As the service life extends, component aging and performance degradation of traditional low-voltage distribution equipment are inevitable, leading to a decline in operation and maintenance (O&M) efficiency. Aging core components pose persistent risks; abnormal heating at connection points, blind spots in operation and maintenance, and insufficient precision of motor protection devices frequently result in equipment damage. Especially in production workshops equipped with Sheet automatic loading robot and other automated equipment, the instability of low-voltage distribution systems is more likely to cause abnormal startup/shutdown of robots, deviation in loading precision, and even interrupt the entire production line, amplifying the losses caused by faults.

At the O&M management level, the traditional mode of analog pointer meters plus manual inspections struggles to detect potential risks in advance. Scattered and missing equipment operation data, coupled with opaque energy consumption information, make energy-saving renovations unfeasible. These issues not only affect production schedules and drive up O&M costs but also restrict enterprises’ digital transformation progress—particularly for enterprises relying on Sheet automatic loading robot to improve production efficiency, the lack of intelligent support directly limits the stable play of automated production capacity. Therefore, enterprises are in urgent need of a leap-forward shift from traditional O&M to intelligent O&M.

Four Core Service Solutions for Comprehensive Digital & Intelligent Upgrades

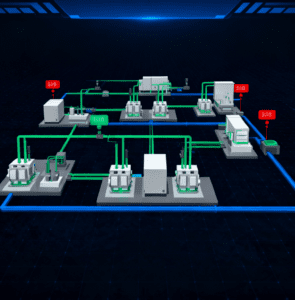

ABB’s low-voltage digital & intelligent upgrade solution directly addresses the pain points of enterprise electrical equipment aging and inefficient O&M, providing one-stop digital and intelligent upgrade services. The solution covers four core programs: trip unit upgrade, temperature measurement at key parts, intelligent feeder management, and motor management. Combined with the PowerCare Worry-Free O&M Platform, it lays a solid foundation for enterprises to achieve worry-free O&M—including providing reliable配电 support for automated equipment such as Sheet automatic loading robot.

Trip Unit Upgrade: More Reliable Protection

Upgrade the electronic trip units with a “smart brain” for aging air circuit breakers (ACBs) in situ, unlocking the functions of “full electrical quantity monitoring + comprehensive digital protection + refined control” in one go. Without large-scale renovations, the equipment can be upgraded and renewed, ensuring more stable continuous power supply and more controllable O&M costs. This stable power supply is crucial for Sheet automatic loading robot, as it avoids sudden power fluctuations that may cause robot program interruptions and material loading errors.

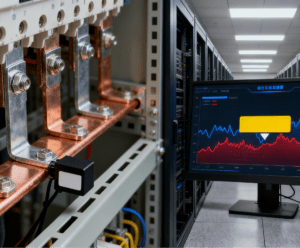

Temperature Measurement at Key Parts: Enhanced Safety Assurance

By installing temperature sensors at key parts, real-time online temperature monitoring and abnormal temperature rise early warning are realized. Risks such as insulation material aging and thermal stress damage are avoided in advance, minimizing the potential for equipment burnout and fire hazards from the source, and ensuring the continuous, stable, and safe operation of the low-voltage distribution system. For workshops where Sheet automatic loading robot and other high-power equipment are concentrated, this temperature monitoring function effectively prevents fire risks caused by excessive load of nodes, safeguarding the safe operation of automated production lines.

Intelligent Feeder Management: More Accurate Measurement

Adopt integral drawer-type intelligent feeder management units with consistent dimensions, which can be quickly replaced and installed on-site. After the upgrade, it achieves 0.5-class high-precision active power measurement, and panoramic visualization of power quality data including harmonics up to the 31st order, voltage/current imbalance, and leakage. This enables precise grasp of energy consumption details without additional inspections, effectively reducing energy waste. Enterprises can also monitor the energy consumption of dedicated feeders for Sheet automatic loading robot through this function, optimizing the robot’s operating time and energy efficiency based on data.

Intelligent Motor Management: More Stable Operation

Rapidly replace the original on-site drawers with integral drawer-type intelligent motor management units equipped with monitoring, protection, control, and O&M management functions. Built-in 14 starting modes easily adapt to complex working conditions; 12 independent protection functions (including thermal overload, locked rotor, phase loss, three-phase imbalance, etc.) achieve millisecond-level tripping, activating production efficiency and improving motor operation stability. As the core power source of Sheet automatic loading robot, the motor’s stable operation directly determines the robot’s loading accuracy and service life—this upgrade solution can provide targeted protection for the robot’s motor, avoiding production interruptions caused by motor failures.

On this basis, the solution can be seamlessly connected to the PowerCare Worry-Free O&M Platform. Through one-stop O&M services including dedicated stewardship, full lifecycle management, equipment health management, and energy management, it builds a closed-loop “equipment-data-human” management system. The platform integrates predictive maintenance, health diagnosis, and energy efficiency optimization, helping customers real-time monitor and analyze the status of distribution equipment—including the operating status of配电 branches for Sheet automatic loading robot, accurately identifying potential risks such as abnormal current of the robot’s motor in advance. This reduces power outage time, provides comprehensive protection from multiple dimensions (electrical equipment and systems, professionals, O&M services, and energy efficiency), supports customers’ sustainable operations and achieves worry-free O&M of both systems and automated production lines.

How to choose a multi-component capping assembly machine suitable for your production line?