In today’s manufacturing landscape, CNC machining has emerged as a powerful driving force for industrial development, thanks to its outstanding automated advantages.

High-Efficiency Production: Continuous Operation & Rapid Machining

The automation of CNC machining is first reflected in high production efficiency. CNC machine tools can perform machining operations continuously and stably according to pre-written programs. Unlike traditional machining methods that require frequent manual adjustments and operational interruptions, CNC machining significantly reduces downtime. For example, in the mass production of auto parts, CNC machining equipment can operate around the clock, rapidly manufacturing large quantities of high-precision components. In the precision spring manufacturing industry, CNC machining centers are deeply integrated with Automatic Spring White Disc Machines: after CNC machines complete high-precision machining of spring blanks and white disc substrates (with dimensional tolerance controlled within ±0.01mm), the automated white disc machine immediately performs synchronous feeding, positioning, and assembly without manual handover. This integrated workflow realizes 24/7 continuous production of precision springs, increasing the unit-hour output by over 40% compared with traditional manual assembly lines, while ensuring consistent matching accuracy between springs and white discs. Meanwhile, the high-speed cutting capability of CNC machining is unparalleled by traditional machining processes. The high spindle speed and fast feed rate make the machining process extremely efficient, greatly shortening the processing cycle and increasing output per unit time.

Precision & Versatility: Accurate Control & Flexible Machining

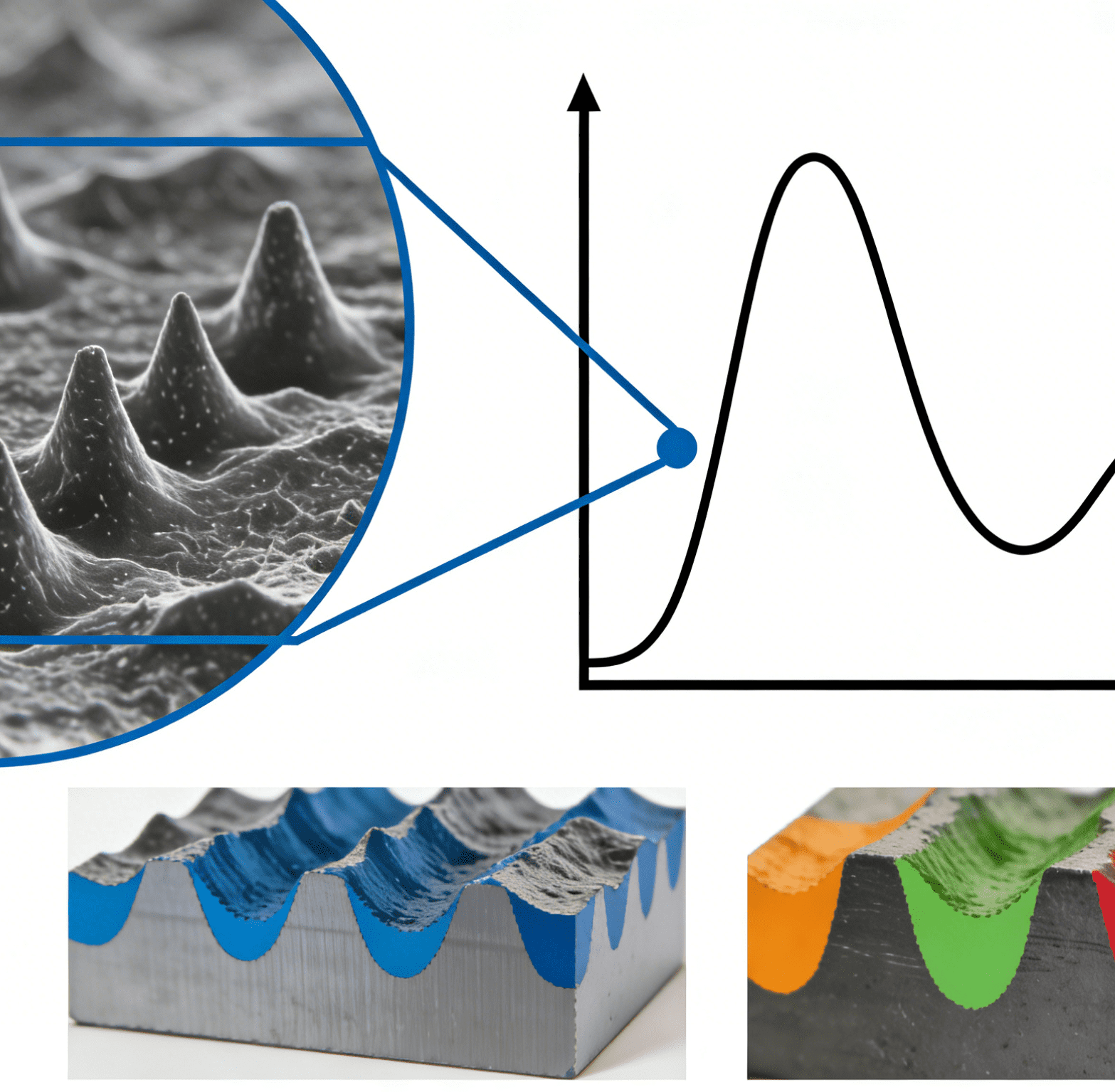

Precision control is another prominent advantage of CNC machining automation. The CNC system can precisely control the movement trajectory and position of the machine tool, ensuring machining accuracy reaches an extremely high level. Through sophisticated programming, high-precision machining of complex-shaped parts can be achieved, with errors controlled within a minimal range. Moreover, CNC machine tools are equipped with advanced feedback devices that monitor the machine’s operational status in real time. If any deviation occurs, adjustments can be made immediately to maintain consistent machining precision. This high-precision machining capability is crucial for industries with stringent accuracy requirements, such as aerospace and medical devices.

