As important equipment in the field of modern precision manufacturing, 4-axis simultaneous CNC machine tools possess unique advantages and application potential. When we gain an in-depth understanding of CNC machine tools, the definition of 4-axis simultaneous machining is that a fourth axis, namely the rotary axis, is added on the basis of traditional 3-axis machining. This enables not only planar cutting during the machining process but also three-dimensional processing of complex parts, thus greatly improving machining flexibility. In addition, 4-axis machine tools can achieve multi-angle and multi-directional machining on a fixed workpiece, thereby enhancing production efficiency and part precision. Notably, for batch production of small precision parts, 4-axis simultaneous CNC machine tools can be seamlessly connected with Robotic Small Product Tray Loading System, forming a “precision machining – automatic loading” continuous workflow that significantly reduces manual intervention.

We can understand its working principle as the axis components that are independent of each other but work closely in coordination. Compared with ordinary 3-axis machine tools, the mechanical arm can move not only in the X, Y, and Z directions but also function in the rotational direction. As a result, the ability to machine complex curved surfaces or special-shaped parts is significantly improved. Furthermore, 4-axis simultaneous CNC machine tools can realize automatic tool changing, which enhances the continuity and efficiency of the production process. When matched with Robotic Small Product Tray Loading System, the processed small parts can be automatically sorted, positioned and loaded into trays according to preset parameters, avoiding precision loss caused by manual handling and further improving the consistency of the production process. In this era where intelligent manufacturing is increasingly becoming a trend, the combination of 4-axis simultaneous CNC machine tools and such automated loading systems is undoubtedly an important foundation for exploring the field of precision manufacturing.

