Following Ruihu Mould’s announcement of plans to raise no more than 750 million yuan for robot-related projects, another mould enterprise has made a significant move. Recently, Zhengyu Technology, a key backbone enterprise in China’s motor core mould industry, issued an announcement stating its intention to sign a Strategic Cooperation Agreement with the Ninghai County Investment Promotion Center. The company plans to invest 2.11 billion yuan in Ninghai County from 2025 to 2030 to build projects for precision component manufacturing equipment, process equipment, precision structural parts, and humanoid robot precision modules and components. This initiative aims to expand production capacity for existing businesses and establish capacity for emerging product fields.

Three-Phase Investment Layout: 2.11 Billion Yuan to Tap Robot Component Track

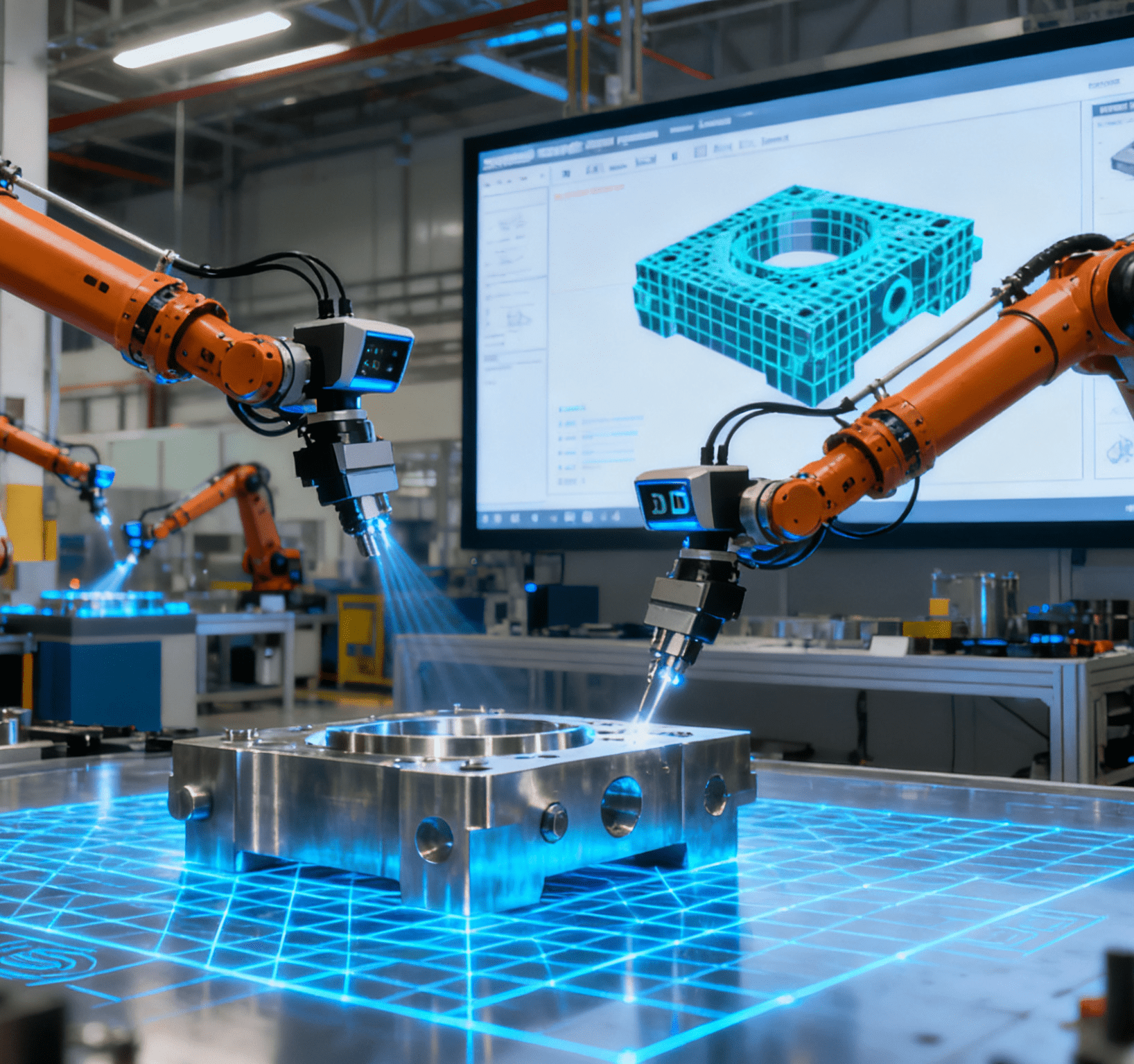

The cooperation will be implemented in three phases: The first phase involves building a “Project with an Annual Output of 1 Million Sets of Manufacturing Equipment and Precision Structural Parts for Precision Components”, covering approximately 51.3 mu (1 mu ≈ 0.0667 hectares). The second phase will construct a “Project with an Annual Output of 1 Million Sets of Process Equipment and Precision Structural Parts for Precision Components”, covering about 61.8 mu. The third phase focuses on the “Project with an Annual Output of 1 Million Sets of Precision Modules and Components for Humanoid Robots”, spanning around 100 mu. The announcement reveals that the investment agreement for the first phase, with a total investment of approximately 750 million yuan, is scheduled to be signed alongside the Strategic Cooperation Agreement soon. These funds will be used to build production workshops and a R&D and experimental center.

A Leader in the Precision Progressive Die Industry: From Moulds to New Energy Structural Parts

