5G Speeds Up the Digital Transformation of Manufacturing

The manufacturing industry is undergoing a profound transformation driven jointly by 5G and the Internet of Things (IoT). Currently, more than two-thirds (approximately 62%) of manufacturing enterprises worldwide have adopted IoT technology in their production or assembly processes, leveraging it for equipment connectivity, process monitoring, and data analysis. With the introduction of 5G technology, this trend has been further accelerated.

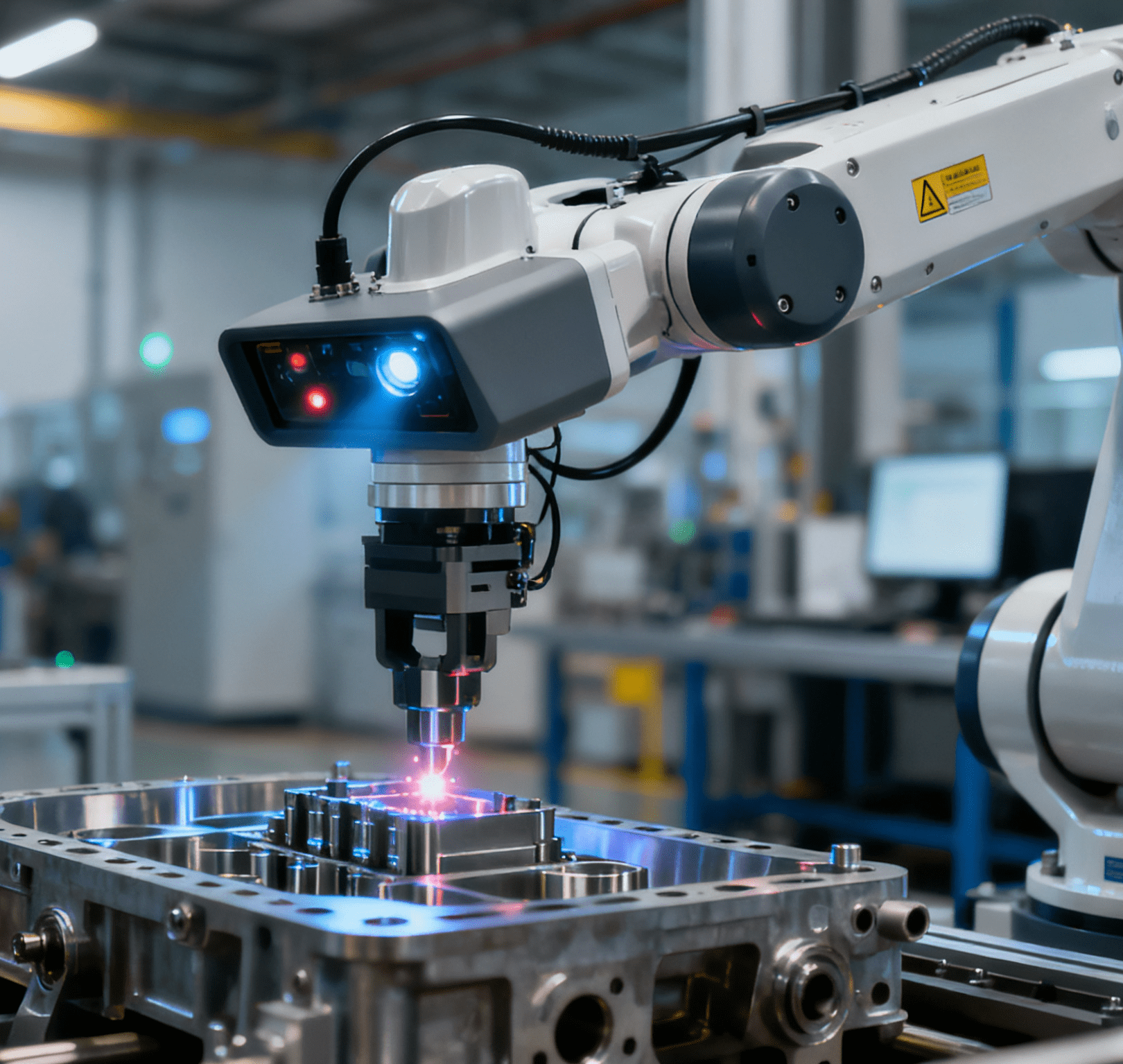

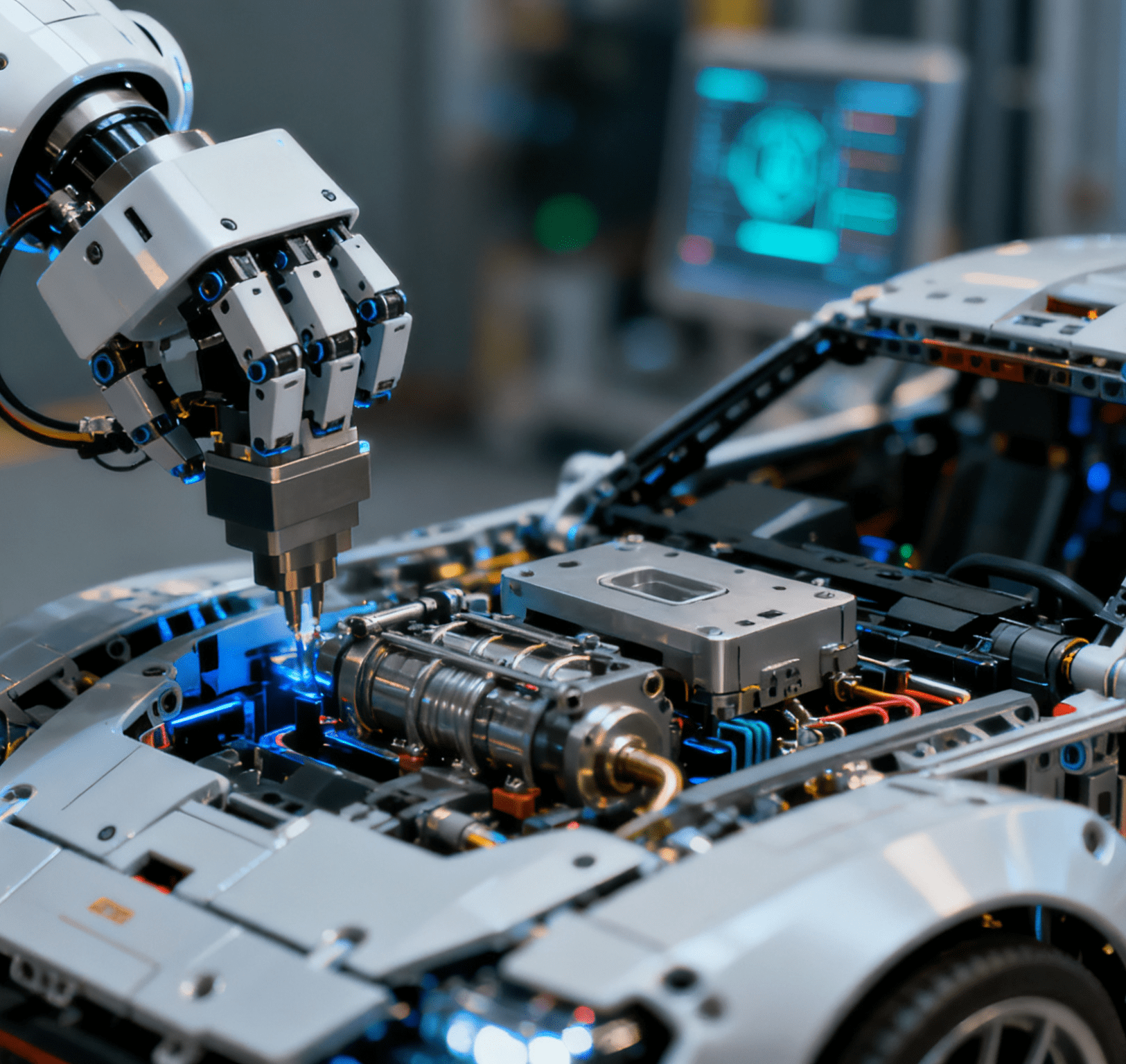

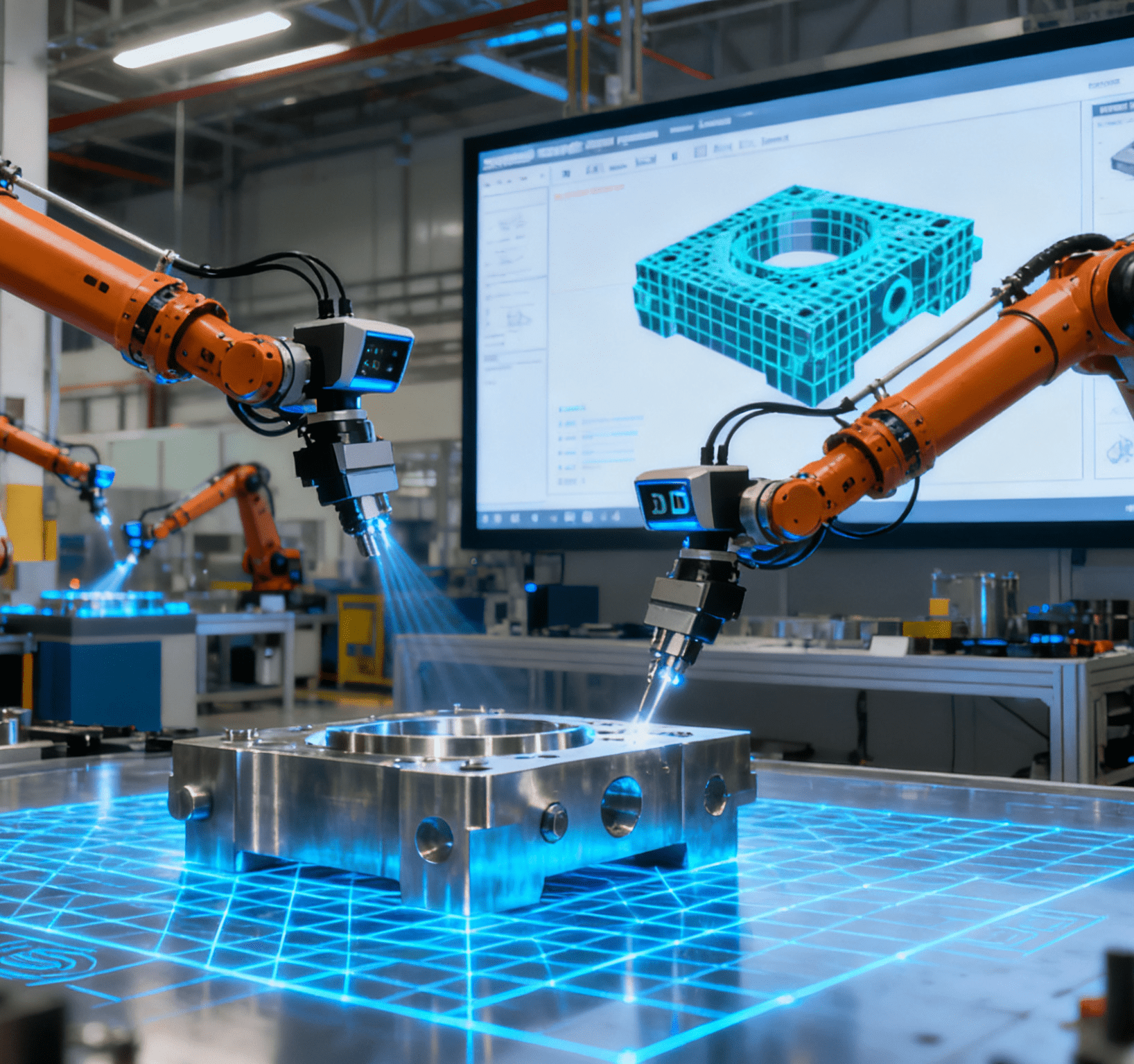

Characterized by high speed, low latency, and large bandwidth, 5G networks not only significantly enhance the efficiency of existing IoT systems but also provide a technical foundation for advanced application scenarios such as real-time robot control, predictive maintenance, remote monitoring, digital twins, and Injection Molded Parts Automated Assembly System with Auto-Loading—these systems enable fully automated feeding and high-precision assembly of injection-molded components, revolutionizing production efficiency in sectors like automotive parts and electronic device manufacturing. However, the adoption of 5G also brings more complex security challenges, forcing manufacturing enterprises to re-examine their cybersecurity systems while advancing intelligence and automation.

Expanding Threat Surface: Security Challenges in the 5G Environment

The widespread deployment of 5G has led to exponential growth in the number of IoT devices, resulting in an unprecedented expansion of the attack surface. As sensors, cameras, actuators, and robotic systems continue to be connected, network topologies have become increasingly complex, making the security models of the traditional 4G era no longer adequate.

Studies show that the connectivity brought about by digital transformation has significantly increased the exposure of industrial systems.

