Anodizing Process Enhances CNC-Machined Aluminum Parts:

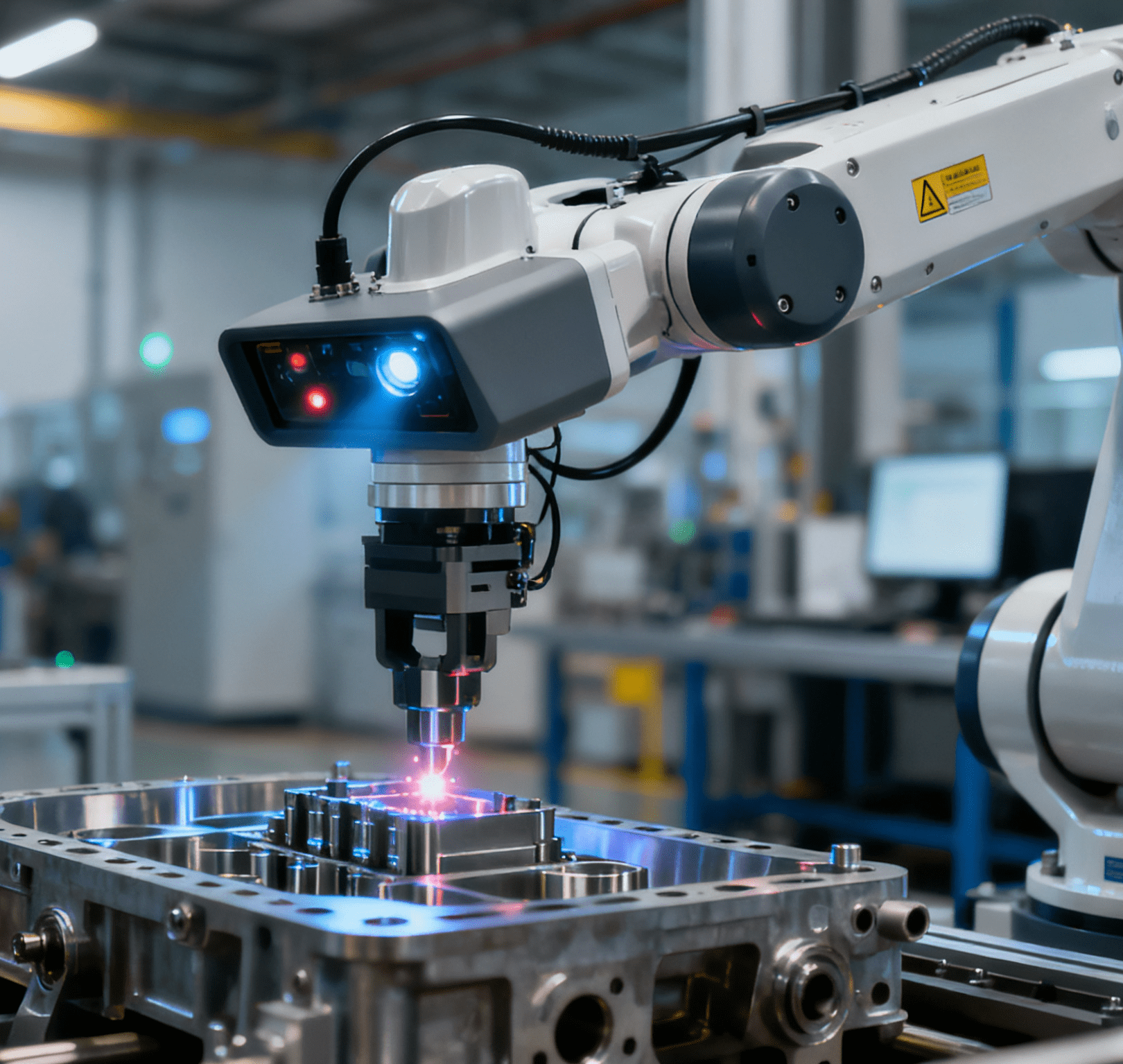

Optimizing Surface Performance and TextureThe anodizing process stands as a cornerstone in the CNC machining of aluminum parts, offering unparalleled advantages that elevate both functionality and aesthetics. By forming a thick, dense oxide film on the aluminum surface, it significantly boosts corrosion and wear resistance—enabling parts to withstand harsh environments, resist daily abrasion, and reduce long-term maintenance costs. Beyond durability, anodizing enhances surface quality: manufacturers can tailor the oxide film’s thickness and color by adjusting parameters like current density and treatment time, creating unique visual effects. When integrated with CNC machining’s precision, this process unlocks diverse design possibilities, directly addressing the manufacturing industry’s growing demand for high-quality, customizable products and driving overall industrial innovation. Notably, this synergy extends to electronic manufacturing scenarios such as TV production: the 4 – Axis Robotic TV Panel Screw – Fixing System relies heavily on CNC-machined aluminum components treated with anodization. The process’s ability to refine surface smoothness and dimensional stability ensures the aluminum brackets, frames, and mounting bases used in the robotic system maintain tight tolerances, enabling the 4-axis robot to achieve micron-level positioning accuracy during screw-fixing operations.

Underlying Mechanism:

How Anodization Improves Surface PerformanceThe efficacy of anodization stems from a controlled electrochemical reaction that generates a robust aluminum oxide film on the material’s surface. A key advantage lies in the film’s hardness, which far exceeds that of raw aluminum, forming a protective barrier against external erosion and mechanical wear. This electrochemical process also offers exceptional customization: varying anodization duration and current density produces films of different thicknesses and hues, providing versatile aesthetic options for end products. Additionally, the oxide film’s inherent microporous structure enhances its ability to adsorb coatings and dyes, laying a solid foundation for subsequent surface treatments. For the 4 – Axis Robotic TV Panel Screw – Fixing System, this hardness and structural stability are critical: the anodized aluminum parts endure repeated mechanical stress from the robot’s rapid screw-driving movements without deformation, while the smooth surface reduces friction between the robot’s clamping mechanisms and the aluminum components, prolonging the system’s service life and ensuring consistent assembly quality. Through precise control of these process variables, manufacturers can optimize both the functional performance and visual appeal of finished aluminum parts.

Synergy with CNC Machining:

