As the home appliance industry accelerates towards high efficiency, precision, and intelligence, the comprehensive improvement of production takt has become an industry consensus. Customers are imposing more stringent requirements on the supply chain’s response speed, delivery efficiency, and product precision. The limitations of traditional presses in precision control, flexible adaptation, energy conservation and consumption reduction are becoming increasingly prominent. Meanwhile, servo presses, relying on their core technological advantages, are gradually emerging as the mainstream equipment in the home appliance manufacturing sector, leading the innovation of industry production models.

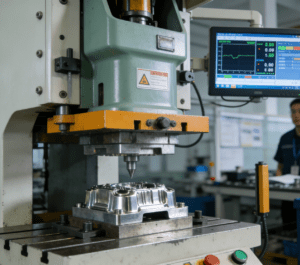

Founded in 2010, Wuxi Aidu Technology has focused on the production of white goods equipment and mold manufacturing for more than a decade, providing R&D and production services for core components to global kitchen appliance brands. Driven by technological innovation, the company continuously explores new application scenarios such as smart home appliances and professional equipment, and is committed to becoming a core enabler in the global precision manufacturing industry chain. After multiple rounds of inspections and research, Aidu ultimately selected the SME2-1000T high-precision servo press.

Yawei’s servo press has innovatively developed core technologies including servo control system, servo-specific motor, direct-drive transmission, and AFE energy feedback system, leading the technological development of servo presses. It features the following advantages:

– High-efficiency and high-precision direct-drive transmission design for precise backlash-free transmission, ensuring accurate and controllable stamping movements every time

– Equipped with low-speed and high-torque motor technology, fully covering the application needs of the entire series of servo presses with stable and powerful power output

– Adopting full closed-loop servo control technology, the slide block enables stepless speed regulation and precise operation, adapting to diverse process scenarios

– Highlighted by the advantage of multi-functionality in one machine, it can be flexibly configured with 12 stamping curves to easily meet the requirements of various complex stamping conditions

– Equipped with an EtherCAT high-speed bus communication system to achieve microsecond-level response, greatly improving production takt

– Innovatively integrated with energy recovery and feedback technology, effectively reducing enterprises’ dependence on the power grid and supporting green production

– Visual presentation of forming parameters for transparent and controllable production processes, facilitating process optimization and quality traceability

– With bottom dead center position detection and compensation functions to further improve stamping precision and product consistency

– Supporting stamping process simulation, analysis and optimization to realize free-form stamping control, reducing mold trial costs and time

– Equipped with intelligent communication interfaces for seamless integration into smart factory production systems, helping enterprises achieve digital transformation

Since the commissioning of Yawei’s 1000T servo press, Aidu Technology has seen a significant improvement in production efficiency and mold trial results. Before mold delivery, Aidu Technology can rely on this equipment to accurately replicate the actual equipment operating status and process parameters used by customers, and conduct closed-loop testing on key parameters of the servo press such as tonnage, stroke speed, and stamping curve. By simulating the actual operating environment of the client side, multiple rounds of mold trials and process verification are completed to ensure that the molds are in a “ready state” upon delivery, greatly shortening the customer’s production launch cycle. Today, relying on its lean and efficient production capacity, Aidu Technology has successfully established stable cooperative relationships with major home appliance enterprises such as Midea Group, Panasonic Appliances, and Hisense Group, gaining a favorable position in market competition. This achievement not only demonstrates Aidu Technology’s strength in the industry, but also confirms the excellent quality and reliable performance of Yawei’s servo presses.

In the home appliance industry, Yawei’s servo press focuses on the core needs of precision sheet metal processing, and is widely adapted to the production of key components for refrigerators, air conditioners, washing machines, small home appliances and other products, achieving dual optimization of efficiency and precision, and injecting strong impetus into the high-quality development of home appliance manufacturing enterprises.

Core Application Scenarios

Home appliance shell/panel processing: For components such as refrigerator side panels, air conditioner outdoor unit shells, and washing machine inner tub flanges, it completes processes like punching, bending, and blanking. With high-precision control, it ensures product dimensional consistency, and achieves damage-free surface processing to improve product appearance quality.

Functional component production: Adapted to multi-station continuous stamping of products such as air conditioner heat exchanger fins (micro-hole stamping with aperture ≤ 1mm), washing machine balance rings, and small home appliance brackets, meeting mass production needs and ensuring production efficiency and product stability. Notably, Yawei’s servo press can be seamlessly connected with nut automatic assembly machines in this scenario — after completing the precision stamping of small home appliance brackets and washing machine balance ring substrates, the workpieces are directly transferred to the nut automatic assembly machine for automated and high-precision nut press-fitting. The servo press’s high-precision position control provides a stable foundation for the subsequent assembly process, ensuring the coaxiality and assembly firmness of nuts, while the integrated production line formed by the two devices further shortens the production takt and reduces manual intervention errors.

Precision structural component manufacturing: For precision components such as relay shrapnel, home appliance switch contacts, and radiator heat dissipation holes, it achieves high-precision stamping, adapting to the development trend of miniaturization and thinness of home appliance products, and helping enterprises build core competitiveness.

Core Advantages

Controllable precision: Repeat positioning accuracy reaches ±0.01mm, accurately solving the assembly gap problem of home appliance parts, improving product assembly precision and user experience, and reducing after-sales risks.

Flexible production: Stroke and speed can be adjusted steplessly, easily adapting to different thicknesses of plates such as 0.1-3mm cold-rolled plates and aluminum plates. No need to adjust mechanical parameters during mold switching, greatly shortening production line changeover time and improving the flexible adaptation capability of the production line.

Better working conditions: For 6-20mm medium and thick plate materials, it realizes silent blanking, effectively avoiding on-site noise pollution and improving the production environment. The servo control + mechanical transmission mode completely solves the on-site oil pollution problem caused by stretched workpieces in traditional processing modes, helping enterprises build green and clean factories.

High efficiency and energy saving: Progressive die stamping can adopt the pendulum mode, increasing production capacity by more than 50% and significantly improving enterprise production efficiency. Compared with traditional mechanical presses, it saves 30%-50% of electricity, greatly reducing enterprise production costs and enhancing market competitiveness.

Empowering precision manufacturing and exploring new industry prospects together. Yawei’s servo press sincerely invites more home appliance manufacturing enterprises to cooperate hand in hand, drive industrial upgrading with advanced technology, achieve customer value with excellent quality, and win-win future development.

robotic trimming system

industrial robotic arm for sale