Building a Defense System: Private 5G Networks and Network Slicing Strategies

In the 5G IoT security system, the secure design of network architecture serves as the first line of defense. Attackers typically attempt to infiltrate enterprises’ core networks by compromising end devices, aiming to access critical data or disrupt production activities. Therefore, strengthening network-layer defense is crucial to ensuring the security of manufacturing operations.

Private 5G Networks

Private 5G networks provide manufacturing enterprises with a closed and secure communication environment, enabling data to be processed and stored at local edges and reducing exposure to external networks. This architecture can effectively protect sensitive production data and intellectual property while enhancing network controllability and response speed. Private 5G networks offer significant advantages in large-scale industrial IoT deployments, particularly suitable for B2B scenarios and critical manufacturing processes—including those relying on systems like the Injection Molded Parts Automated Assembly System with Auto-Loading, where data integrity and operational continuity are paramount.

Network Slicing

Network slicing technology allows a single 5G network to be divided into multiple independent virtual subnets or “slices,” each of which can be customized and configured according to different business scenarios and security requirements. Through traffic isolation and hierarchical security policies, manufacturing enterprises can reduce the attack surface and prevent cross-slice spread of threats. For instance, even if an attacker breaches one slice, the impact cannot extend to other business domains—such as isolating the network slice dedicated to the Injection Molded Parts Automated Assembly System from slices handling general office traffic to contain potential risks.

However, improper slice configuration may lead to cross-slice contamination, unauthorized access, or data leakage. Therefore, secure network slicing requires precise policy management and continuous security verification.

AI and Machine Learning: Key Drivers of Intelligent Defense

In the complex environment of 5G IoT, traditional security protection mechanisms can no longer meet the demands of security analysis for massive devices and real-time data. Artificial Intelligence (AI) and Machine Learning (ML) technologies are emerging as the core of the next-generation security defense system.

Research indicates that ML models can continuously monitor network traffic and device behavior, identify abnormal patterns in real time, and issue early warnings of potential threats. These algorithms can detect attack signs that are difficult for humans to perceive—such as abnormal command sequences or changes in communication frequency—from large volumes of data in an extremely short time, thereby significantly improving the accuracy and response speed of threat detection. This is especially critical for systems like the Injection Molded Parts Automated Assembly System with Auto-Loading, where even a momentary disruption could halt production.

Furthermore, Generative Artificial Intelligence (GenAI) and Large Language Models (LLMs) are being explored for use in automated security policy generation, threat intelligence analysis, and attack simulation. These technologies can enable adaptive security defense in private 5G network environments, enhancing the resilience and responsiveness of the entire industrial IoT infrastructure through dynamic learning and policy optimization.

5G IoT Security: From Passive Response to Active Defense

The security of 5G IoT should not be a post-deployment remedy; instead, it should be integrated into the overall architecture during the system design phase. Only by incorporating the concept of “Security by Design” into all stages of 5G IoT planning, deployment, and operation and maintenance can potential risks be fundamentally mitigated. This principle applies equally to critical systems like the Injection Molded Parts Automated Assembly System with Auto-Loading, where security must be baked into every component from the start.

In addition, manufacturing enterprises must recognize that relying solely on internal security capabilities is often insufficient to address the evolving threat landscape. Establishing collaborative defense mechanisms with telecommunications operators, system integrators, and IoT solution providers has become a key direction for safeguarding the security of the 5G IoT ecosystem.

Supply chain security is also a critical link. The globalized production model, reliance on third-party suppliers, and digital transformation have all expanded the potential attack surface. Statistics show that approximately 68% of organizations experienced supply chain-related cyberattacks in 2022. Therefore, integrating cybersecurity into supply chain risk management systems is essential for protecting IoT deployments and the security of embedded systems—including those powering the Injection Molded Parts Automated Assembly System with Auto-Loading.

Conclusion: Security and Innovation Must Go Hand in Hand

The integration of 5G and IoT has brought unprecedented efficiency and innovation potential to the manufacturing industry, but it has also reshaped the cybersecurity landscape. For manufacturing enterprises to fully unlock the value of 5G IoT—whether through real-time data analytics, advanced robotics, or systems like the Injection Molded Parts Automated Assembly System with Auto-Loading—they must prioritize both security and innovation at the strategic level.

Only by advancing security strategies in tandem with the construction and operation of 5G IoT, establishing defensive network architectures, introducing intelligent security technologies, and strengthening cross-ecosystem collaboration can the manufacturing industry achieve truly secure, reliable, and sustainable digital upgrading amid this wave of transformation.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine