Table of Contents

ToggleAccelerating Manufacturing Innovation through Automated Assembly Design

In the ever-evolving landscape of modern manufacturing, a seismic shift is underway, driven not only by the surging demand for artificial intelligence servers but also by the need to revolutionize the production of diverse goods, from high-tech electronics to essential household items like sanitary ware and bathroom fixtures. The production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, for instance, faces its own set of challenges in an increasingly competitive market, where efficiency, precision, and innovation are key. This digital revolution isn’t just about creating more powerful hardware; it’s a full-scale reimagining of how high-performance systems and specialized manufacturing equipment are designed and assembled. As the need for cutting-edge technology grows exponentially across various sectors, manufacturers find themselves at a crossroads, compelled to abandon traditional methods and embrace transformative approaches.

At the forefront of this change is virtual simulation technology, a game-changing tool that acts as a bridge between the abstract world of design and the tangible realm of production. Whether it’s streamlining the assembly of AI servers or optimizing the manufacturing process of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, this technology enables manufacturers to simulate the entire assembly process before a single physical prototype is built. By doing so, it’s rewriting the rules of efficiency, eliminating costly delays, and unlocking new levels of innovation that were once thought out of reach. The booming development of artificial intelligence servers is indeed driving manufacturers to transform the way they design and build high-performance hardware systems. However, the same principles of virtual simulation and automated assembly design can be equally transformative for the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where precision in assembly and optimization of the manufacturing process are crucial for delivering high-quality products.

Leading this transformation are the advancements in virtual simulation technology, which bridge the gap between design and manufacturing. By simulating the assembly process before building physical prototypes, manufacturers can identify and address issues early on, thus avoiding costly delays caused by problems discovered on the shop floor. This is just as relevant for the complex assembly of AI servers as it is for the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where a single design flaw or assembly issue can lead to significant production setbacks and increased costs. The traditional approach to server design based on CPUs and GPUs involves multiple physical iterations, and stakeholders need to review the prototypes after the prototyping is completed. However, product simulation before assembly can optimize these prototype cycles by virtually validating the assembly process. Similarly, in the design of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, incorporating virtual simulation can significantly reduce the number of physical prototypes needed, saving time and resources.

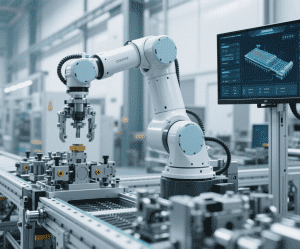

Incorporating the principles of Design for Automated Assembly (DFAA) can play multiple roles in the manufacturing process. In addition to evaluating robotic assembly designs, DFAA can help teams determine whether their existing automation capabilities can handle design tolerances, while also enabling early automation planning and maximizing the automation of the design. This approach is not only beneficial for the high-tech manufacturing of servers but also essential for the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where the use of automated assembly can enhance productivity and ensure consistent quality.

Today, engineering teams using DFX (Design For X, such as design for manufacturability), design for assembly, and design for maintainability face three major challenges. Firstly, they can only conduct analysis through existing 3D modeling CAD software and the CAD models themselves, which are dimensionally perfect and do not take into account actual tolerances. Moreover, traditional CAD systems cannot consider the functions of specific robots and cannot simulate the actual performance of these machines during the assembly process. These limitations are equally applicable to the design and manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where the interaction between robotic components and the physical parts being assembled needs to be carefully modeled and optimized. Secondly, the cost of building initial prototypes can be prohibitively high, especially for components like GPUs. In the context of manufacturing Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, the cost of prototyping can also be a significant barrier, especially when dealing with complex designs and specialized materials. Finally, physical prototypes require ordering parts and waiting for their delivery before assembly. This results in a long preparation time between the maturity of the design and the team’s ability to analyze how it will be assembled, a problem that plagues both high-tech manufacturing and the production of industrial equipment like Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment.

Virtual Design Platform Solutions

To address these challenges, manufacturers, including my company Bright Machines, are turning to solutions such as Nvidia’s Omniverse platform, as well as standards for simulation like the Universal Scene Description (USD) format. Although CAD designs are virtual, they need to incorporate as many physical properties as possible, and the simulation tools provided by Omniverse attempt to bridge the “gap between simulation and reality.” At the same time, the USD format, a standardized representation of 3D scenes, serves as a neutral file format in CAD systems, enabling physical simulation, photorealistic rendering, and data synchronization among users.

