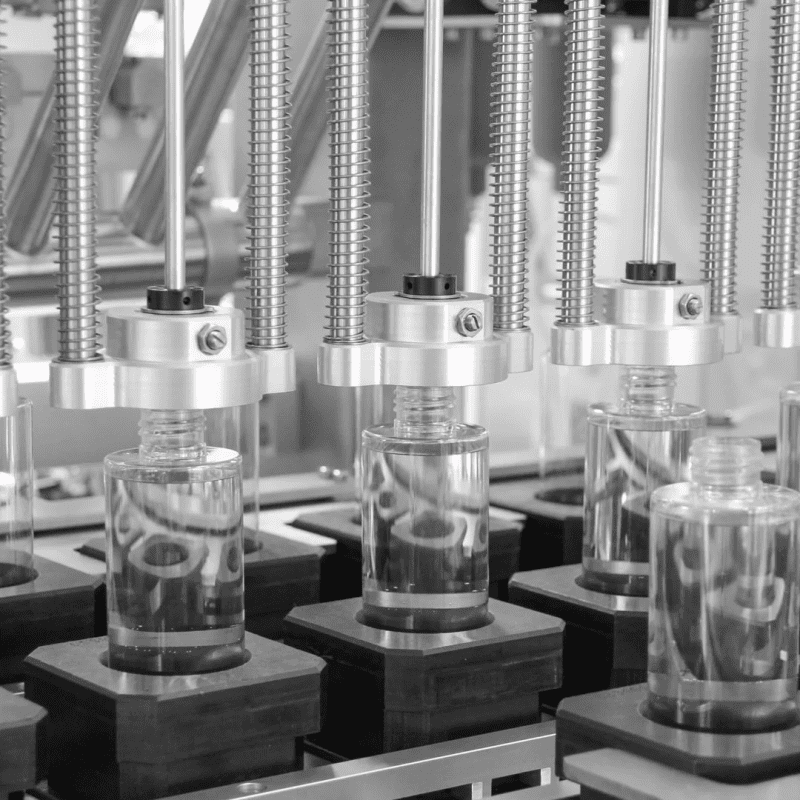

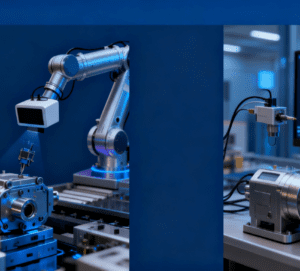

Enter automatic testing assembly machines: the backbone of reliable electromechanical manufacturing. These integrated systems combine automated assembly (via robots, dedicated machinery, or hybrid setups) with in-process and end-of-line testing, ensuring every finished device meets design specifications and avoids unexpected failures long after leaving the factory.

Why Automatic Testing Assembly Machines Are Non-Negotiable

In today’s manufacturing landscape, “fit and function” are not just goals—they’re requirements. A single misaligned component in a hydraulic actuator or a faulty connection in an electronic controller can lead to costly breakdowns, safety risks, or reputational damage.

Automatic testing assembly machines address this by embedding inspection directly into the assembly process:

In-process testing catches issues (e.g., incorrect part orientation, insufficient torque) as they occur, preventing defective components from moving to the next stage.

End-of-line testing validates full system performance—from pressure tolerance in pumps to signal accuracy in controllers—ensuring compliance with industry standards (e.g., ISO, IATF).

This integration eliminates the inefficiencies of separate assembly and testing stages, reducing rework, lowering costs, and accelerating time-to-market.

Titan Systems: 60 Years of Expertise in Automated Testing Assembly

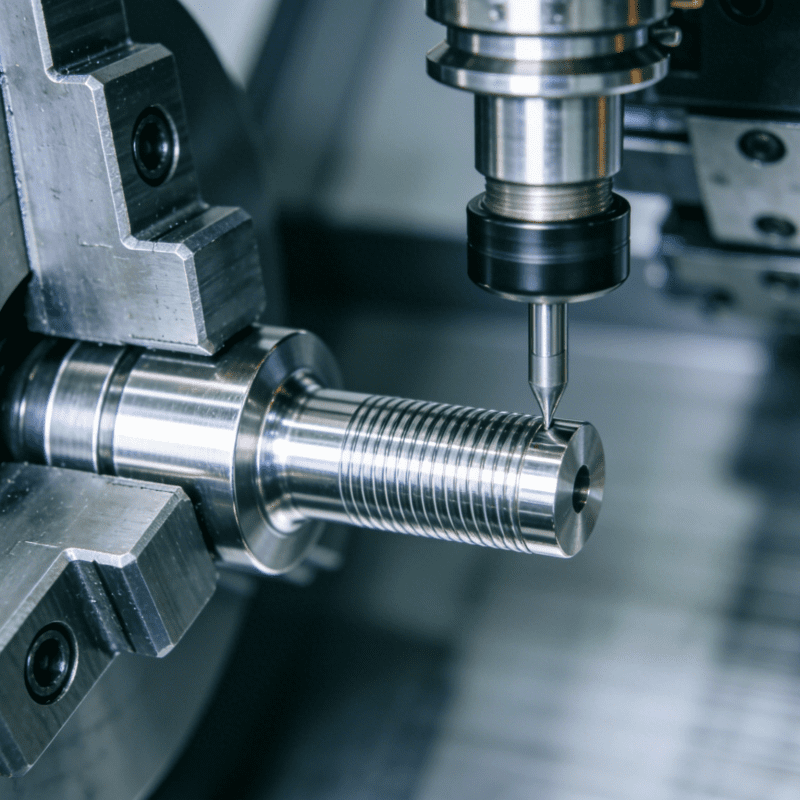

For nearly six decades, Titan Systems has been a leader in developing custom automatic testing assembly systems for manufacturers worldwide. Our team of engineers, machinists, and software developers has delivered hundreds of tailored solutions, each designed to boost throughput, enhance quality, and solve unique production challenges.

