Eye-Catching Industry Data: Robots Emerge as New Engine for Economic Transformation

Data from the China Machinery Industry Federation shows that in the first three quarters of 2025, the added value of China’s large-scale machinery industry increased by 8.7% year-on-year, 2.5 percentage points higher than the national industrial added value growth rate. Among them, the output of industrial robots rose by 29.8% year-on-year to 595,000 units, exceeding the total output of the entire previous year. Compared with the 5.2% growth rate of national large-scale industrial added value, the growth rate of industrial robot output is particularly prominent, highlighting the increasingly important position of the robot industry in the process of economic transformation and upgrading.

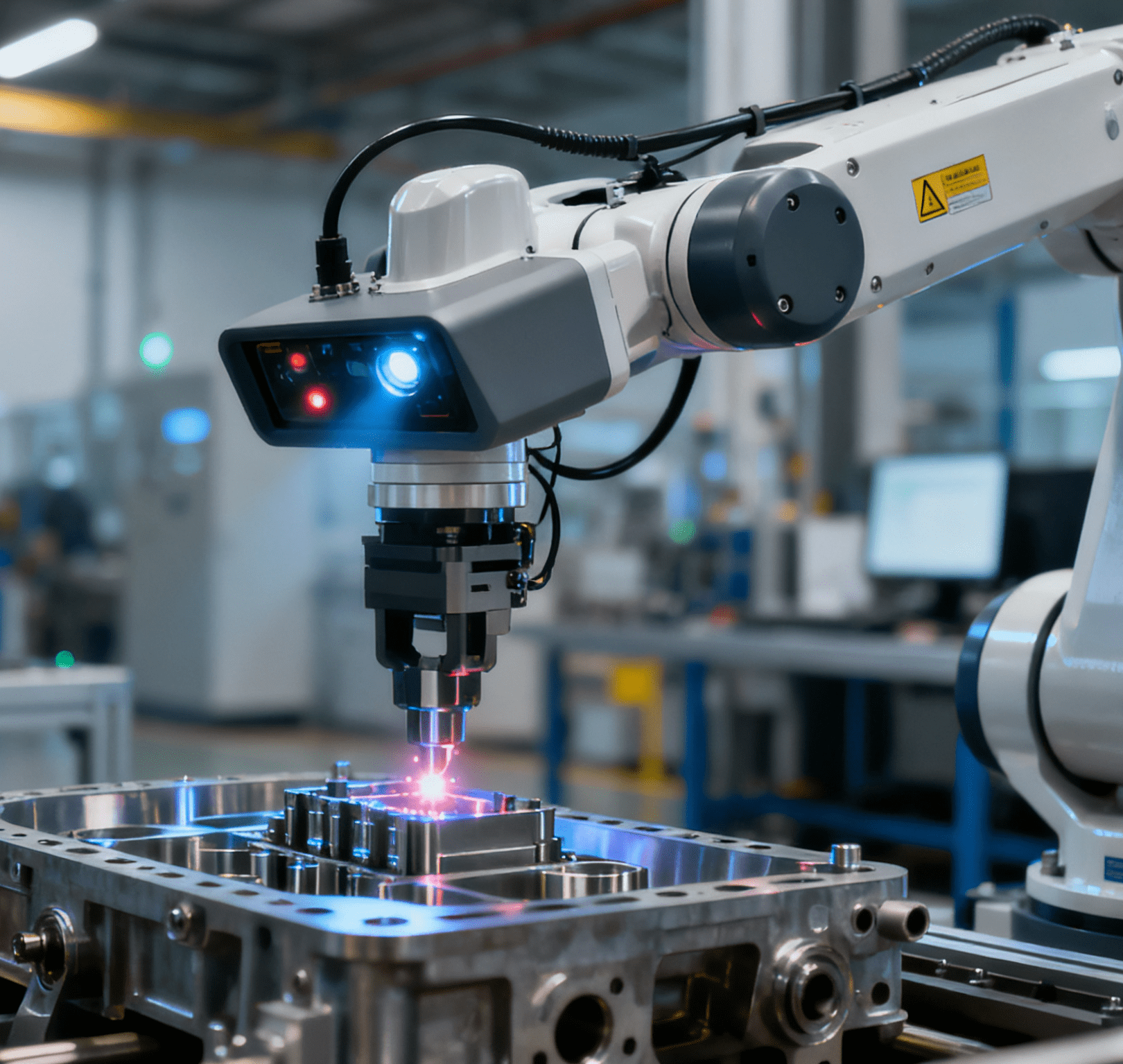

From the perspective of application fields, the development of the robot industry has achieved remarkable results. In the manufacturing sector, the application of robots has significantly improved production efficiency and product quality. In industries such as automobile manufacturing and electronic equipment production, industrial robots are widely used—they can accurately complete tasks such as welding, assembly, and handling, avoiding errors in manual operations and enhancing the stability and consistency of production. Specifically, in the pre-processing links of auto parts and structural components, Automated Material Handling for Leveling has become a key supporting technology: it integrates automatic feeding, precision leveling, and intelligent conveying, realizing continuous and stable material processing, which not only improves the flatness accuracy of workpieces by more than 30% but also reduces manual intervention by over 60%, effectively matching the high-efficiency production rhythm of modern factories. In the service sector, service robots have also gradually come to the fore: food delivery robots in hotels, dish-handling robots in restaurants, and cleaning robots in households have brought great convenience to people’s lives and work, while also promoting the intelligent development of the service industry.

