Nowadays, Apple has made automation a prerequisite for awarding manufacturing contracts. This automation requirement covers Apple’s major product categories, including iPhone, iPad, Mac, and Apple Watch.

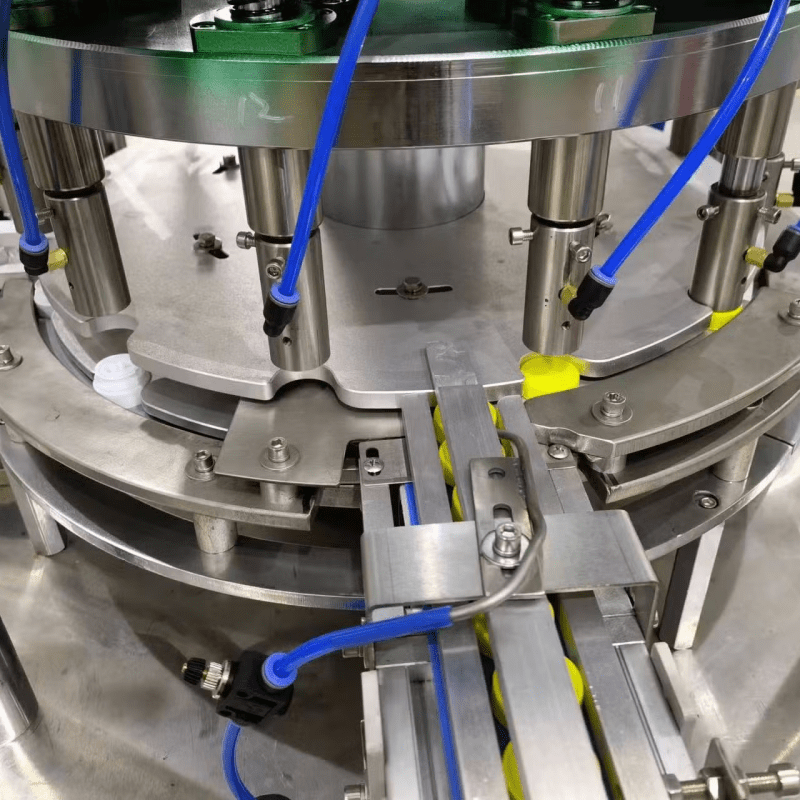

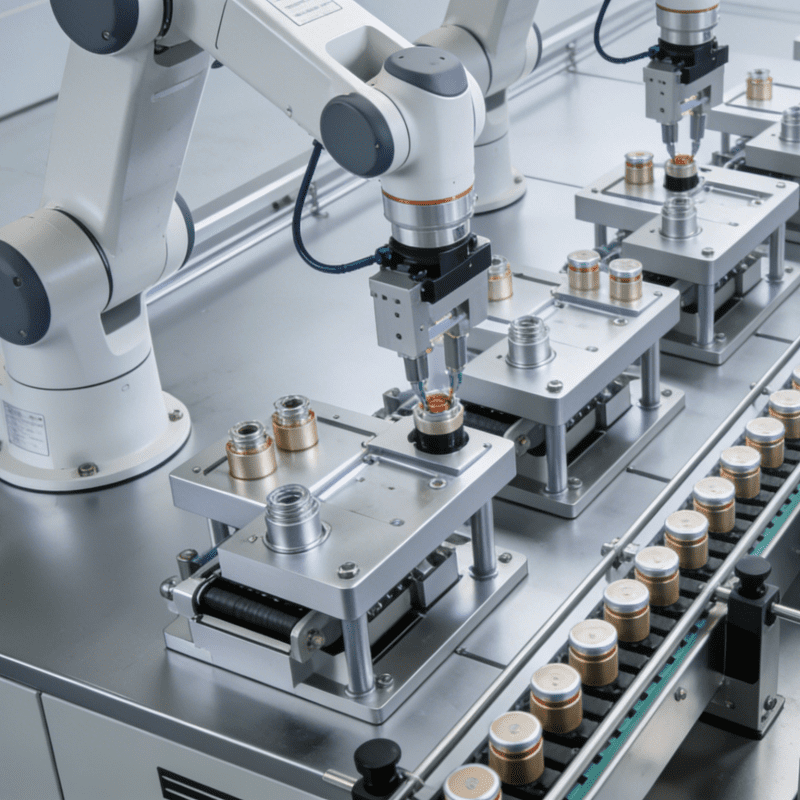

According to sources, on September 2nd, although Apple has been advocating for suppliers’ factories to improve automation levels for more than two years, it has now made automation a prerequisite for awarding manufacturing contracts. The core purpose is to reduce reliance on manual labor, ensure consistent product quality across different factories, and lower production costs.

Apple’s automation requirement covers its main product lines, including iPhone, iPad, Mac, and Apple Watch. Apple requires suppliers to bear the funds needed for automation upgrades themselves instead of relying on Apple. This change is different from Apple’s previous practice. In the past, to make contract manufacturers meet its specifications, Apple usually invested in the purchase of production tools and mechanical equipment.

Obviously, the financial burden brought by this new requirement will affect the profit margins of suppliers. Reports indicate that high capital expenditures, coupled with disruptions to production operations during the integration of robot systems, have put significant pressure on the profitability of some suppliers.

However, in areas related to environmental responsibilities, Apple will still provide assistance to suppliers. Apple has set a goal of achieving carbon neutrality across its entire supply chain by 2030, which includes directly supporting suppliers in upgrading energy-efficient equipment and adopting sustainable materials.