Amid the transformation of the manufacturing industry toward “high precision, high customization, and high efficiency,” the selection of high-quality component manufacturers directly affects the product quality and production efficiency of downstream enterprises. As a professional component manufacturer with years of experience in the industry, Airey Precision Machinery relies on the mature resources and technical strength of Dongguan CNC processing plants to provide “high-precision, short-delivery, and fully customized” component processing services for fields such as automotive, electronics, medical care, and automation equipment. It has become a stable cooperative component supply partner for many enterprises.

Prominent Pain Points in Manufacturing Component Processing: Professional Component Manufacturers as the Key to Breaking the Dilemma

Downstream enterprises often face three core pain points in the process of component procurement and processing. These issues not only increase production costs but also may delay production schedules:

Substandard precision and poor adaptability: Ordinary processing methods struggle to meet the component tolerance requirements of precision equipment (e.g., ±0.005mm), leading to gaps and jams during component assembly, which affects product performance.

Unstable delivery schedules and slow response: Some small workshop-style processing plants lack standardized production processes, and delays are prone to occur when orders pile up. Downstream enterprises are forced to suspend production due to component shortages.

Weak customization capabilities and poor demand matching: Faced with non-standard components (e.g., special-shaped structures, special materials), most processing plants cannot quickly formulate processing plans or achieve the full-process connection of “design – prototyping – mass production.”

As a manufacturer focusing on precision components, Airey Precision Machinery fundamentally solves these pain points by virtue of the standardized system and technical accumulation of Dongguan CNC processing plants, providing customers with component processing services characterized by “guaranteed precision, predictable delivery, and implementable customization.”

Airey Precision Machinery: Core Advantages of Dongguan CNC Processing Plants Support Professional Component Manufacturing

As a component manufacturer rooted in Dongguan, Airey Precision Machinery’s core competitiveness stems from the three-in-one support of “hardware equipment + technical team + process control.” The mature configuration of Dongguan CNC processing plants serves as the foundation for its high-precision processing.

Hardware of Dongguan CNC Processing Plants: High-Precision Equipment Lays the Foundation for Quality