These virtual design platform solutions hold great promise for the manufacturing of not only AI servers but also Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment. In this rich environment, stakeholders with varying levels of expertise can handle 3D data without the need for CAD expertise. Manufacturing engineers find this particularly valuable for simulating complex servers and electronic devices, and Omniverse’s platform-based open standards approach enables better interoperability when validating virtual assemblies and integrates digital twins of production equipment within the same environment. For manufacturers of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, these tools can be used to simulate the entire assembly line, test different configurations, and optimize the placement of robotic arms and other components to ensure seamless and efficient production.

Early Design Validation and Continuous Improvement

In these design areas, issues discovered during the prototype stage often trigger iterative design changes. For example, if a robotic gripper needs to pick up and install a heat sink on a circuit board, the team needs to verify that the end-effector of the robotic arm has sufficient operating space. Similarly, in the design of a Bathroom Fixture Assembly Equipment, engineers need to ensure that robotic components can accurately handle and assemble delicate fixtures without causing damage. Depending on the specific issue, manufacturers can simulate these processes using CAD data and adjust the design before creating physical prototypes. Without this capability, changes will spread throughout the development process, leading to increased delays.

Since approximately 70% of the cost of a new product depends on initial design choices, and up to 95% of the cost is determined when the design is completed, it is crucial to identify problems early. The DFAA principles can help design engineers validate robotic assembly requirements from the start, while considering other design factors that may have higher priority, such as power consumption, latency, and heat dissipation requirements in server design, or durability, ease of use, and water resistance in the design of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment. These considerations directly impact automation implementation. For example, in computer server assembly, Bright Machines’ dedicated robotic cells are designed with full consideration of the capabilities and limitations of such automation systems and can handle process tasks such as inserting DIMMs into motherboards. In the case of Sanitary Ware Automatic Assembly Machines, similar robotic cells can be designed to handle tasks like fitting pipes, attaching fixtures, and ensuring proper alignment, all while taking into account the specific requirements and constraints of the product.

The data from these production lines then becomes the input for the design engine, driving improvements across the DFX series and other design considerations, making each generation of products more productive. Our own micro-factory has achieved a first-pass yield rate of up to 98%, which means that for every 100 units, less than two units require rework. This level of efficiency and quality can also be achieved in the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment by leveraging virtual simulation and DFAA principles to continuously refine and optimize the design and assembly processes.

Applying Virtual Simulation to Robotic Automation

Before implementing designs based on automated assembly principles, manufacturers need to evaluate their readiness through several key steps:

- Assess how changes that occur when issues are discovered during the prototyping stage will propagate through the development process and where time is spent in the lifecycle. This evaluation is essential for understanding the potential impact of design changes on the overall production timeline, whether it’s for AI servers or Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment.

- Evaluate which assembly steps in the current process are the most time-consuming or error-prone, and whether these issues can be addressed through design modifications or automation. In the production of Bathroom Fixture Assembly Equipment, for instance, identifying the most challenging assembly steps can help manufacturers focus their efforts on optimizing those specific areas using virtual simulation and automated assembly techniques.

- Measure the “churn rate” of your current process – how many design iterations typically occur and in which areas do you spend the most time making changes? This metric provides valuable insights into the efficiency of the design process and can help manufacturers determine where virtual simulation can have the greatest impact in reducing the number of iterations and improving overall productivity.

These evaluations will help designers identify the areas where virtual simulation will have the greatest impact and virtually validate the process. Ultimately, it will lead to faster deployment speeds and fewer physical iterations. As the manufacturing industry hurtles towards an era defined by rapid technological change and insatiable demand for innovation, the integration of virtual simulation and automated assembly design is not just an option—it’s a necessity. This dynamic duo has the potential to reshape the very fabric of product development, enabling companies to bring groundbreaking technologies and high-quality products, whether they are advanced AI servers or efficient Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, to market at speeds previously unimaginable. The journey from concept to creation is no longer bound by the limitations of physical prototypes and trial-and-error approaches. Instead, it’s a streamlined, data-driven process that empowers manufacturers to make informed decisions, iterate quickly, and stay ahead of the curve. In this new age of agile product development, those who embrace these transformative tools and methodologies will not only survive but thrive, setting the standard for a future where innovation knows no bounds and the possibilities of manufacturing are truly limitless.