As a crucial milestone in modern manufacturing, 5-axis machining technology has brought revolutionary changes to the production of complex components with its outstanding performance and versatile machining capabilities. By adding two rotary axes to traditional 3-axis machine tools, this technology greatly expands the machining range, improves processing efficiency, and ensures higher machining precision.

Capability to Machine Complex Components

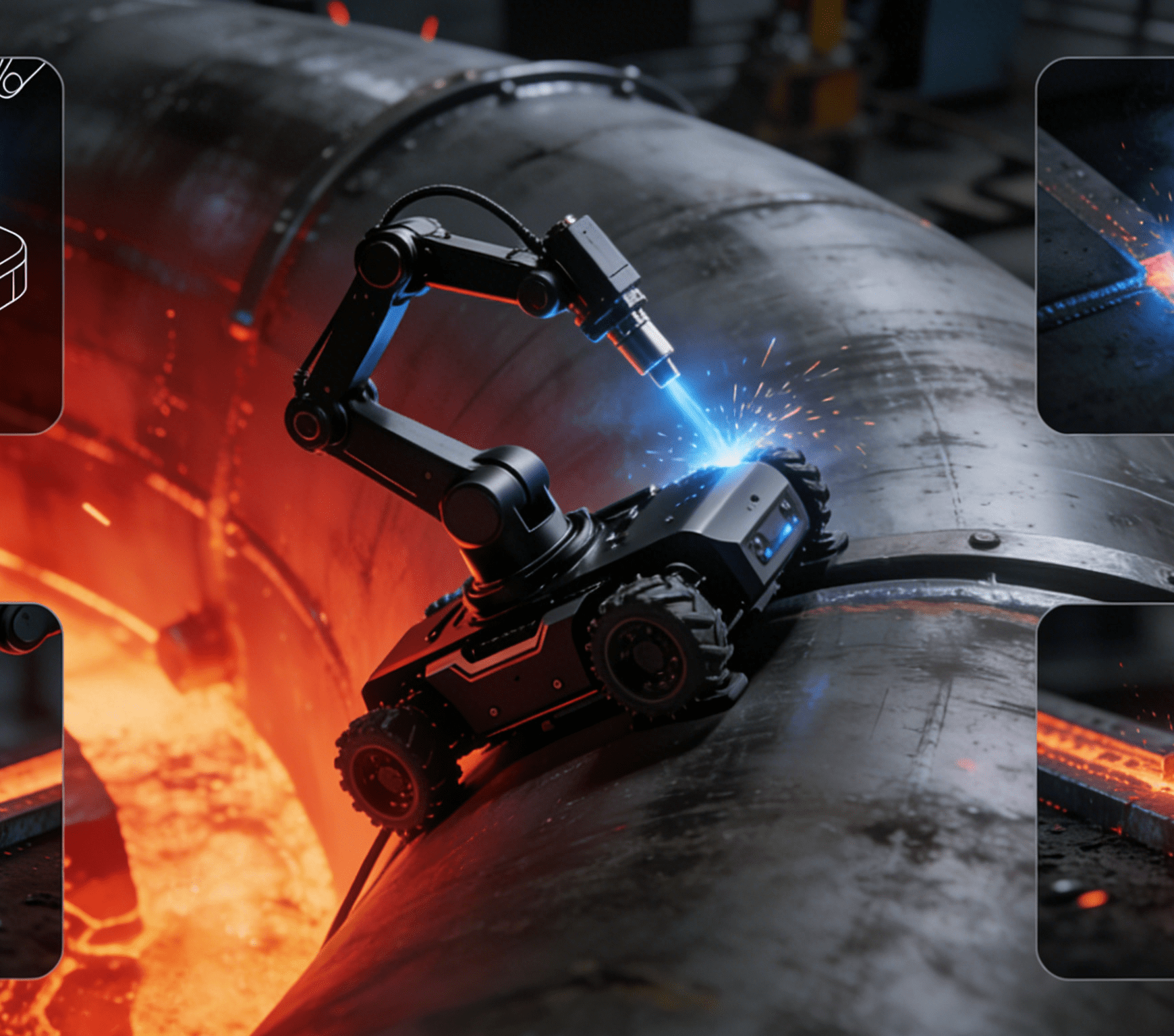

One of the core advantages of 5-axis machining is its ability to handle complex geometric structures. Compared with traditional 3-axis machining, 5-axis machining can more easily access every surface of the workpiece, including those that are otherwise unreachable. This is particularly important for complex components commonly used in industries such as aerospace, automotive manufacturing, and mold making. 5-axis machine tools can accurately position the angle between the cutting tool and the workpiece, enabling efficient machining of complex surfaces and inclined planes.

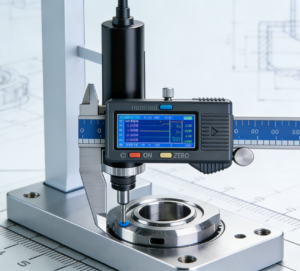

Improved Production Efficiency and Precision

5-axis machining significantly boosts production efficiency by reducing the frequency of workpiece clamping and tool changes. Meanwhile, since it can machine multiple surfaces in a single setup, the production cycle is greatly shortened. When paired with a Robotic Small Product Tray Loading System, the automated workflow is further optimized: after 5-axis machining completes high-precision processing of small complex parts (such as micro-components for medical devices or precision automotive parts), the robotic system immediately performs intelligent sorting, positioning, and tray loading without manual intervention. This integration not only eliminates the bottleneck of manual handling and sorting, but also avoids surface scratches or precision deviations caused by human contact, ensuring consistent part quality while increasing overall production throughput by 30% or more. In addition, the high-precision control and multi-axis synchronization technology of 5-axis machining ensure high accuracy during the machining process, especially when processing complex shapes.