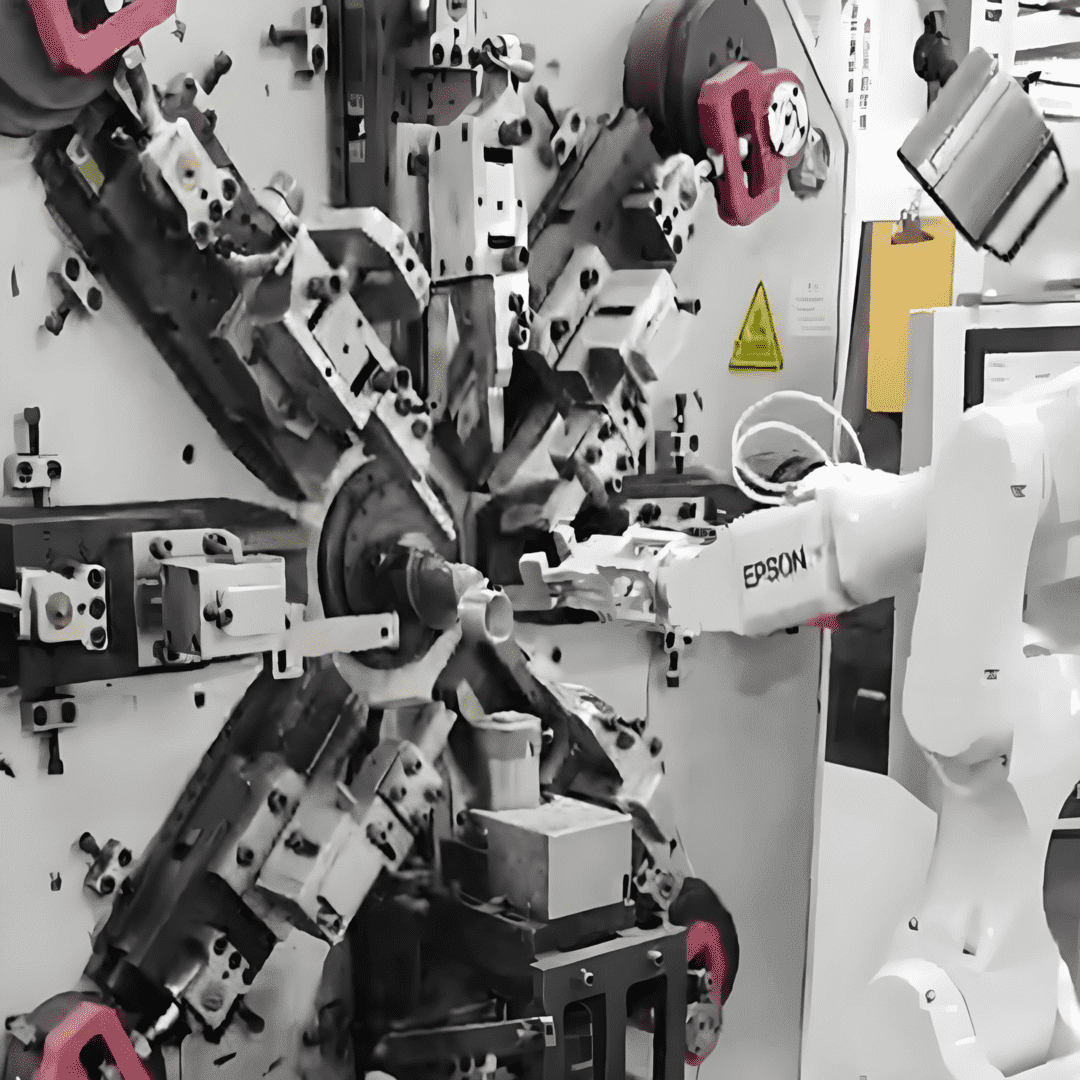

Airey Precision Machinery’s Dongguan CNC processing plant is equipped with a full set of advanced processing equipment, covering the entire process needs from rough processing to precision processing, ensuring component precision and efficiency:

Multi-model CNC machining centers: It has more than 20 vertical and horizontal CNC machining centers, supporting the processing of various materials such as aluminum alloy, stainless steel, titanium alloy, and engineering plastics. The minimum processing tolerance can reach ±0.002mm, meeting the high-precision requirements of precision components.

Complete supporting auxiliary equipment: Equipped with CNC lathes, grinders, wire-cutting machines, and coordinate measuring machines, it realizes the integration of “processing – inspection – correction,” avoiding precision deviations caused by lack of equipment.

Automated production configuration: Some production lines have introduced automatic loading and unloading devices, increasing the daily processing efficiency of a single CNC equipment by 30% and shortening the delivery cycle of bulk orders.

Technology and Services of the Component Manufacturer: Core Value Beyond Traditional Dongguan CNC Processing Plants

Airey Precision Machinery is more than a traditional Dongguan CNC processing plant; it is a professional component manufacturer that “understands needs, can customize, and values services.” Its core advantages are reflected in two major dimensions:

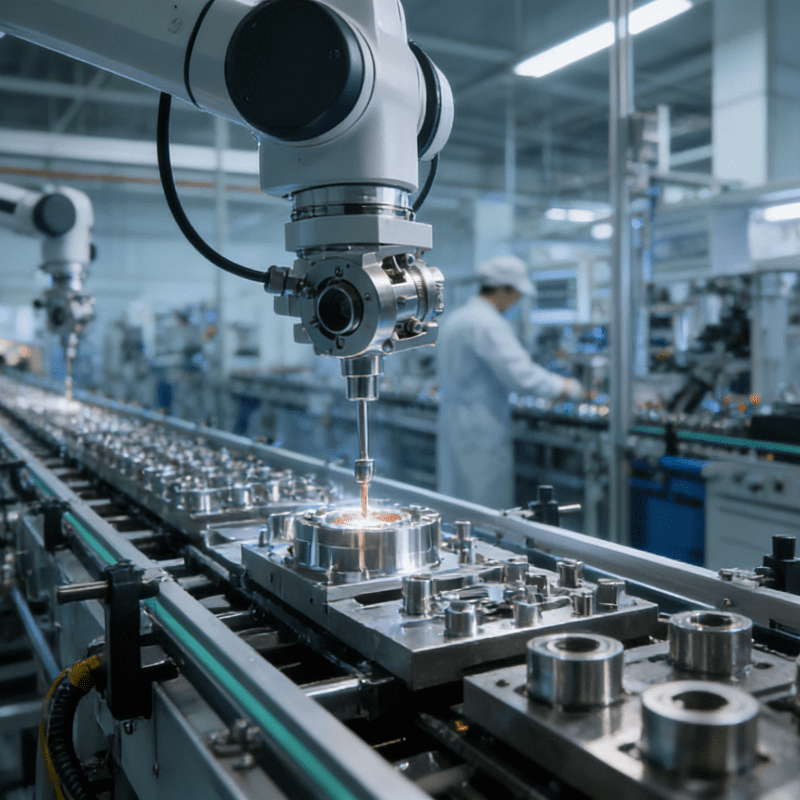

Full-process customization capability: Starting from customer demand communication, it provides a full-chain service including “design optimization – process planning – prototype sampling – mass production – after-sales tracking.” For example, for medical equipment components such as nebulizer mask assembly parts, it optimizes the CNC processing path based on material characteristics (e.g., medical-grade soft silicone matching, corrosion-resistant stainless steel fasteners) to ensure components meet medical industry biocompatibility and airtightness standards.

