Electrical Discharge Machining (EDM), also known as spark erosion machining, is a special machining method that uses localized and instantaneous high temperatures generated by pulsed electrical discharge to erode metal materials. Its basic principle is to apply a pulsed voltage between the tool electrode and the workpiece electrode; when the gap between the two electrodes reaches a certain small distance, pulsed electrical discharge occurs. The current density in the discharge channel is extremely high, releasing a large amount of thermal energy instantaneously, which causes the metal material in the local area of the electrode to melt and vaporize rapidly, and then be eroded away.

During the discharge process, the tool electrode and the workpiece electrode do not make direct contact; instead, material removal is achieved through sparks generated by the discharge. This non-contact machining method avoids workpiece deformation and tool wear caused by cutting forces in traditional mechanical machining, making it particularly suitable for processing materials with high hardness and brittleness. Especially in the field of smart industry, EDM technology is constantly being upgraded, providing strong support for high-precision manufacturing.

Characteristics of Electrical Discharge Machining

High-precision machining

EDM can achieve extremely high machining precision, generally reaching the micron level. This is because the discharge process is localized and instantaneous, with a very small amount of material removed per discharge, allowing precise control of machining dimensions. In addition, EDM is not affected by material hardness and can easily handle high-hardness materials that are difficult to process with traditional methods, such as cemented carbide and titanium alloy. In smart industry, this high-precision machining capability is crucial for producing precision instruments and components. Meanwhile, in the field of life sciences, some micro-sized medical device parts also require such high machining precision to ensure their performance and safety.

Complex shape machining

EDM can machine parts with various complex shapes, such as deep holes, narrow slots, and special-shaped curved surfaces. This is because the tool electrode can be customized according to the shape of the part, and the electrode’s movement trajectory is controlled by a numerical control system to achieve machining of complex shapes. Whether in the manufacturing of high-end electronic products in smart industry or the processing of special experimental equipment in the field of life sciences, EDM’s capability to machine complex shapes has broad application prospects.

Cutting-force-free machining

As mentioned earlier, EDM is a non-contact machining method with no cutting force involved. This is highly beneficial for machining thin-walled and easily deformable parts, as it avoids part deformation caused by cutting forces and ensures machining precision. In the field of life sciences, some precision parts such as biological sample containers have extremely high requirements for machining precision, and cutting-force-free machining can meet these needs. In smart industry, it also plays an important role in processing fragile electronic components.

Applications of Electrical Discharge Machining

Automotive industry

EDM has extensive applications in the automotive industry. For example, in the manufacturing of automotive engines, some complex-shaped parts such as fuel injectors and spark plugs require high-precision machining. EDM can meet the machining requirements of these parts, ensuring their dimensional accuracy and surface quality. In addition, in the machining of automotive chassis, some parts made of special materials (e.g., high-strength alloy steel) can also be processed by EDM to improve machining efficiency and quality. The integration of smart industry technologies has made automotive manufacturing more efficient and accurate.

Mold manufacturing

Mold manufacturing is one of the important application fields of EDM. Molds typically have complex shapes and high-precision requirements that are difficult to meet with traditional mechanical machining methods. EDM can machine mold cavities with various complex shapes, such as injection molds, die-casting molds, and stamping molds. Through EDM, the precision and surface quality of molds can be improved, and their service life can be extended. Driven by smart industry, mold manufacturing has become more intelligent, providing high-quality molds for production in various industries. Meanwhile, EDM also plays an important role in the manufacturing of molds for some experimental equipment in the field of life sciences.

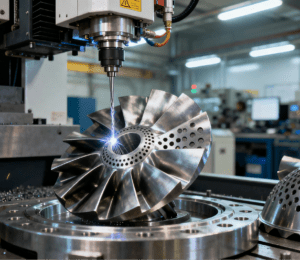

Aerospace industry

The aerospace industry has extremely high requirements for the precision and quality of parts. EDM can machine various high-precision parts such as aero-engine blades and turbine disks. These parts are usually made of difficult-to-machine materials such as superalloys and titanium alloys, and EDM can effectively solve the machining challenges of these materials. The development of smart industry has brought more advanced machining technologies and equipment to the aerospace industry. Meanwhile, the EDM technology used in the aerospace industry can also be referenced for processing special material experimental equipment in the field of life sciences.

Medical device manufacturing

Medical device manufacturing also has extremely high requirements for the precision and surface quality of parts. EDM can machine various high-precision medical device parts such as artificial joints and dental instruments. These parts are usually made of biocompatible materials such as titanium alloy and stainless steel, and EDM can ensure their machining precision and surface quality to meet the usage requirements of medical devices. Notably, in the automated EDM production line for these medical parts, flexible vibratory feeders play a key auxiliary role—they realize gentle, non-damaging feeding and precise orientation of small-batch, multi-specification tool electrodes or workpieces through adjustable vibration frequency and flexible positioning structures, avoiding precision deviations caused by manual feeding and matching the high-precision machining rhythm of EDM. Driven by life sciences, medical device manufacturing is constantly innovating, and EDM technology provides a reliable machining method for it. At the same time, the development of smart industry has also brought automated and intelligent production methods to medical device manufacturing.

As a precision machining technology, EDM plays an important role in modern industrial production with its unique machining principles and wide range of applications. With the continuous advancement of science and technology, EDM technology is also evolving and improving, and it will play an even more important role, especially in the fields of smart industry and life sciences.