Data from the General Administration of Customs also indicates that in the first three quarters of 2025, China’s export of industrial robots increased by 54.9%. This reflects the growing competitiveness of Chinese robot products in the international market. The robot industry not only plays a key role in domestic economic transformation but also has become a new calling card for China’s manufacturing industry to go global. With the continuous innovation of robot technology and the expansion of application scenarios, its role as an engine in economic transformation and upgrading will become even stronger, driving China’s economy toward high-quality development.

Multiple Enterprises Secure Over 100-Million-Yuan Financing; Capital Embraces the Robot Track Enthusiastically

In late October alone, four robot companies announced the completion of a total of approximately 2.4 billion yuan in financing, demonstrating capital’s high enthusiasm for this industry representing future technology. On October 27, Wuba Intelligent Technology (Hangzhou) Co., Ltd. completed its first round of strategic financing of about 500 million yuan, co-led by Guoxin Fund and Zhejiang Industrial Investment, with participation from many national and local government funds. The funds will be used to accelerate the construction of pilot test bases, break through core key technologies of embodied intelligence robots, and expand application scenarios in large-scale security and heavy industry. As a core embodied intelligence enterprise under China North Industries Group Corporation, Wuba Intelligent has focused on the business of humanoid robots and industrial quadruped robots since its establishment in 2022. It has achieved bulk deliveries and exports exceeding 100 million yuan in multiple segments, becoming a leading brand in the application side of the large-scale security field.

On the same day, Songyan Power (Beijing) Technology Co., Ltd. also announced the completion of nearly 300 million yuan in Pre-B round financing, led by Fangguang Capital with the participation of many well-known institutions. Since its establishment in September 2023, Songyan Power has maintained an intensive financing pace, completing multiple rounds of financing in 2025—this is its fourth round of financing within the year. A few days before announcing the financing, Songyan Power launched its first 10,000-yuan-level small-sized humanoid robot “Bumi”. The product stands 94 cm tall, weighs 12 kg, and has no less than 21 degrees of freedom. Orders exceeded 100 units within one hour of its launch, and the first batch of 500 units was sold out within two days. The enthusiastic market response also reflects the capital market’s optimism about its technical strength and commercial prospects.