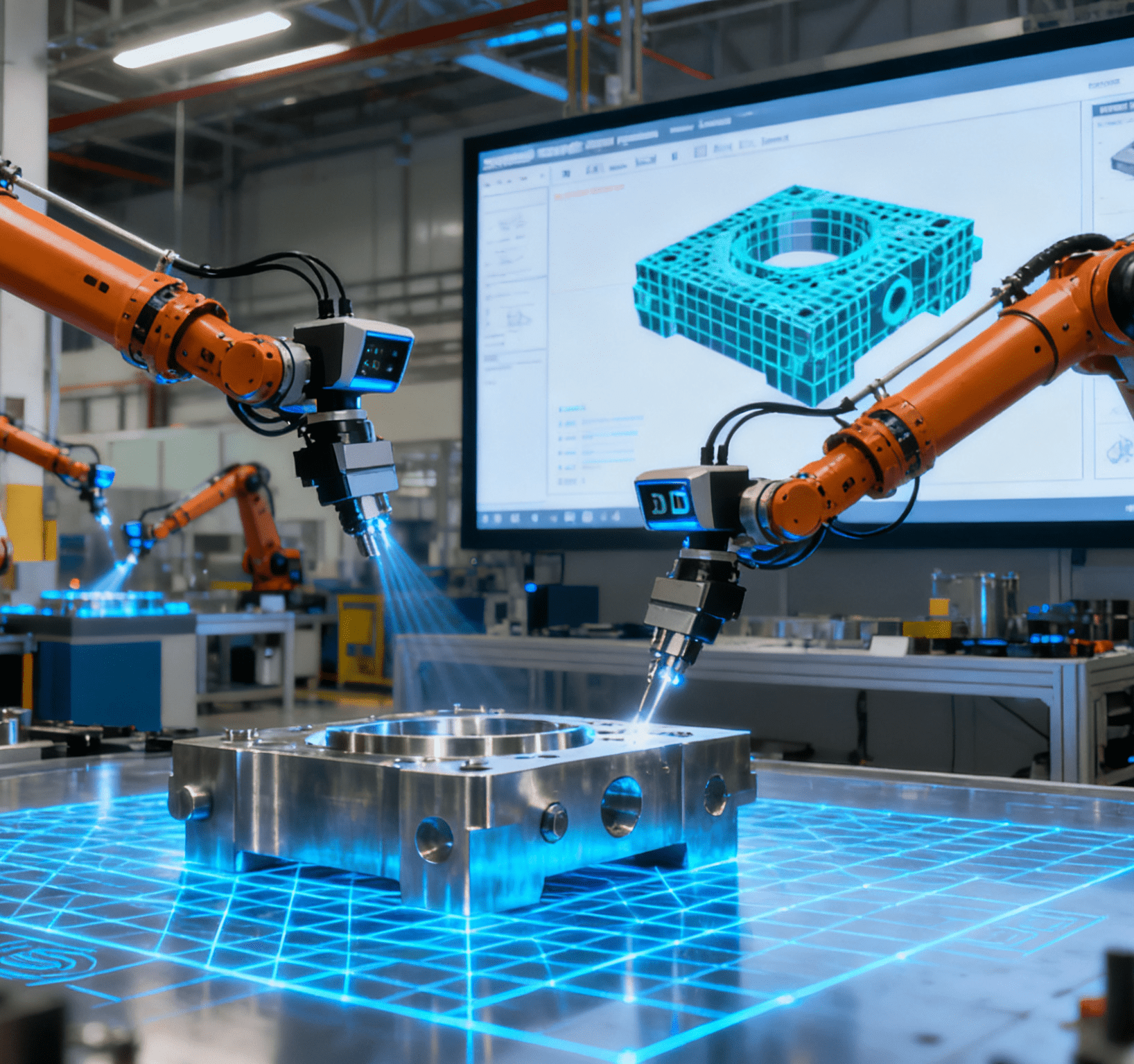

A Catalyst for High-Quality ProductionThe integration of CNC machining and anodization creates a powerful synergy that redefines aluminum part manufacturing. CNC machining delivers the precision needed to cut and shape aluminum into complex, design-specific forms, ensuring tight tolerances and consistent part geometry. Anodization then builds on this foundation by enhancing the surface properties: it increases surface thickness and strength while reinforcing corrosion resistance, transforming precisely machined components into durable, long-lasting products. This combination also elevates market competitiveness: optimized anodization processes yield superior color consistency and texture, making parts more visually striking. In the context of the 4 – Axis Robotic TV Panel Screw – Fixing System, this synergy becomes even more impactful: CNC machining crafts the aluminum parts into shapes that perfectly match the robot’s assembly trajectory, while anodization’s corrosion resistance prevents oxidation-induced dimensional changes—critical for maintaining the robot’s repeat positioning accuracy over long-term operation. As manufacturing standards continue to rise, this coordinated approach remains pivotal to meeting the demand for products that balance functionality, durability, and aesthetics.

Practical Case Studies:

Anodization in Key IndustriesAnodization’s impact is most evident in high-stakes industries like aerospace and automotive manufacturing, where performance and durability are non-negotiable. In aerospace, a leading airline implemented anodization for its aluminum alloy components, resulting in a uniform, dense oxide film that drastically improved corrosion resistance. These treated parts not only withstood extreme atmospheric conditions but also