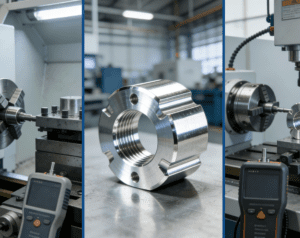

High-speed cutting refers to a machining technology that adopts a cutting speed much higher than the conventional one. Generally speaking, it can be called high-speed cutting when the cutting speed exceeds 5 to 10 times that of traditional cutting. High-speed cutting usually employs high-speed spindles, advanced cutting tools and optimized machining parameters to achieve efficient and high-precision machining.

The Principle of High-Speed Cutting

The principle of high-speed cutting is mainly based on the following aspects:

Reduced Cutting Force

During the high-speed cutting process, the cutting force decreases significantly as the cutting speed increases. This is because the temperature of the cutting deformation zone rises in high-speed cutting, which reduces the yield strength of the material and thus decreases the cutting force. In addition, the contact time between the cutting tool and the workpiece is extremely short during high-speed cutting, which also helps to reduce the cutting force.

Dispersed Cutting Heat

In high-speed cutting, although the amount of cutting heat generated per unit time increases due to the high cutting speed, the cutting heat is mainly concentrated near the cutting edge of the tool. Before the heat can be conducted to other parts of the workpiece and the tool, it is quickly taken away by the chips. Therefore, high-speed cutting can effectively reduce the thermal deformation of the workpiece and improve machining accuracy.

Prolonged Tool Life

Although the cutting temperature of the tool is relatively high in high-speed cutting, the wear of the tool is slowed down due to the reduced cutting force and dispersed cutting heat. In addition, high-speed cutting usually adopts advanced tool materials and coating technologies, which further extend the tool life.

Advantages of High-Speed Cutting

Improved Production Efficiency

The high cutting speed of high-speed cutting can greatly shorten the machining time. At the same time, due to the reduced cutting force, the power consumption of the machine tool is correspondingly reduced, which enables a higher feed rate and further improves production efficiency.

Enhanced Machining Quality

High-speed cutting can reduce cutting force and thermal deformation, thereby improving machining accuracy and surface quality. In addition, the chips become thinner during high-speed cutting, which is conducive to chip removal, reduces interference factors in the machining process, and further improves machining quality.

Wide Application Range

High-speed cutting technology can process various materials, including steel, cast iron, aluminum alloy, titanium alloy, etc. For some difficult-to-machine materials such as superalloys and cemented carbide, high-speed cutting can also achieve good machining results.

Reduced Production Cost

Although high-speed cutting requires the use of advanced machine tools, cutting tools and machining parameters, the overall production cost can be reduced due to factors such as improved production efficiency, high machining quality and long tool life.

Key Technologies of High-Speed Cutting

High-Speed Spindle Technology

The high-speed spindle is a key component for realizing high-speed cutting. High-speed spindles usually adopt electric spindle technology, featuring high rotational speed, high precision and low vibration. At present, the rotational speed of high-speed spindles can reach tens of thousands or even hundreds of thousands of revolutions, providing strong power support for high-speed cutting.

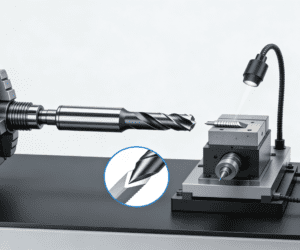

Cutting Tool Technology

High-speed cutting has extremely high requirements for cutting tools. The tools need to have high hardness, high strength, high heat resistance and good wear resistance. Meanwhile, the geometric shape and coating technology of the tools also need to be optimized to meet the requirements of high-speed cutting. At present, the commonly used tool materials for high-speed cutting include cemented carbide, ceramics, cubic boron nitride (CBN), etc.

CNC System Technology

High-speed cutting requires precise motion control and high-speed data processing capabilities. The CNC system needs to quickly respond to machining instructions to achieve high-precision trajectory control and high-speed interpolation operations. In addition, the CNC system should also have powerful programming functions and intelligent machining optimization functions to improve machining efficiency and quality.

Cooling and Lubrication Technology

A large amount of cutting heat generated during high-speed cutting needs to be discharged timely and effectively, otherwise it will affect the machining quality and tool life. Cooling and lubrication technology can effectively reduce the cutting temperature, reduce tool wear and improve machining quality. At present, the commonly used cooling and lubrication methods include air cooling, oil mist cooling, minimum quantity lubrication (MQL), etc.

Application Fields

Aerospace Field

In the aerospace field, the requirements for the precision and quality of parts are extremely high. High-speed cutting technology can machine high-precision and complex-shaped aerospace parts, such as aircraft engine blades and fuselage structural components. At the same time, high-speed cutting can also improve production efficiency, reduce production costs and meet the rapid development needs of the aerospace industry.

Automotive Manufacturing Field

The automotive manufacturing field also has very high requirements for production efficiency and machining quality. High-speed cutting technology can machine high-precision automotive engine parts, transmission parts, molds, etc. In addition, high-speed cutting can also realize lightweight design, improving the performance and fuel economy of automobiles. To match the efficient mass production rhythm brought by high-speed cutting, many automotive component manufacturers have also equipped automatic carton packaging machines in the post-processing link—these machines can automatically complete carton forming, part positioning, sealing and labeling for the machined parts, avoiding efficiency bottlenecks caused by manual packaging, ensuring consistent packaging quality of precision parts, and further linking the high-efficiency machining process with the logistics link to realize the integration of production and distribution.

Mold Manufacturing Field

Mold manufacturing is one of the important application fields of high-speed cutting. High-speed cutting can machine high-precision and complex-shaped molds, such as injection molds, stamping molds, die-casting molds, etc. Meanwhile, high-speed cutting can shorten the mold manufacturing cycle and improve the quality and service life of molds.

Electronics and Electrical Appliances Field

In the electronics and electrical appliances field, high-speed cutting can machine high-precision electronic components and electrical appliance casings, etc. At the same time, high-speed cutting can also realize miniaturized machining to meet the demand for miniaturization and lightweight in the electronics and electrical appliances industry.