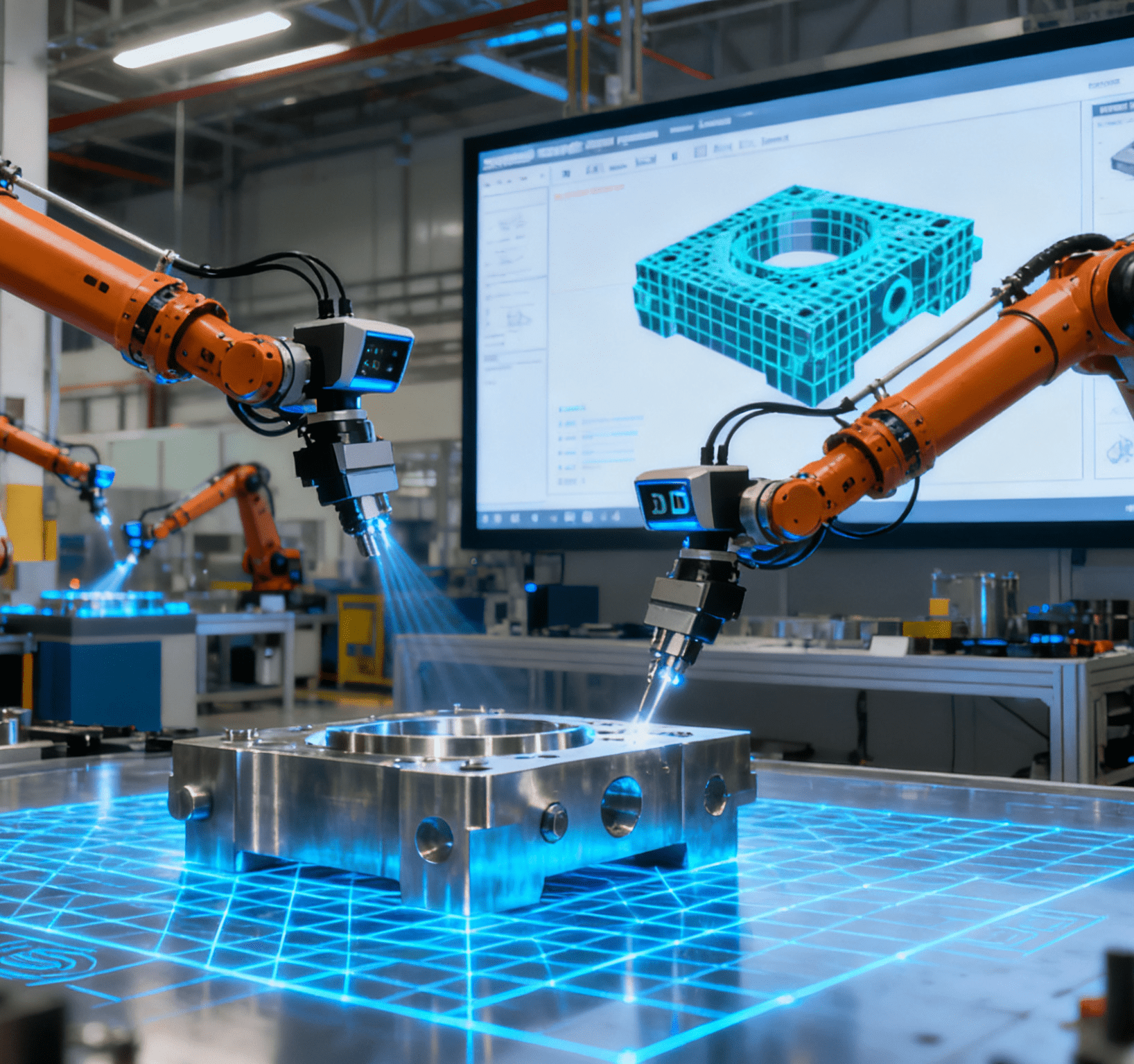

On October 24, Zhongke Diwuju (Hangzhou) Intelligent Technology Co., Ltd. completed nearly 100 million yuan in Angel and Angel+ round financing. This general embodied intelligence company, co-founded by alumni from the Institute of Automation of the Chinese Academy of Sciences and Tsinghua University, focuses on building embodied workstations and general intelligent robots for intelligent manufacturing factories. It has completed four rounds of financing within just one year of its establishment. Currently, it has become a “brain” supplier for leading domestic humanoid robot body companies, realizing the technical implementation of “one brain for multiple models”. Its independently developed body products have completed POC (Proof of Concept) verification on the production lines of Midea Group and a leading automobile enterprise, entering the small-batch supply stage, and plans to launch the second generation of integrated hardware-software embodied robot body products by the end of the year. Notably, its embodied workstations have been successfully applied in the coordination of Automated Material Handling for Leveling systems in automobile component factories, realizing intelligent scheduling between leveling equipment and subsequent welding robots.

On October 22, Leju (Shenzhen) Robot Technology Co., Ltd. announced the completion of nearly 1.5 billion yuan in Pre-IPO round financing, with the participation of many institutions. Leju Robot is one of the earliest domestic enterprises to enter the humanoid robot field. It has received 6 rounds of financing, is currently preparing for listing, and has completed a name change. The company adopts a differentiated strategy of “small-sized products first, full-sized products following” and has achieved breakthroughs in both the education and industrial fields. Its 30-70 cm educational robots have entered nearly 5,000 institutions across the country; the full-sized humanoid robot “Kuafu” series for industrial scenarios completed its 100th delivery in January this year, setting a domestic delivery record; and the 5G-A remotely controlled robot jointly launched with China Mobile and Huawei in March achieved commercial application in chassis welding at BAIC Off-Road Vehicle Factory. This welding application is also closely matched with Automated Material Handling for Leveling equipment in the front-end process, forming a seamless production link from material preparation to welding.

Technological Breakthroughs and Scenario Expansion Drive Industry Development on Dual Wheels