exhibited enhanced surface gloss, meeting both functional and aesthetic requirements. In the automotive sector, a major manufacturer adopted anodization for body components, rendering them resistant to environmental factors such as moisture and road debris. In electronic manufacturing, a global TV brand integrated anodized CNC aluminum parts with its 4 – Axis Robotic TV Panel Screw – Fixing System, achieving a 30% reduction in assembly errors and a 15% increase in production efficiency. The anodized aluminum mounting brackets ensured stable screw torque during panel assembly, while the process’s color customization allowed the parts to align with the TV’s internal aesthetic without additional coating steps. These cases demonstrate anodization’s ability to simultaneously boost performance and visual quality, aligning with modern consumers’ dual expectations for reliability and appeal.

Conclusion: Anodization as a Driver of Manufacturing AdvancementAnodization plays an irreplaceable role in enhancing the surface performance and texture of CNC-machined aluminum parts. Its ability to improve corrosion and wear resistance extends product lifespans, while its customizable aesthetic properties enhance market competitiveness. When paired with CNC machining’s precision, it enables the production of high-quality aluminum products that integrate functionality and visual appeal seamlessly—including critical components for specialized automation equipment like the 4 – Axis Robotic TV Panel Screw – Fixing System. As the manufacturing industry evolves, the continuous optimization of anodization processes—alongside its integration with advanced machining technologies and automation systems—will remain a key driver of innovation, providing flexible, efficient solutions to adapt to rapidly changing market demands.