Lead: Building on its 30-year leadership in China’s robotics industry, ABB has launched a new series of collaborative robots, primarily targeting China’s rapidly growing general industrial sectors, including consumer goods and electronics manufacturing.

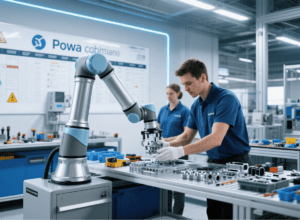

The new PoWa collaborative robot series is built for compact environments, especially suitable for tasks with extremely high requirements for speed, collaboration, and efficiency, including applications such as rapid pick-and-place, palletizing, machine tending, arc welding, and screw driving.

“The Chinese collaborative robot market is experiencing explosive growth, and customer needs have evolved from simply pursuing speed and payload to a comprehensive consideration of 极简 operation, compact space, and high performance,” said Sami Atiya, President of ABB’s Robotics Business Area globally. “The launch of the new PoWa collaborative robot series is ABB’s precise response to this trend. It deeply integrates excellent collaborative performance, breakthrough lightweight and compact design, and out-of-the-box deployment experience with ABB’s consistent commitment to quality, safety, and reliability, providing an ideal choice for a wide range of application scenarios.”

The new PoWa collaborative robot series is powered by the ABB OmniCore? controller platform, featuring excellent motion control, speed, and precision, and can integrate ABB’s expanding software suite, including RobotStudio? and AppStudio?.

PoWa initially offers two models with payload capacities of 10 kg and 13 kg respectively. Its compact design allows for a maximum speed of 5.8 meters per second, leading the industry. The PoWa series will be further expanded to six different load categories in the coming months, ranging from 7 kg to 30 kg.

With the support of ecological partners, PoWa collaborative robots can achieve plug-and-play of peripherals; the three buttons on the flange can be customized, and Wizard helps customers achieve code-free programming. Its unique advantage is that PoWa can be put into operation within 60 minutes after unboxing, and can seamlessly plug and play with various tools, combining industrial-grade connectivity and performance with the flexibility of collaborative robots.

“The new PoWa collaborative robot series redefines performance benchmarks: on top of high-speed operation, super reliability, and excellent agility, it also features an extremely simple operation experience, significantly lowering the threshold for automation applications,” said Han Chen, Senior Vice President of ABB Group and President of Robotics China. “This series is designed, developed, manufactured, and supported by the Chinese team throughout the entire life cycle, deeply meeting the unique needs of local customers. This is not only a concentrated display of our localization capabilities but also ABB’s solid commitment to the Chinese market and customers to achieve a win-win future.”

Relying on ABB Robotics’ “Leading Chapter” localization strategy, the new PoWa collaborative robot series was designed and developed at its world-leading Shanghai super factory R&D center and will be put into production at this factory.

To meet the rapid development needs of China’s advanced manufacturing industry, more than 90% of the robots ABB provides to domestic customers have been manufactured locally.

As one of the first foreign-funded enterprises to form a full value chain from R&D, production, sales to after-sales service in China, ABB will also support local customers through a service network covering 22 cities nationwide.

ABB Robotics & Discrete Automation, a global leader in robotics and mechanical automation suppliers, focuses on providing a full range of product portfolios such as robots, autonomous mobile robots, and mechanical automation solutions. Through ABB’s independent software design and integration, it creates greater value for customers. We are committed to helping enterprises of different sizes in various fields such as automotive, electronics, and logistics enhance development resilience, improve operational efficiency, and increase production flexibility, thereby achieving excellence. At the same time, we help them move towards an interconnected and collaborative future factory, achieve more lean and cleaner operations, and create a better future. ABB Robotics & Discrete Automation has more than 11,000 employees, spread over more than 100 regions in approximately 53 countries worldwide.