The robot industry is in a critical period of rapid technological iteration and continuous expansion of application scenarios—these two factors promote each other and jointly drive the industry to new heights. In terms of technological breakthroughs, the development of core technologies such as artificial intelligence, machine learning, and sensors has significantly improved the intelligence and autonomy of robots. Taking the dexterous hand technology of humanoid robots as an example, it is a key component for realizing refined operations and intelligent interaction, directly related to the robot’s “brain”. Tesla’s Optimus dexterous hand continues to iterate toward refinement and bionic design; the optimization of key components such as its motors, micro ball screws, tendons, and sensors has greatly improved the dexterity, load-bearing capacity, and perception ability of the dexterous hand. Once the optimization of the dexterous hand is completed, it means that the core hardware has nearly converged, which is an important step for robots to move toward large-scale mass production.

In the industrial field, the depth and breadth of robot applications continue to expand. In the automobile manufacturing industry, industrial robots undertake key processes such as welding, assembly, and handling. With the rise of new energy vehicles, robots are also increasingly used in battery production, motor assembly, and other links. In the electronics manufacturing industry, industrial robots can perform high-precision and high-efficiency operations in semiconductor production, mobile phone assembly, and other processes, meeting the increasingly miniaturized and refined production needs of electronic products. Moreover, industrial robots are no longer limited to single-unit operations—industrial scenarios with multi-body and multi-task collaboration have gradually become a reality. For example, robots such as Tianyi 2.0 and Tiangong 2.0 displayed by the Beijing Humanoid Robot Innovation Center work in collaboration to complete tasks such as inspection, sorting and quality inspection, and transportation and packaging. This breaks the traditional limitation of “one machine for one post”, realizes seamless collaboration across scenarios, and marks a leap from individual intelligence to group intelligence, bringing a new model to industrial automation. In the metal processing and structural parts manufacturing industries, the application of Automated Material Handling for Leveling has also realized collaborative operations with subsequent processing robots: the system can automatically identify material types and thicknesses, adjust leveling parameters in real time, and accurately convey leveled materials to the next process, forming a fully automated production line from material input to finished product output.

