Table of Contents

ToggleThe New Path of Human-Machine Skill Transfer: How Flexible Automatic Assembly Equipment Cultivates “Intelligent Industrial Workers”

Introduction

In the process of flexible automatic assembly equipment accelerating the substitution of traditional workstations, “machine replacement” triggers not a labor crisis but a “skill reconstruction revolution”—industrial workers are transforming from “repetitive executors” to “human-machine collaborators.” This article analyzes three core mechanisms: AR immersive training, digital twin practical training, and skill data precipitation. Combining the upgrading of Germany’s dual-system education and China’s industry-education integration practices, it reveals how flexible equipment becomes a “bridge for skill transfer,” enabling workers to evolve from “afraid of machines” to “proficient in intelligence,” and ultimately constructing a new labor ecosystem of “human factor enhancement.”

I. Three Subversions of the Traditional Skill System: Capacity Leap from “Experience-Based” to “Digital”

The popularization of flexible equipment has broken the century-old skill inheritance logic, giving rise to three capability paradigm shifts:

1. Operational Skills: From “Limb Proficiency” to “System Cognition”

- Traditional Bottleneck: Statistics from an automotive electronics factory show that veteran workers need 3 months to master the manual assembly sequence of 20 parts, while flexible equipment supports mixed production of over 200 models, making traditional muscle memory skills completely ineffective.

- New Capability Requirements:

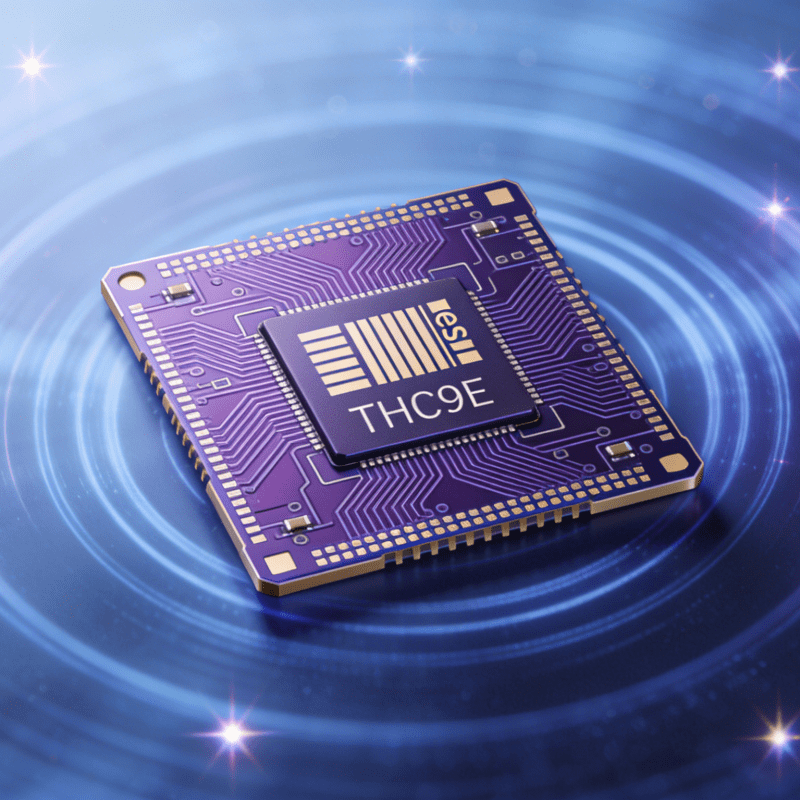

Operation of equipment digital interfaces (e.g., calling process parameters via HMI with an error ≤0.5%);

ii. Decision-making in abnormal scenarios (when equipment reports errors, quickly locate based on a library of 30+ historical failure cases with a response time ≤2 minutes).

2. Quality Control: From “Sensory Judgment” to “Data Interpretation”

- Technological Change: In precision bearing assembly, flexible equipment collects over 100 torque and vibration data in real time. Workers need to learn to interpret SPC control charts (e.g., identify trend alarms of 7 consecutive rising points) instead of relying on “touch” to judge tightness.

- Capability Upgrade: A German-funded enterprise implemented a “data literacy program,” increasing workers’ accuracy in identifying abnormal data from 60% to 92% and reducing the missed inspection rate of quality issues by 85%.