Rapid response and short delivery: Relying on the supply chain advantages of Dongguan’s manufacturing cluster (e.g., local material procurement, supporting heat treatment services) and a standardized production scheduling system, it can achieve “3-day prototyping and 7-day mass production” for conventional precision component orders, and start processing emergency orders within 24 hours.

Strict quality control: It has established a three-level quality inspection system covering raw material warehousing (material inspection), processing process (first-piece inspection + patrol inspection), and finished product delivery (full-size inspection). Inspection reports are provided for each batch of components to ensure a delivery pass rate of over 99.9%.

Multi-Field Application: Application Scenarios of Airey Precision Machinery’s Component Manufacturing

With the technical strength and customized services of Dongguan CNC processing plants, Airey Precision Machinery’s component products have been widely used in three core fields, addressing component needs in different industries:

Automotive component field: It provides CNC processing services for automotive electronics (e.g., sensor housings) and chassis systems (e.g., precision connectors). The component materials are mainly aluminum alloy and high-strength steel, meeting the automotive industry’s requirements for impact resistance and high precision.

Electronic equipment field: It processes communication equipment (e.g., 5G base station components) and consumer electronics (e.g., core components of drones). Relying on high-precision CNC equipment, it realizes one-time forming of complex structures, reducing component assembly errors.

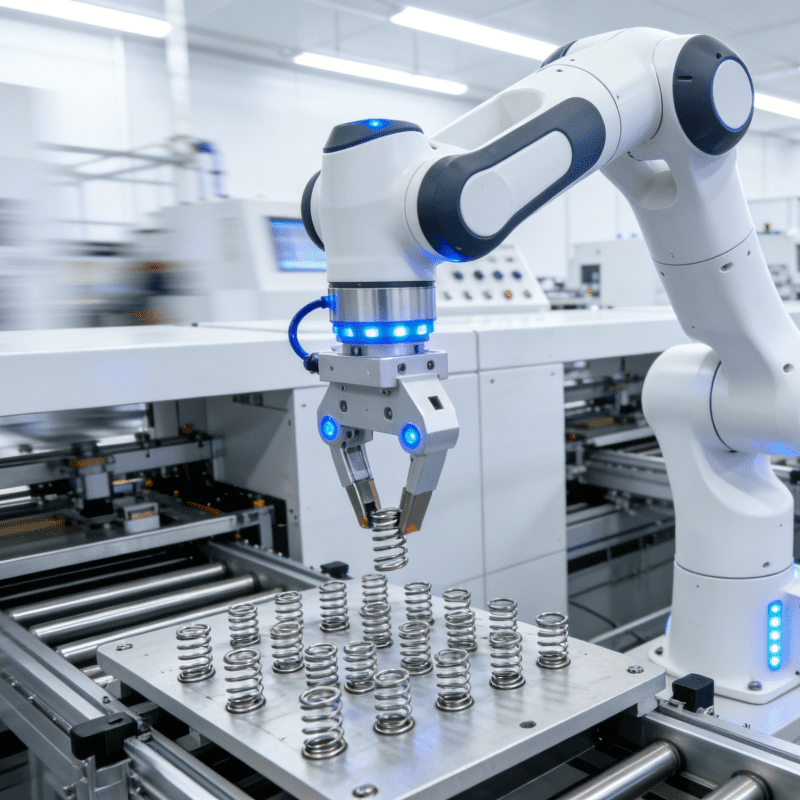

Automation and medical field: It provides customized processing for automation equipment (e.g., robotic arm joint components) and medical instruments—including key components for nebulizer mask assembly (such as precision valve seats, air duct connectors, and sealed gaskets). It strictly complies with ISO 13485 medical device quality management system standards, ensuring the airtightness, biocompatibility, and assembly accuracy of components to support the safe and stable operation of nebulizer products.

Choose a Professional Component Manufacturer: Recognize Airey Precision Machinery’s Dongguan CNC Processing Strength

In today’s increasingly competitive manufacturing industry, “component quality” is the foundation of an enterprise’s product competitiveness, and choosing a reliable component manufacturer is the key first step. As a manufacturer with both “the hardware strength of Dongguan CNC processing plants” and “professional component customization services,” Airey Precision Machinery not only solves the problems of “insufficient precision and unstable delivery” of ordinary processing plants but also fills the gaps of “low customization flexibility and slow response” of large manufacturers.

·

Whether it is production enterprises in need of bulk precision components or R&D teams with non-standard component customization needs—including those requiring high-precision parts for nebulizer mask assembly—Airey Precision Machinery can provide cost-effective component solutions with its mature CNC processing system and full-process services.