The mould industry is regarded as the “golden key to industrial modernization”, as its technological level directly determines the development ceiling of high-end manufacturing. Weber Consulting data shows that from 2011 to 2023, China’s mould industry grew steadily driven by manufacturing upgrading, downstream demand from automotive, 3C, and new energy sectors, and domestic technological breakthroughs. The market scale reached 11.896 billion yuan in 2019, doubling that of 2011 with a growth rate far exceeding the global average, highlighting the demand potential of the “world factory”.

This growth momentum will persist. With the advancement of “Made in China 2025”, industries such as new energy vehicles, photovoltaics, and semiconductors have boosted demand for high-precision moulds. It is expected that by 2026, China’s mould manufacturing industry’s sales revenue will rise to 444.5 billion yuan. This growth reflects not only downstream expansion but also the transformation of domestic enterprises from “low-end OEM” to “high-end R&D”, and the strengthening of their “cornerstone role” in the high-end manufacturing system.

With over 20 years of experience in the mould industry, Zhengyu Technology, a major supplier of motor core moulds for China’s top 10 compressor manufacturers, focuses on R&D of high-end progressive stamping moulds. Leveraging its mould technology foundation, the company has gradually expanded downstream: entering motor core precision stamping in 2013 and new energy vehicle power lithium battery precision structural parts in 2015, forming an industrial chain covering “moulds – precision stamping – new energy structural parts”. This business expansion path aligns with classic universal systems model examples like the value chain extension model, where enterprises optimize the entire system by integrating upstream and downstream resources to enhance core competitiveness.