3. Collaboration Models: From “Single-Person Operation” to “System Collaboration”

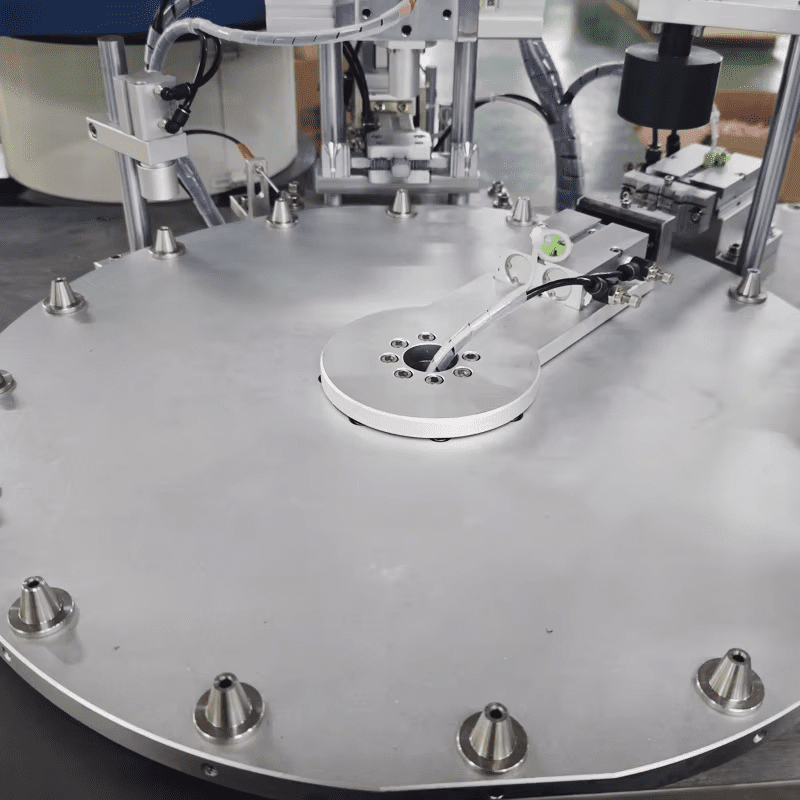

- Scenario Reconstruction: When a 6-axis robotic arm and workers share a 1.5㎡ collaboration zone, workers need to master “dynamic human-machine division of labor”—for example, the robotic arm completes chip mounting with an accuracy of ±0.02mm, while workers simultaneously perform visual appearance inspection (efficiency increased by 30% compared to traditional division).

II. Intelligent Skill Cultivation System: Building an Immersive Learning Environment Where “Equipment Is the Teacher”

Flexible equipment creates a new capability cultivation platform through “digitalization of physical operations, scenario-based training processes, and standardization of skill certification.”

1. AR-Enhanced Training: Making Equipment an “Interactive Textbook”

- Technical Implementation:

- Equipment twin modeling: Create 1:1 scale virtual equipment with Unity engine, supporting gesture operations (e.g., “grab virtual fixture→rotate 90°→align with slot”), and force feedback gloves simulate 0.5N-level resistance perception;

- Fault simulation system: Preset 50 typical anomalies (such as “vision positioning deviation +5μm” and “torque sensor signal drift”), and trainees must complete diagnostics in a virtual environment (average response time ≤3 minutes as qualified).

- Training Effectiveness: After introducing the AR training system, a leading domestic 3C enterprise shortened the onboarding cycle for new employees from 45 days to 12 days, reduced equipment misoperation rates from 25% to 3%, and decreased training costs by 60%.

2. Digital Twin Training Factory: Accumulating “Combat Experience” in a Safe Environment

- Three-Layer Training Architecture:

Basic layer: Simulate equipment start-stop and parameter setting through Minecraft industrial modules, suitable for 0-based trainees to familiarize themselves with the interface;

ii. Advanced layer: Access real equipment data (such as robotic arm movement trajectories and real-time sensor values) for “risk-free trial and error” in digital twins (e.g., intentionally input wrong parameters to observe equipment responses);

iii. Combat layer: (link) with real production lines, where trainees’ operations in the virtual environment are directly mapped to physical equipment (safety thresholds are set to automatically cut off power in case of wrong operations). - Industry Case: The “twin training center” of Siemens’ Chengdu Digital Factory increased workers’ success rate in handling complex model switching from 50% to 95%, and the confidence index for first independent operations rose from 30% to 85%.

3. Skill Data Precipitation: Establishing a “Human-Machine Collaboration Experience Library”

- Knowledge Graph Construction:

- Collect over 3,000 hours of human-machine collaboration videos, and analyze the optimal collaboration distance (optimal value 1.2m, error ±0.1m) and action coordination rhythm (workers’ waiting time should be ≤2 seconds when the robotic arm is running) between workers and robotic arms through computer vision;

- Develop an “experience extraction algorithm”: Extract 300+”golden operation points” from over 100,000 operations of excellent workers (such as “when the equipment beeps, the left thumb should immediately press the emergency stop preparation button”).

- Application Achievements: The “skill digital twin system” of a Japanese home appliance factory enables ordinary workers to achieve 90% of the operational efficiency of skilled workers, while the training cycle is shortened from “6 months of master-apprentice teaching” to “4 weeks of system training.”

III. Professional Role (Reshaping): Three Transformation Paths from “Operators” to “Intelligent Collaborators”

1. Equipment Operation and Maintenance Direction: Cultivating “Embedded Problem Solvers”

- Capability Matrix:

- Primary: Master equipment 5S management and simple fault code query (e.g., locate alarm No. E0123 through the equipment manual);

- Intermediate: Use an oscilloscope to detect sensor signals (accuracy ±1%) and read equipment register data through the Modbus protocol;

- Advanced: Write custom PLC subroutines (e.g., develop error-proofing algorithms for specific workpieces).

