Table of Contents

ToggleAnalysis of Core Technologies of Flexible Automatic Assembly Equipment: How Modular Design Reshapes Manufacturing Flexibility

Introduction

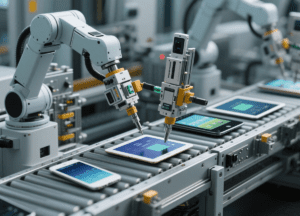

In the new manufacturing ecosystem featuring “multiple varieties, small batches, and rapid iteration,” flexible automatic assembly equipment is breaking through the “rigid shackles” of traditional production lines through modular design. This technical architecture centered on “decoupling and reconstruction” not only enables rapid replacement of hardware modules but also endows production lines with intelligent flexibility for “versatile adaptation” through software-defined logical recombination. From the three dimensions of mechanical engineering, control algorithms, and industrial software, this article analyzes how modular design evolves manufacturing systems from “customized special machines” to “universal transformers,” combined with in-depth practices in the 3C electronics, automotive parts, and medical device industries.

I. Hardware Modularization: Building a Reconfigurable Physical Foundation

1. “Lego-style” Decoupling Design of Mechanical Structures

Parametric Module Definition:

Adopting the dimensional chain design of ISO 14405-2 standard, the assembly unit is disassembled into three basic units: execution modules (robotic arms/servo slides, positioning accuracy ±0.02mm), tooling modules (adaptive fixtures, compatible with workpiece dimensional tolerances ±2mm), and logistics modules (AGV docking stations, docking accuracy ±1mm). Each module achieves 5-minute rapid replacement through standardized flange interfaces (e.g., DIN EN 60068-2-6 vibration class certification).

Industry Case: Model Switching Revolution of a US-funded 3C Enterprise:

In the assembly of smartphone motherboards, magnetic quick-change fixtures (suction force ≥500N, positioning pin accuracy ±0.01mm) reduce the model switching time from iPhone 15 to Samsung Galaxy S24 from 120 minutes to 18 minutes. The fixture reuse rate reaches 75%, and equipment investment costs are 40% lower than traditional special machine lines.

2. Flexible Upgrades of Drive Systems

Plug-and-Play Servo Units:

Using EtherCAT industrial Ethernet (transmission rate 100Mbps, synchronization error ≤1μs), it supports seamless access to servo motors of different brands (such as Panasonic MINAS A6 and Inovance IS620). In the assembly of steering sensor by a German-funded automotive electronics factory, replacing the servo driver parameter template increases the control compatibility of multi-brand motors from 60% to 95%.

Redundancy Design for Extreme Conditions:

In the assembly of lithium batteries in high-temperature environments (85℃), modular heat dissipation units (thermal conductivity ≥150W/mK) can be independently replaced. Combined with the hot-swapping technology of spare servo modules (switching time ≤0.5s), the continuous operation time of equipment is increased from 4 hours to 72 hours.

II. Software Modularization: Defining an Extensible Logical Hub

1. Breakthrough in Distributed Control Architecture

Reuse of Function Blocks Following PLCopen Standards:

Develop a process library containing over 600 function blocks (e.g., the “screw tightening” function block integrates three sub-modules: torque control, error-proofing detection, and data traceability), enabling engineers to quickly build new model programs by drag-and-drop. A domestic medical device factory thus reduces the program development time for surgical staplers from 5 days to 8 hours.

Edge Computing and Cloud Collaboration:

Edge nodes at the device end (computing power 20TOPS) handle real-time control (such as 1000Hz force control data collection), while cloud servers run complex AI algorithms (such as LSTM-based anomaly prediction models with 92% accuracy), forming a hybrid architecture of “edge real-time response + cloud continuous evolution.”

2. Module Collaboration Driven by Digital Twins

Multi-Physical Field Simulation Verification:

Construct module-level digital twins in ANSYS Twin Builder to simulate the vibration mode of robotic arms during high-speed movement (accuracy ±5%) and the stress distribution during fixture clamping (error ≤10%). A Japanese watch enterprise reduces the assembly interference risk of 0.5mm diameter gears by 80% through virtual debugging.

Dynamic Task Allocation Algorithm:

Based on a genetic algorithm-driven module load balancing model, in multi-robotic arm collaboration scenarios, high-precision assembly (±0.01mm tasks assigned to ABB YuMi) and high-speed handling (2m/s tasks assigned to KUKA KR 10) are automatically allocated. An electronics factory increases equipment overall effectiveness (OEE) from 70% to 86% through this.

III. Process Modularization: Precipitating Reusable Knowledge Assets

1. Construction of Parametric Process Packages

Three-Dimensional Process Knowledge Base:

Store over 2,000 historical process solutions in three dimensions: “workpiece characteristics (size/material) – equipment modules (robotic arms/fixtures) – process parameters (pressure/speed)”. A Taiwan-funded connector manufacturer shortens the first-piece debugging time for new products from 4 hours to 30 minutes by calling similar process packages (matching degree ≥80%).

Self-Optimizing Process Engine:

Using Bayesian optimization algorithm, the optimal crimping pressure (5-15N) and holding time (50-200ms) are automatically searched in the connector crimping process, which is 20 times more efficient than manual trial-and-error, increasing the yield rate from 91% to 99.3%.

2. Full-Process Closed Loop for Rapid Model Switching

Vision-Guided Calibration-Free Technology:

Deploy 3D structured light cameras (accuracy ±0.05mm) to scan new workpieces and automatically generate fixture compensation parameters (X/Y/Z offset ±0.1mm, angular deviation ±0.5°). A new energy vehicle factory achieves “zero manual calibration” model switching for 20 types of battery modules, reducing the time by 60%.

Automatic Mapping of Quality Data:

Each module integrates an RFID chip, which automatically associates with the corresponding quality inspection plan during model switching (e.g., Module A corresponds to ±0.1mm dimension detection, and Module B triggers ±5μm precision visual inspection). A German home appliance factory reduces model switching-related quality issues by 90%.

IV. In-Depth Industry Applications: Value Fission of Modular Design

1. Electronics Industry: Addressing Assembly Challenges of “Diverse Products”

- Case: Assembly of Apple AirPods Pro Headphones:

Through replaceable earstem positioning modules (compatible with 3 sizes) and adaptive pressing modules (pressure range 5-20N), the assembly tasks of left ear/right ear/charging case can be switched within 30 seconds. A single production line supports mixed production of 8 models, with 产能 3 times higher than traditional special machine lines.

2. Automotive Industry: Solving Manufacturing Dilemmas of “Multi-Platform Collinear Production”

- Technical Implementation: Battery Pack Assembly for Volkswagen MEB Platform:

Using extendable module handling modules (stroke 500-1500mm adjustable) and tightening modules compatible with different cell heights (Z-axis adaptive range ±10mm), mixed production of 8 battery models is achieved. The model switching time is compressed from 4 hours to 40 minutes, and equipment investment is reduced by 30%.

3. Medical Industry: Meeting “Stringent Compliance” Assembly Requirements

- Practice: Micro-Assembly of Medtronic Pacemakers:

Modular clean units (ISO 5 cleanliness) support rapid disassembly and sterilization (121℃ high temperature for 30 minutes). Combined with parameterized sterile process packages (e.g., welding time ≤0.2s to avoid protein denaturation), the switching time between different pacemaker models is shortened from 2 hours to 20 minutes, while meeting FDA process traceability requirements.

V. Future Trends: Intelligent Evolution of Modular Design

- Development of Self-Diagnostic Modules: Integrate vibration sensors (accuracy ±0.1g) and temperature sensors (resolution ±0.5℃) to achieve module-level fault prediction (8-hour advance warning of bearing wear with 95% accuracy).

- Application of Additive Manufacturing Modules: On-site 3D printing of customized fixtures (material PA12 nylon, strength ≥80MPa) shortens fixture preparation time from 24 hours to 2 hours, adapting to urgent prototyping needs.

- Digital Thread Integration: Through the ISO 23247 digital thread standard, full-process traceability of module design-manufacturing-operation is realized. A Swiss watch enterprise reduces module life cycle costs by 25% through this.

Conclusion

The essence of modular design is to decompose the manufacturing system into “definable minimum value units,” enabling production lines to acquire flexible genes of “responding to 万变 with invariance” through rapid recombination of physical modules and intelligent invocation of logical modules. When hardware has “plug-and-play” physical compatibility, software has “changing as needed” logical extensibility, and processes form “continuously precipitated” knowledge reusability, flexible equipment evolves from a single automation tool into a “manufacturing operating system” supporting enterprise strategies. In the future where product iteration is measured in hours, only manufacturing systems with modular genes can find the optimal solution in the paradox of “customized requirements” and “scale costs”—this is the ultimate value of modular design in reshaping manufacturing flexibility.