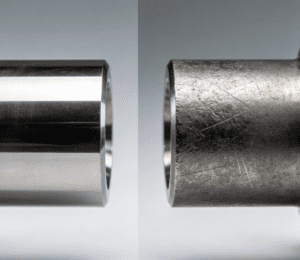

Better Material Utilization and Cost Savings

5-axis machining enables more efficient utilization of raw materials and reduces material waste. It allows for longer tool overhangs, enabling the cutting tool to penetrate deeper into the material and thus machine more components. This is particularly vital for processing expensive materials such as titanium alloys and stainless steel.

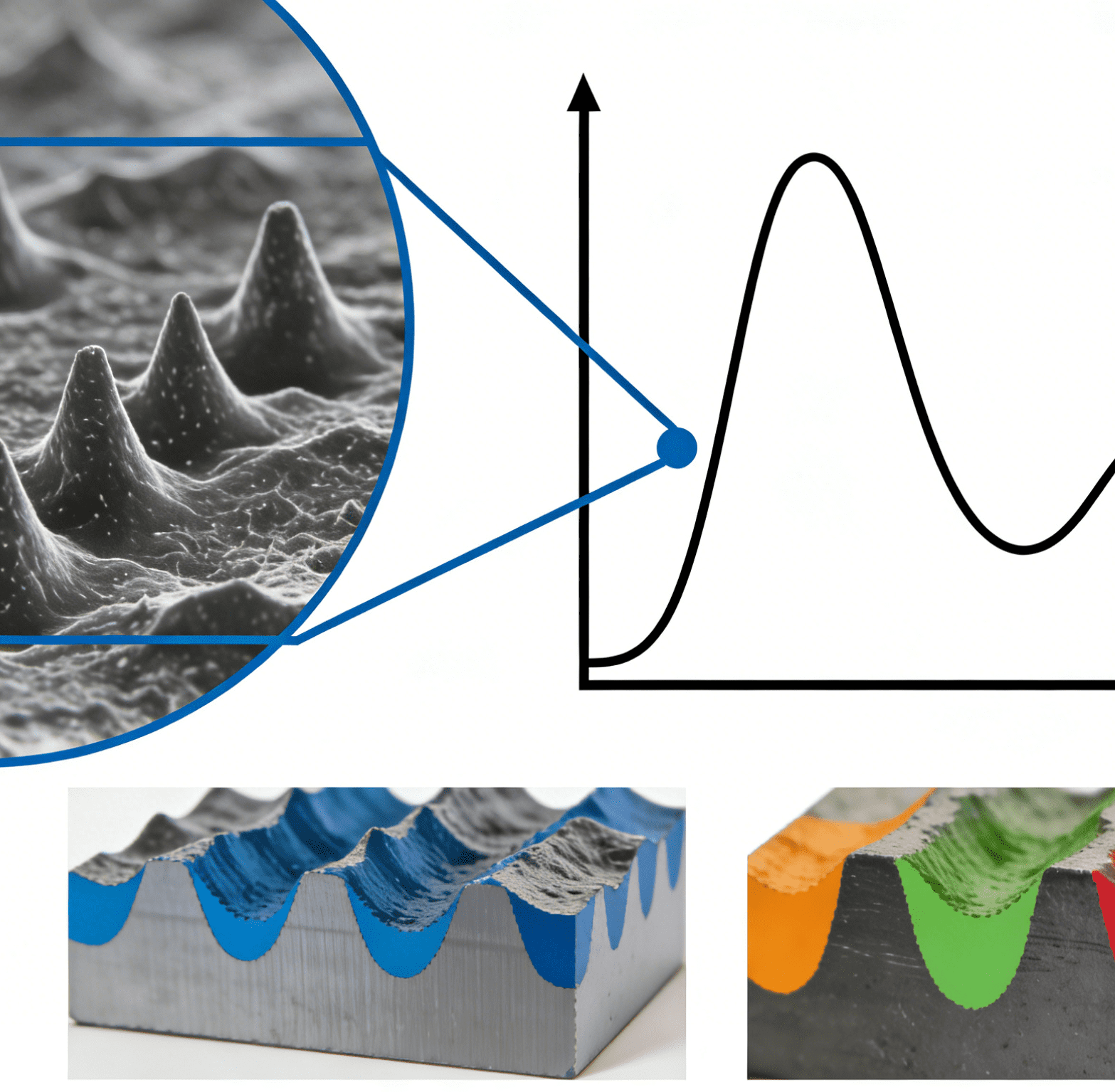

Enhanced Surface Machining Quality

Thanks to its unique machining method, 5-axis machining can maintain optimal contact between the cutting tool and the workpiece surface, resulting in superior surface finishing effects. This machining method reduces subsequent processes such as manual grinding and trimming, saving both time and costs.

Ares Precision adopts 5-axis machining centers, which significantly improve machining efficiency and precision. By reducing the frequency of workpiece clamping and tool changes, the company meets customer demands with shorter production cycles and provides high-quality components for industries with stringent high-precision requirements.