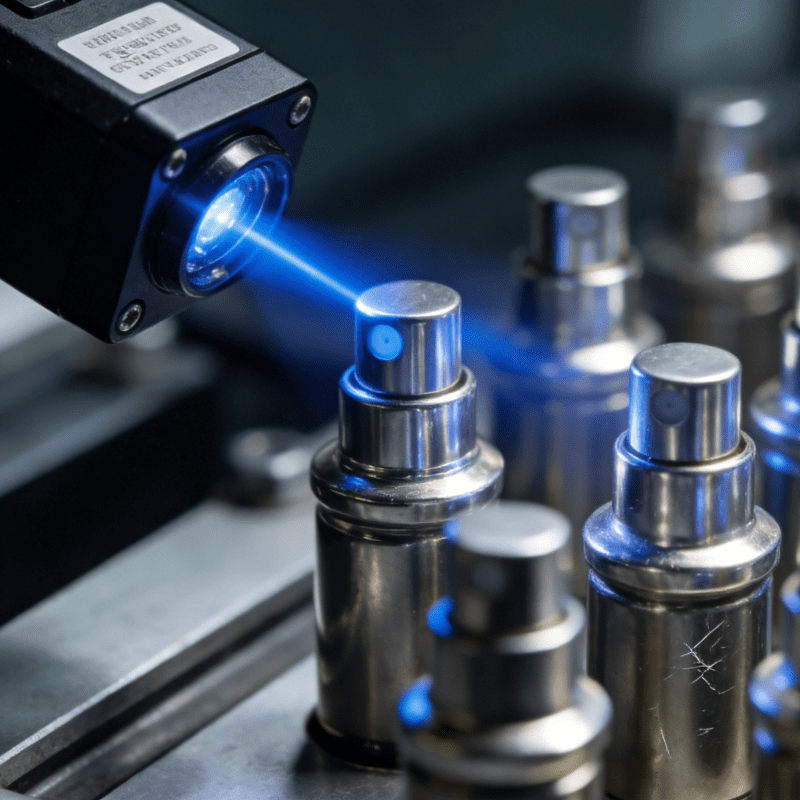

What sets our systems apart? We don’t just automate—we integrate. By embedding advanced sensor technology, real-time measurement tools, and data analytics into every machine, we create closed-loop systems that:

Detect micro-errors (e.g., 0.001mm misalignments) during assembly.

Analyze test data to identify process trends (e.g., recurring torque inconsistencies).

Empower engineers to make proactive adjustments, rather than reactive fixes.

A prime example is our 4-Axis Robotic TV Panel Screw-Fixing System, designed for high-volume electronics manufacturing. This system combines precision screw driving with in-process testing: 4-axis robotics ensure screws are driven into TV panel frames with sub-millimeter accuracy, while integrated sensors perform real-time torque verification (to prevent over-tightening or loose connections) and positional checks (to confirm each screw aligns with pre-drilled holes). By flagging issues like stripped threads or misaligned fasteners mid-assembly, the system eliminates downstream failures—critical for TV panels, where even minor structural weaknesses can lead to display malfunctions or safety hazards.

Smart Automation: Solving Labor Gaps & Driving Efficiency

The bar for manufacturing automation is rising—and for good reason. Skilled labor shortages persist globally: the U.S. Bureau of Labor Statistics reports nearly 600,000 unfilled manufacturing jobs, a trend amplified by reshoring efforts.

Automatic testing assembly machines are a strategic solution. They reduce reliance on manual labor for repetitive, precision-critical tasks while improving consistency and output. But not all automation is equal:

Generic systems may assemble parts quickly but lack the testing rigor to ensure long-term reliability.

Smart systems (like those from Titan) use data to “learn” and adapt, turning test results into actionable insights that optimize the entire production loop.

In short, smart automation isn’t just about replacing workers—it’s about empowering manufacturers to do more with less, without sacrificing quality.

Conclusion: Invest in Integrated Testing & Assembly for Competitive Advantage

In a world where electromechanical systems grow more complex by the day, automatic testing assembly machines are no longer optional—they’re essential. By merging precision assembly with real-time testing, these systems ensure reliability, reduce costs, and help manufacturers navigate labor shortages.

At Titan Systems, we’ve spent 60 years perfecting this integration. Whether you’re producing automotive components, industrial pumps, electronic controllers, or TV panels with our 4-Axis Robotic Screw-Fixing System, our custom automatic testing assembly solutions are built to solve your unique challenges—so you can build better, faster, and more reliably.

Ready to elevate your manufacturing process? Contact us to explore how automatic testing assembly machines can transform your production line.

Assembly machines suitable for the assembly of various products with robot applications