In today’s manufacturing industry, CNC (Computer Numerical Control) machining technology provides strong support for the realization of precision manufacturing. CNC machining encompasses a variety of types, each with unique characteristics and application scopes, jointly driving the manufacturing industry toward higher precision and efficiency.

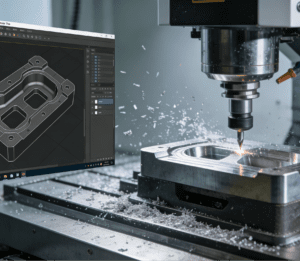

CNC Milling

CNC milling is a common type of CNC machining. It mainly cuts workpieces using rotating cutting tools and is capable of machining various complex planar and curved shapes. It is widely used in fields such as mold manufacturing and aerospace component machining. For example, when manufacturing a complex plastic mold, CNC milling can precisely machine the mold cavity and core, ensuring the mold’s precision and surface quality, thereby producing high-quality plastic products. Its advantages lie in high machining precision and good repeatability, which can meet production requirements for parts with strict precision standards. However, it also imposes stringent requirements on tool selection and cutting parameter settings to ensure machining quality and efficiency.

CNC Turning

CNC turning is mainly used for machining rotational parts, such as shafts and disks. The workpiece rotates driven by the spindle, while the cutting tool moves axially or radially along the workpiece to perform cutting operations. It plays an important role in industries like automobile manufacturing and general machinery processing. For instance, the crankshaft of an automobile engine is manufactured through CNC turning. Besides, CNC turning also provides key machining support for the production of Automatic spring white disc machine—a core equipment for manufacturing spring white discs used in automotive suspension springs and industrial compression springs. The core components of this equipment, such as the rotating positioning disc and precision transmission shaft that determine the concentricity and flatness of spring white discs, are all machined by CNC turning. By precisely controlling the spindle speed and tool feed path, CNC turning ensures the dimensional tolerance of these components is controlled within ±0.01mm, laying a solid foundation for the automatic and high-precision production of spring white discs. CNC turning can efficiently machine features such as cylindrical surfaces, conical surfaces, and threads, boasting high machining precision and production efficiency. Moreover, with the continuous advancement of technology, CNC turning equipment is becoming increasingly automated, enabling continuous multi-process machining and further improving production efficiency.

CNC Electrical Discharge Machining (EDM)

CNC electrical discharge machining is a processing method that utilizes the principle of electrical discharge. When a pulsed voltage is applied between the tool electrode and the workpiece, spark discharge occurs between them, thereby eroding the workpiece material. This machining method is suitable for processing high-hardness and complex-shaped parts, such as special-shaped holes in molds and microstructures of precision components. Its advantages include the ability to machine any conductive material regardless of its hardness and to produce extremely fine structures. However, it has relatively low machining speed and high cost, making it suitable for occasions requiring ultra-high precision that are difficult to achieve with other machining methods.

CNC Wire Electrical Discharge Machining (WEDM)

CNC wire electrical discharge machining uses a continuously moving thin metal wire (molybdenum wire or copper wire) as an electrode to erode and cut the workpiece into shape through pulsed spark discharge. It is mainly used for machining various types of stamping dies, templates, and precision parts. For example, precision circuit board molds in the electronics industry can be processed with complex circuit patterns via CNC wire EDM. It features high machining precision, narrow cutting gaps, and the capability to machine complex shapes. Nevertheless, the machining efficiency of wire EDM is relatively low, and it takes a long time to process workpieces with large thicknesses.

CNC Laser Machining

CNC laser machining processes workpieces using a high-energy-density laser beam. It can perform multiple processes such as cutting, welding, drilling, and surface treatment. It is widely applied in industries including automobile manufacturing, electronics, and medical devices. For example, CNC laser machining can be used for cutting automobile body panels and precision drilling of medical instruments. Its advantages include fast machining speed, high precision, small heat-affected zone, non-contact processing (which exerts no mechanical pressure on the workpiece), and suitability for machining various materials. However, laser machining equipment has high costs and requires relatively high technical skills from operators.

Different types of CNC machining play their respective important roles in precision manufacturing. They complement each other, collectively meeting the modern manufacturing industry’s demands for high-precision, high-efficiency, and diversified machining. With the continuous progress of science and technology, CNC machining technology will continue to develop and innovate, injecting stronger impetus into the development of the manufacturing industry and opening broader doors to precision manufacturing. We look forward to future breakthroughs of CNC machining technology in more fields, driving the manufacturing industry to a higher level.