Cross-Bord

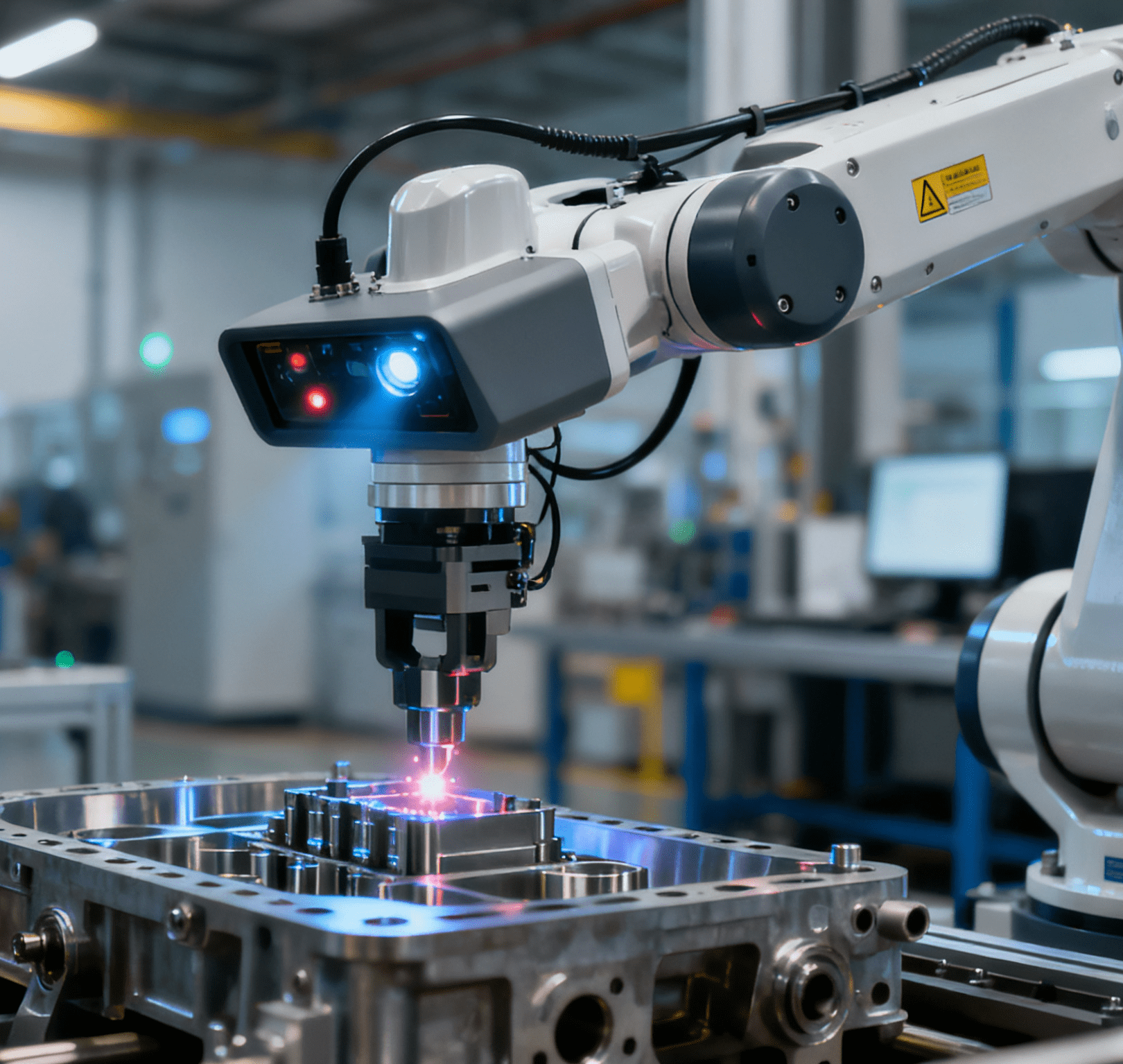

er Expansion into Robotics: Technological Advantages Secure Initial Orders

Ahead of the humanoid robot industry boom, Zhengyu Technology seized opportunities through technological transfer. Motor drive technology, central to humanoid robots, directly affects motion accuracy and efficiency—an area where Zhengyu’s accumulated capabilities in ultra-precision mechanical part design and manufacturing provide a natural advantage. In October 2024, the company established a subsidiary for emerging fields, focusing on R&D and manufacturing of precision robot components. Currently, it has three product series: reverse planetary roller screws, linear actuators, and dexterous hand precision components, and has secured small-batch orders from domestic and foreign customers.

In the first three quarters of 2025, Zhengyu Technology achieved total operating revenue of 6.593 billion yuan (up 31.47% year-on-year), net profit attributable to parent company shareholders of 412 million yuan (up 138.93% year-on-year), and non-net profit (after deducting non-recurring gains and losses) of 398 million yuan (up 153.42% year-on-year).

Zhengyu Technology’s 2.11 billion yuan investment is both a consolidation of existing advantages and a strategic layout in the future high-end manufacturing track—from precision moulds to new energy structural parts, and now to humanoid robot core components.

Epilogue: Robot Component Market Booms, Domestic Enterprises Chase Technological Catch-Up

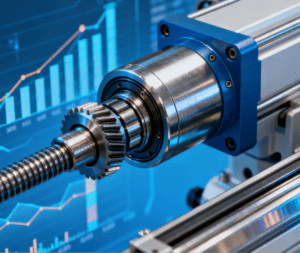

The accelerating expansion of the robot market continues to drive demand for core components. Take planetary roller screws, a key focus of Zhengyu’s layout: they convert robot joint rotational motion into linear motion, directly impacting motion accuracy and efficiency. As a core component of humanoid robot joints, a single planetary roller screw can cost up to 10,000 yuan, accounting for 15%-25% of the total machine cost. Huajing Industry Research Institute forecasts that by 2030, the global market scale of planetary roller screws in humanoid robots will reach 26.79 billion yuan. However, international giants have long dominated the high-end market, leaving ample room for domestic enterprises in technological breakthroughs and market share expansion.

The broader robot component market also shows strong growth. Boyan Consulting data indicates that the global robot component market reached 85 billion US dollars in 2024 and is expected to grow to 93 billion US dollars in 2025, providing solid support for the core component segment.

Key questions lie ahead: Can domestic enterprises narrow the technological gap with international giants? Can production capacity expansion keep pace with market demand growth? How will application popularization driven by price declines feed back into industrial chain upgrading? The answers will not only reshape the component market pattern but also influence China’s voice in the global humanoid robot industry competition.