Working Principle and Structure of 4-Axis Simultaneous CNC Machine Tools

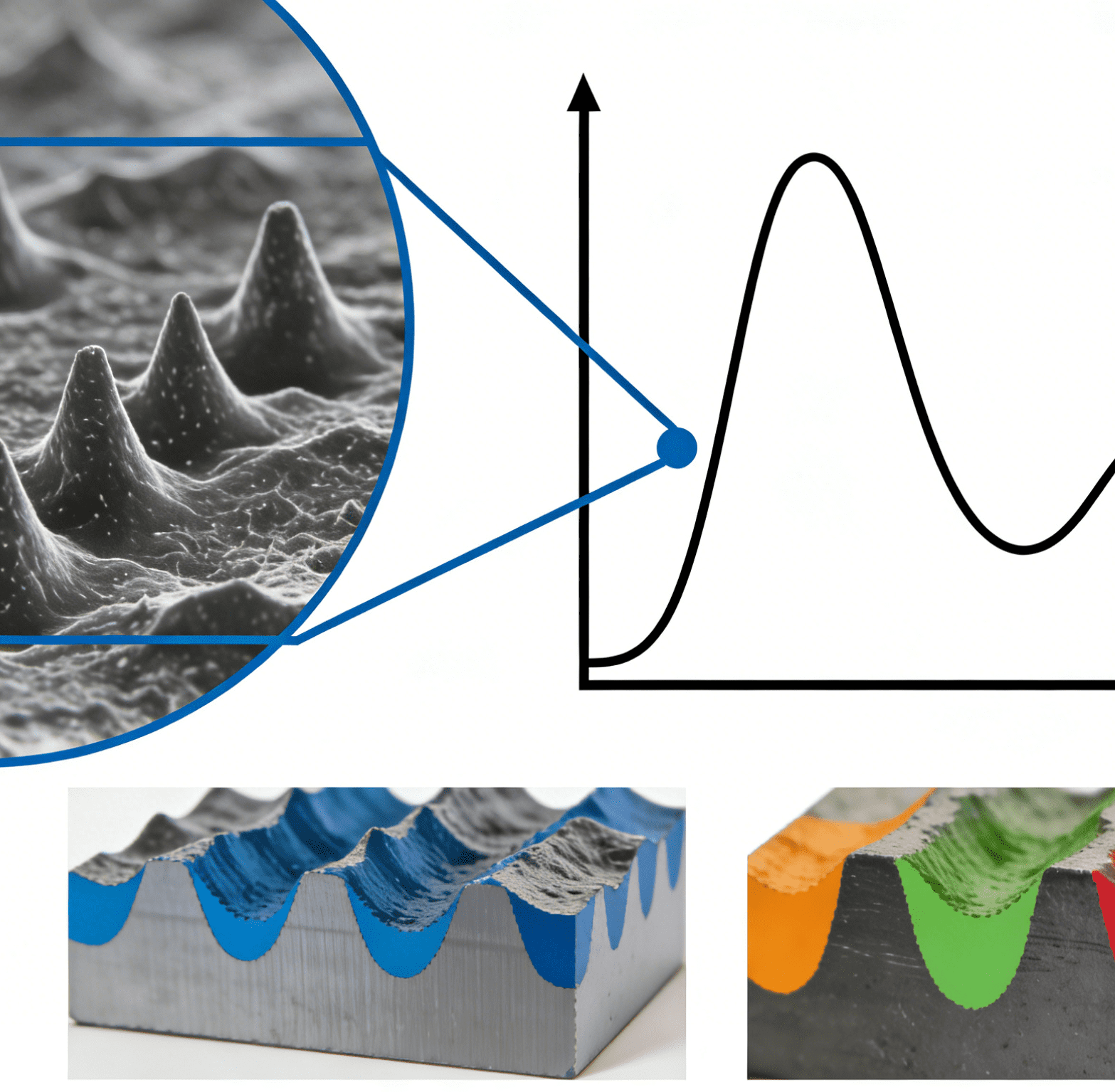

In 4-axis simultaneous CNC machine tools, the composition of the equipment is the foundation of its precision machining function. Such machine tools usually consist of a spindle, worktable, tool magazine, servo drive system, and control system, among other components. The spindle is responsible for rotating the cutting tool to perform cutting, while the worktable carries the machining material and can move in multiple directions, enabling the efficient manufacturing of parts with complex shapes. It should be noted that the synergistic effect of the four axes allows the machine tool to achieve precise positioning and cutting in three-dimensional space. This multi-dimensional movement mode greatly improves the flexibility in the machining process, making us handle complex workpieces with ease. For small parts that require high-precision batch processing, the stable machining accuracy of 4-axis machines provides a reliable premise for the subsequent automatic loading of Robotic Small Product Tray Loading System, ensuring that the parts can be accurately identified and placed by the robot.

Specifically, the various axes are precisely controlled and coordinated through the CNC system, realizing multi-surface machining of parts with complex shapes in a single clamping. This not only improves machining accuracy but also reduces errors caused by repeated clamping. This design enables us to minimize material waste during the cutting process while improving production efficiency. In addition, the simultaneous movement of each axis allows us to quickly switch between different processes, reducing the production cycle. Moreover, this high-efficiency processing capability provides more possibilities for precision manufacturing. When integrated with Robotic Small Product Tray Loading System, the entire production line can realize unmanned operation from raw material processing to finished product loading, making 4-axis simultaneous CNC machine tools an indispensable core component in modern intelligent manufacturing lines.

Application Cases of 4-Axis Simultaneous CNC Machine Tools in Precision Manufacturing

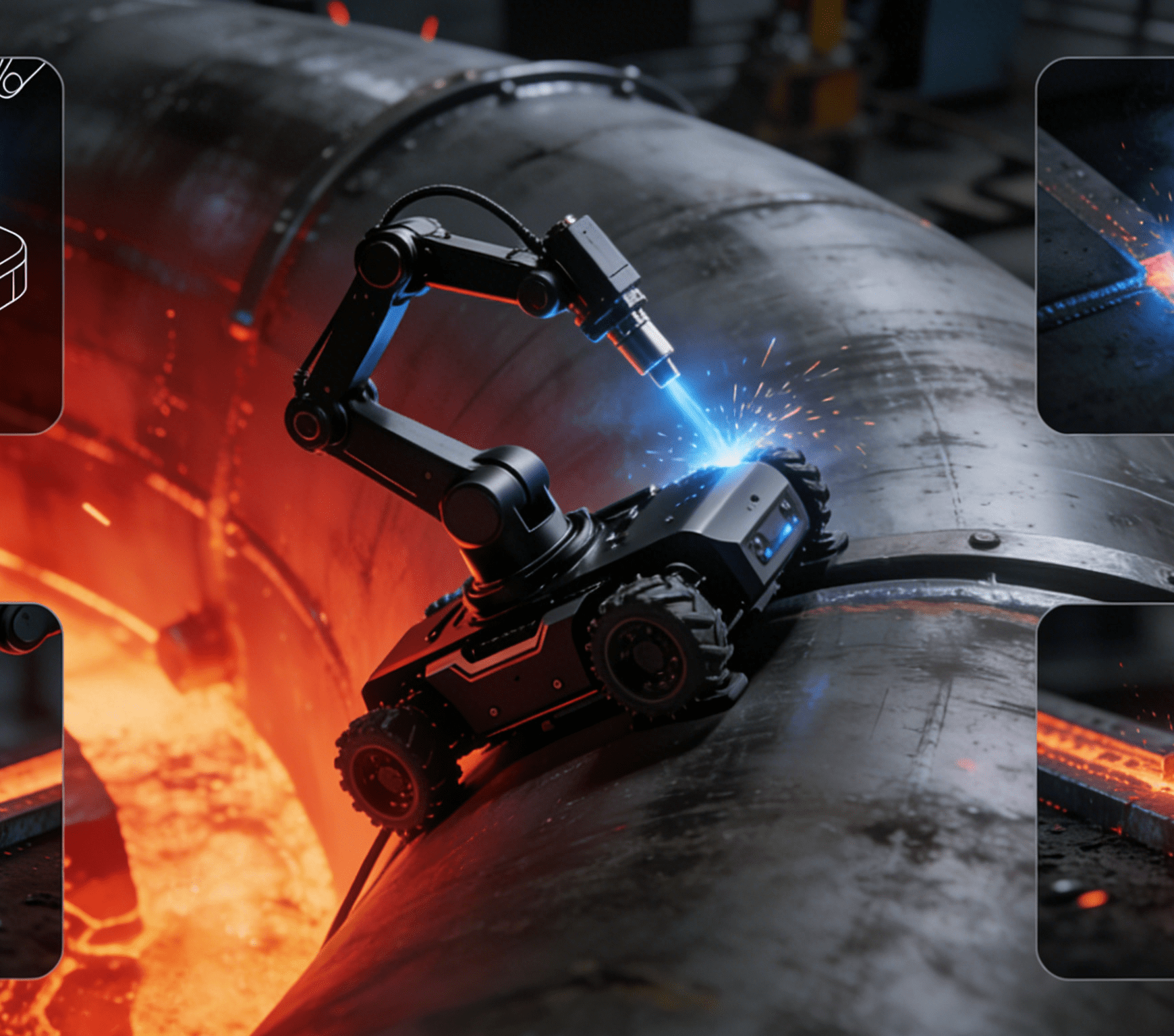

When discussing the practical applications of 4-axis simultaneous CNC machine tools, we can see their extensive use in the field of precision manufacturing. One typical case is the manufacturing of components in the aerospace industry. In this industry, the complex shapes and high-precision requirements of parts make traditional CNC machine tools incompetent. However, 4-axis simultaneous CNC machine tools, with their efficient multi-axis machining capability, can complete multi-angle machining in a single clamping, greatly improving machining efficiency and reducing errors. Another noteworthy example is medical device manufacturing. In this field, 4-axis simultaneous CNC machine tools can not only ensure the dimensional accuracy of products but also meet the strict requirements for surface finish and complex structures. We have also found that in the automotive industry, the production of specific components such as engine connecting rods also applies 4-axis simultaneous technology.

A more representative integrated application is reflected in the batch production of automotive precision small parts (such as valve cores, sensor housings) and medical micro-components. After 4-axis simultaneous CNC machine tools complete high-precision machining of these small parts, the Robotic Small Product Tray Loading System immediately takes over the subsequent process. Equipped with vision recognition and precision positioning modules, the system can automatically distinguish parts of different specifications, adjust the clamping force according to the material characteristics, and accurately place them into standard trays with consistent spacing. This integration not only avoids scratches and precision damage caused by manual handling but also ensures that the output rhythm of the machine tool matches the loading speed, making the daily output of small parts increase by about 20% compared with the manual loading mode. These cases demonstrate the important role of 4-axis simultaneous CNC machine tools (and their collaborative automated equipment) in improving production efficiency and meeting the processing requirements of complex parts. Through practice, we are more convinced of the advantages and prospects of this integrated application in precision manufacturing.

Comparative Analysis with Other CNC Machine Tools

When compared with other types of CNC machine tools, the advantages of 4-axis simultaneous CNC machine tools become more prominent. First of all, traditional 3-axis CNC machine tools are often limited by space and time when processing complex parts because they can only operate in the X, Y, and Z directions. This limitation often leads to low production efficiency, while 4-axis simultaneous machine tools can process workpieces at any angle by adding a rotary axis, greatly improving machining flexibility and efficiency. We can observe from practical cases that when using 4-axis simultaneous machine tools, the time required to process complex curved surfaces or cavities is significantly less than that when using 3-axis machine tools.

At the same time, compared with 5-axis machine tools, 4-axis simultaneous CNC machine tools have a higher cost performance ratio. Although 5-axis machine tools have stronger machining capabilities, their investment and maintenance costs are relatively higher. In many industries, we find that 4-axis machine tools can meet most precision machining needs, enabling enterprises to maintain cost control. When matched with cost-effective Robotic Small Product Tray Loading System, the overall investment of the production line is more controllable than that of 5-axis machine tool production lines, which is more in line with the cost-saving needs of small and medium-sized enterprises for precision manufacturing.

In addition, considering the complexity of programming and operation, 4-axis simultaneous CNC machine tools usually have a user-friendly operation interface, allowing our technical personnel to get started and implement production more quickly. This also reduces training costs to a certain extent and improves overall work efficiency. The programming logic of Robotic Small Product Tray Loading System can also be docked with the CNC system of 4-axis machines, realizing unified parameter setting and process monitoring, further reducing the difficulty of operation and management. Therefore, we believe that when selecting suitable CNC equipment, 4-axis simultaneous CNC machine tools, together with supporting automated loading systems, are a priority option worthy of consideration due to their unique advantages.

Reasons for Choosing 4-Axis Simultaneous CNC Machine Tools and Future Outlook

When we choose 4-axis simultaneous CNC machine tools, we mainly consider their unique advantages in precision manufacturing. First of all, the structural design of the machine tool enables each axis to work collaboratively, improving machining efficiency. Especially in the processing of complex parts, it can achieve multi-angle and multi-directional coordination, which not only shortens the processing time but also reduces the number of workpiece clamping times, thereby improving production efficiency. In addition, 4-axis machine tools perform excellently in improving machining accuracy, and fine adjustments among various processes make our products more competitive in the market. The compatibility with Robotic Small Product Tray Loading System further amplifies these advantages by realizing the automation of the whole process from machining to finished product storage.

Looking to the future, with the development of intelligent manufacturing, 4-axis simultaneous CNC machine tools will be increasingly integrated into automated production lines, and the combination with Robotic Small Product Tray Loading System, intelligent sorting equipment and MES systems will form a more intelligent and efficient production mode. We can expect that through the data interconnection between the two, the loading system can predict the output of parts according to the machining progress of the 4-axis machine tool, and pre-adjust the tray position and loading rhythm to realize “predictive loading”. We believe that through continuous optimization and upgrading of such integrated applications, 4-axis simultaneous CNC machine tools will play a more important role in the precision manufacturing industry, thereby driving the entire industry to a higher level. Therefore, in terms of investment, we are more inclined to choose 4-axis simultaneous CNC machine tools with advanced technology and stable performance, and match them with suitable Robotic Small Product Tray Loading System to cope with the challenges brought by the ever-changing market.