Automatic Circlip Feeding System: Revolutionizing Precision Component Handling in Industrial Assembly

In the realm of precision mechanical assembly, circlips (retaining rings) play a critical role in securing components such as bearings, gears, and shafts. Traditional manual or semi-automated feeding methods for these small, elastic components—ranging from 2mm to 100mm in diameter—suffer from inherent limitations: inconsistent orientation (error rate ≥5%), slow cycle times (15–30 seconds per clip), and high labor intensity. The Automatic Circlip Feeding System emerges as a transformative solution, integrating vibratory bowl technology, intelligent vision guidance, and adaptive control to streamline high-precision circlip handling in automotive, electronics, and medical device manufacturing.

- Core Technical Architecture: Precision Meets Efficiency

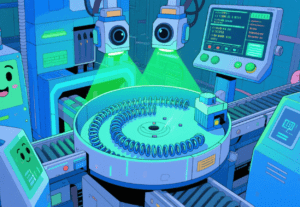

The system synergizes mechanical engineering, machine vision, and adaptive control to achieve reliable circlip feeding with minimal human intervention. Its architecture comprises four interdependent subsystems:

- Vibratory Bowl Feeding Module

The foundation of the system, vibratory bowls are optimized for circlip orientation:

- Customized Bowl Tracks: Engineered with spiral grooves, chutes, and reject gates to sort circlips (internal/external types) by diameter, thickness, and opening orientation

- Adaptive Vibration Control: Electromagnetic actuators adjust amplitude (0.1–2mm) and frequency (20–150Hz) in real-time, preventing clip jams or deformation

- Throughput Optimization: Handles 100–300 clips per minute (depending on size), with orientation accuracy exceeding 99.5% for standard circlips

- Vision-Guided Orientation & Inspection

A high-resolution vision system ensures precise clip alignment:

- Dual-Camera Setup: Overhead 2D camera (5MP+) for planar orientation and side-view 3D sensor for depth measurement, achieving ±0.1mm positioning accuracy

- AI-Powered Feature Recognition: Deep learning algorithms (e.g., Halcon) identify critical features like clip openings, burrs, or surface defects with 99.8% accuracy

- Dynamic Error Correction: Adjusts for bowl output variations (±0.5mm positional offset) using servo-driven positioning stages, ensuring consistent clip presentation

- Adaptive Gripping & Transfer Mechanism

End-effectors combine precision actuation with smart sensing:

- Multi-Config Gripper Tooling: Pneumatic microgrippers for small clips (2–10mm) and magnetic grippers for larger sizes (10–100mm), with force control (0.5–10N) to prevent deformation

- Quick-Change Tooling: Swaps between gripper types in <10 seconds, supporting rapid adaptation to different clip designs

- Anti-Static Design: Conductive materials and ionizing bars for ESD-sensitive environments (e.g., electronics assembly)

- Intelligent Control Software

The system’s digital backbone enables seamless automation:

- Recipe Management: Stores 200+ circlip specifications (ISO, ANSI, custom) with one-click activation, reducing changeover time to <3 minutes

- Real-Time Monitoring: Tracks key metrics (OEE, cycle time, defect rate) and generates alerts for bowl blockages or tool wear

- IIoT Integration: Connects to MES systems via OPC UA, enabling data-driven process optimization and full traceability

- Industrial Applications: Solving Circlip Handling Challenges

- Automotive Component Assembly

In powertrain and chassis systems, the system excels at:

- Bearing Retaining Ring Feeding: Placing 10–50mm circlips in wheel hubs and transmissions with ±0.2mm radial alignment, critical for preventing bearing failure

- Engine Valve Retainer Handling: Orienting small circlips (2–8mm) in engine valve trains using anti-vibration grippers, reducing noise and wear

Case Study: A leading automotive OEM reduced circlip feeding defects by 90% and increased assembly line speed by 35% after deploying 40 systems, achieving annual savings of $1.2 million in labor and rework costs.

- Electronics & Consumer Devices

For miniature circlips in connectors and small motors:

- Micro-Circlip Feeding: Handling 2–5mm circlips for smartphone camera modules with vacuum-assisted grippers, ensuring no damage to delicate components

- Wearable Device Assembly: Orienting tiny retaining rings in smartwatch hinges with ±0.05mm accuracy, supporting slim form factor designs

- ESD Protection: Anti-static bowl coatings and grounding systems for electronics manufacturing environments

- Medical Device Manufacturing

In surgical tools and implantable devices:

- Sterile Circlip Handling: 316L stainless steel bowls and FDA-compliant coatings for medical-grade circlips in syringe pumps and orthopedic implants

- Micro-Surgical Instrument Feeding: Precision handling of 0.5–2mm circlips for laparoscopic tools, meeting ISO 13485 cleanliness standards

- Traceability Compliance: Record-keeping for every circlip’s feeding timestamp and orientation data, supporting regulatory audits

- Industrial Machinery & Aerospace

For heavy-duty circlips in harsh environments:

- Large-Diameter Circlip Feeding: Handling 50–100mm circlips for industrial gearboxes with magnetic grippers capable of 50N gripping force

- Aerospace Component Feeding: Anti-corrosion coatings and vibration-resistant designs for circlips in aircraft engines and landing gear systems

III. Competitive Advantages Over Traditional Methods

| Performance Metric | Manual/Semi-Automatic Feeding | Automatic Circlip Feeding System |

| Orientation Accuracy | 90–95% | 99.5–99.9% |

| Cycle Time (per clip) | 15–30 seconds | 1–3 seconds |

| Changeover Time (new clip) | 20–40 minutes | <3 minutes |

| Defect Rate (mishandling) | 0.5–1% | <0.05% |

| Labor Requirement (per line) | 2–3 operators | 1 supervisor (remote monitoring) |

| Clip Variety Support | Limited (5–10 types) | 200+ types (modular tooling) |

- Technological Frontiers & Future Innovations

- AI-Driven Self-Optimization

Machine learning algorithms will:

- Predict optimal vibration parameters for new circlip designs, reducing setup time by 70%

- Analyze feeding data to identify subtle wear patterns in bowl tracks, triggering proactive maintenance alerts

- Adapt to variations in clip material (stainless steel, spring steel, plastic) for improved handling consistency

- 3D Vision & Dynamic Adjustment

Upgrades to structured light and ToF sensors will enable:

- Accurate feeding of complex-shaped circlips (e.g., snap rings with tabs or grooves)

- Real-time compensation for thermal expansion in high-temperature environments (e.g., engine assembly)

- 3D inspection of clip profiles to ensure compliance with tight tolerances

- Collaborative Robotics Integration

Dual-arm cobots (e.g., Universal Robots UR10e) with force-torque sensors are being developed for:

- Shared workspaces where robots handle circlip feeding while humans perform quality checks

- Flexible cells supporting small-batch, high-mix production with quick reconfiguration

- Sustainable Design Innovations

Key developments include:

- Energy-efficient vibration drives recovering 25% of braking energy

- Recyclable polymer bowl liners reducing waste in disposable medical device production

- Modular system designs enabling 80% component reuse across different clip feeding applications

Conclusion

The Automatic Circlip Feeding System represents a pivotal advancement in precision component handling, addressing the critical needs for speed, accuracy, and flexibility in modern manufacturing. By eliminating manual inefficiencies, reducing changeover times, and enabling data-driven quality control, it becomes an indispensable asset in smart factory ecosystems. As Industry 4.0 progresses, these systems will continue to evolve—integrating AI, 3D vision, and collaborative capabilities—to meet the ever-growing complexity of mechanical assembly, ensuring that even the smallest components like circlips are handled with unprecedented precision and reliability.

Keywords: Automatic Circlip Feeding System, Vibratory Bowl Feeder for Retaining Rings, Vision-Guided Circlip Orientation, Precision Component Handling System, AI-Powered Feeding Automation, Automotive Circlip Feeding Solution, Medical Device Circlip Handling, High-Speed Retaining Ring Feeder, Industrial Robotics Feeding System, Smart Factory Component Feeding

#Small Circlip Feeding for Electronics #Automotive Suspension Circlip Automation #Vibratory Bowl Feeder for Retaining Rings