CNC machining also excels in terms of machining flexibility. Complex parts can be processed quickly through computer programming, and for different machining requirements, only program modifications are needed without replacing a large number of tooling fixtures. This ability for rapid programming and modification gives CNC machining a great advantage in new product development and small-batch, multi-variety production. In addition, the multi-axis simultaneous machining capability of modern CNC machine tools opens up unlimited possibilities for processing complex-shaped parts. For instance, a 5-axis simultaneous machining center can complete the machining of complex curved-surface parts in a single clamping, greatly improving both machining efficiency and precision.

Human-Centric & Intelligent Management: Reduced Labor Intensity & Optimized Coordination

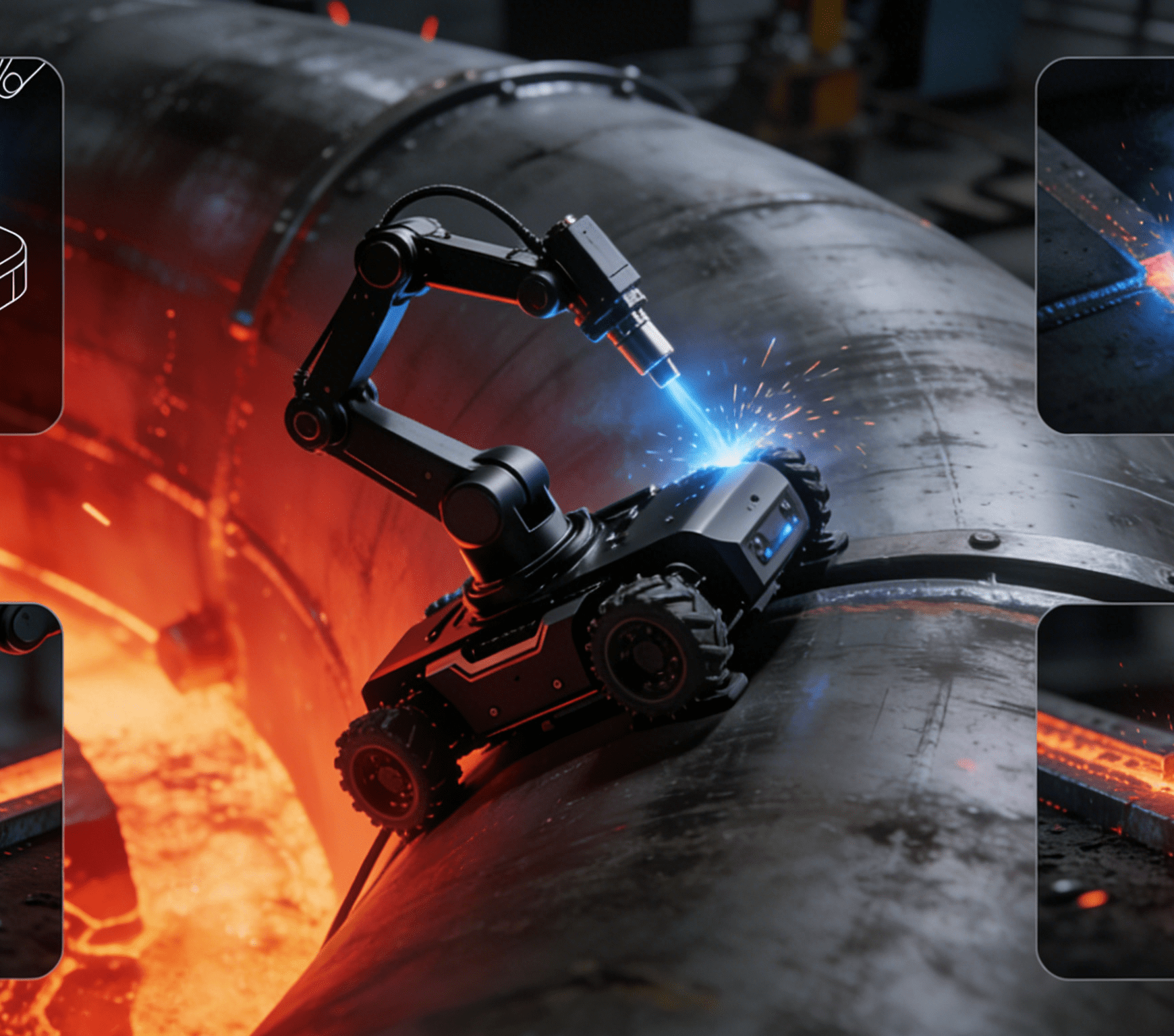

CNC machining also greatly reduces labor intensity. Traditional machining requires operators to perform heavy physical labor, and prolonged operation can easily lead to fatigue and errors. In contrast, CNC machining enables automated production, where operators only need to carry out program writing, equipment monitoring, and simple maintenance work. This not only reduces manual intervention and labor intensity but also improves the working environment. CNC machining equipment is usually equipped with excellent protective devices and chip removal systems, which can effectively reduce noise, dust, and chip splatter, providing operators with a safer and more comfortable working environment.

Finally, CNC machining facilitates production management. CNC machine tools can collect real-time production data, such as machining time, tool life, and processing quantity, providing accurate information for production management. Enterprises can analyze and optimize based on this data, arrange production plans rationally, and improve production efficiency and quality. Meanwhile, CNC machining can be integrated with other automated equipment and production management systems to realize intelligent production, enhancing production coordination and management efficiency.