- Certification System: The “Flexible Manufacturing Equipment Operation and Maintenance Technician” certification launched by the Chinese Mechanical Engineering Society is divided into three levels, with pass rates of 60%, 40%, and 15%, respectively. Certified personnel have an average salary increase of 35%.

2. Process Optimization Direction: Cultivating “Data-Driven Process Experts”

- Growth Path:

- Basic stage: Learn to use Excel to analyze the correlation between process parameters and yield (e.g., draw scatter plots to identify key factors);

- Advanced stage: Master Minitab’s DOE experimental design and design 3-factor 2-level parameter optimization experiments;

- Expert stage: Use Python to write machine learning models to automatically predict the best assembly pressure (the expert model of a medical device factory has a prediction accuracy of 94%).

- Typical Case: The worker engineer team of a US-funded medical device factory analyzed 50,000 pieces of assembly data and found that “when the environmental humidity >60%, the glue curing time needs to be extended by 10 seconds.” This single improvement increased the yield by 2.3%, saving ¥800,000 in costs annually.

3. Production Management Direction: Shaping “Human-Machine Collaboration Schedulers”

- Core Skills:

- Work order allocation based on the MES system (balancing equipment load rate and worker proficiency, target deviation ≤5%);

- Handling of (emergencies): Complete human-machine task redistribution within 10 minutes when equipment at a workstation fails (e.g., convert uncompleted processes of the robotic arm to manual temporary replacement).

- Tool Empowerment: The “Human-Machine Collaboration Scheduling APP” developed by Haier COSMOPlat shortens the scheduling time of frontline team leaders from 2 hours to 15 minutes, and increases the on-time order delivery rate from 75% to 92%.

IV. Global Practices: Innovative Explorations from Germany’s Dual System to China’s Industry-Education Integration

1. German Model: School-Enterprise Co-construction of “Flexible Manufacturing Training Factories”

- Implementation Details:

- Enterprises (such as Bosch) provide second-hand flexible equipment (retaining 80% of precision), and schools build a “teaching-oriented digital twin system.” Students complete 90% of basic training in a virtual environment before practicing on real equipment;

- Assessment standards are linked to equipment KPIs: Students need to complete model switching for 10 products within 45 minutes, and the first-piece pass rate after model switching must be ≥95% to be qualified.

- Effectiveness Data: Pilot projects in Baden-Württemberg, Germany, show that students trained under this model have an overall equipment efficiency (OEE) 22% higher than traditional apprentices within 3 months of employment.

2. Chinese Innovation: Tripartite Collaboration among “Equipment Manufacturers + Vocational Colleges + Leading Enterprises”

- Typical Case: Flexible Manufacturing College of Shenzhen Polytechnic

- Equipment layer: DJI donates 10 sets of four-axis robot assembly units, and Inovance Technology provides a PLC programming training platform;

- Curriculum system: Develop modular courses such as Human-Machine Collaboration Strategies for Flexible Equipmentand Basic Applications of Industrial Software, with each module corresponding to 1 real production task (e.g., assembling smart speakers, with a yield ≥98% for credits);

- Employment docking: Enterprises such as Huawei and BYD give priority to hiring students who pass the three-dimensional assessment of “equipment operation + process optimization + exception handling,” with starting salaries 40% higher than ordinary graduates.

V. Future Trends: Building a “Human Factors Engineering-Oriented” Skill Evolution System

Brain-Computer Interface Assisted Training

Develop EEG headbands to monitor trainees’ attention (e.g., distraction is determined when the alpha wave ratio >30%), and adjust training difficulty in real time. Experiments by a Japanese start-up show that this technology can increase the learning efficiency of complex operations by 50%

Digital Skill Passports

Establish “skill digital twins” supported by blockchain technology to record workers’ operation data on different flexible equipment (such as cumulative model switching times and abnormal handling success rates), forming traceable capability certificates. It is expected that by 2030, 80% of manufacturing job recruitments will be based on digital skill passports.

Human-Machine Collaboration Maturity Assessment

Develop a “Human-Machine Collaboration Capability Maturity Model” (HC-CMM), which divides five levels of capability from three dimensions: “equipment operation, data interpretation, and collaborative decision-making,” guiding enterprises to systematically improve workers’ intelligent collaboration levels.

Conclusion

The skill transfer triggered by flexible automatic assembly equipment is essentially a “redivision of human intelligence and machine intelligence”—machines undertake repetitive physical labor and precise calculations, while humans focus on creative decision-making and abnormal scenario handling. This transformation is not “skill deprivation” but “capacity upgrading”: through AR training, equipment becomes an “intelligent tutor”; through digital twins, “risk-free trial and error” is achieved; and through data precipitation, experience is transformed into “inheritable digital assets.” Industrial workers are evolving from “bystanders of equipment” to “collaborative designers of intelligent systems.” For enterprises, cultivating “intelligent industrial workers” is not a cost expenditure but the last piece of the “human-machine collaboration system” puzzle—when workers can achieve “data intercommunication, decision-making sharing, and capacity symbiosis” with equipment, the ultimate form of flexible manufacturing—an “adaptive human-machine community”—truly becomes possible. In this skill revolution, equipment is the tool, data is the language, and talent is always the core variable that makes flexible manufacturing full of warmth and creativity.