The service field is also an important direction for the expansion of robot applications. In the medical and elderly care field, products such as exoskeleton robots, intelligent walking-assist robots, and home service robots continue to emerge, covering typical scenarios such as households, communities, hospitals, and public spaces. They provide life assistance and rehabilitation care services for the elderly, disabled, and other groups, improving their quality of life. In the catering industry, pancake robots can produce authentic Tianjin-style pancakes in 3 minutes, coffee robots can accurately create latte art, skewer-roasting robots can automatically control temperature and flip skewers, and iced drink robots can complete operations such as rinsing, chilling, and pouring wine with one click. Combined with claw machine robots, carving robots, and holographic projection guided tours, they create an immersive experience of “eating while playing”, revolutionizing the catering service model.

The application of special robots in special scenarios has also made significant progress. In the military field, special robots can perform tasks such as reconnaissance, explosive ordnance disposal, and drone operations, reducing the risk of soldier casualties and improving battlefield survival capabilities. Their rapid deployment and adaptability have obvious advantages in the rapidly changing battlefield environment. In disaster rescue scenarios, special robots, relying on their autonomous navigation, environmental perception, and data analysis capabilities, can efficiently perform search and rescue work in disaster sites such as earthquakes and fires, reducing casualties. For example, in the ruins after an earthquake, special robots can go deep into dangerous areas to search for signs of life of survivors, providing key information for rescue work.

Industry Pattern Takes Shape; Localization and Ecologization Become Development Trends

Currently, the robot industry is showing a significant trend of accelerated localization and ecologization, and the industry pattern is gradually becoming clear. In terms of localization, China’s robot industry has made major breakthroughs. Data from the High-Tech Industry Research Institute (GGII) shows that in 2023, the market share of domestic industrial robots reached 52.45%, surpassing foreign brands for the first time in terms of sales volume. This milestone event marks that China’s industrial robot industry has reached an inflection point from quantitative to qualitative change. In the field of core components, localization is also advancing steadily. Taking collaborative palletizing robots as an example, the MIR 睿工业 (MIR Industry) report shows that their localization rate has surprisingly exceeded 90%. Huashengkong Intelligent Technology Co., Ltd., relying on its leading intelligent palletizing robot products, has firmly topped the list with a 64% market share, demonstrating the strong strength of “Made in China”. In the field of Automated Material Handling for Leveling, domestic enterprises such as Sany Heavy Industry and Zoomlion have also achieved key breakthroughs, with their products’ leveling accuracy reaching international advanced levels and localization rate of core components exceeding 75%, breaking the long-term monopoly of foreign brands.

In terms of ecologization, the robot industry ecosystem is increasingly improved, and the coordinated development trend of the upper, middle, and lower reaches of the industrial chain is obvious. Beijing Economic and Technological Development Zone has gathered more than 140 leading enterprises related to robots of various types, with an output value of over 10 billion yuan, basically forming an industrial chain system covering core components, complete machines, and application scenarios. Kepler Robotics has successfully introduced shareholders from multiple industrial listed companies through multiple rounds of financing, building multi-dimensional competitive advantages. It continues to make breakthroughs in hardware infrastructure while actively conducting strategic cooperation with high-quality channels and application investors to build a forward-looking layout integrating “technology – channels – market”. Guangdong has formed an intelligent robot industry pattern with Guangzhou, Shenzhen, Foshan, and Dongguan as the core and coordinated development in the Pearl River Delta. The province has initially established a complete industrial chain of “key components – complete machine manufacturing – integrated application” for intelligent robots. Its industrial robot output in 2024 accounted for 44% of the country’s total, ranking first in China for five consecutive years.

The formation of regional industrial clusters has further promoted the ecologization of the robot industry. Relying on the enabling advantages of information technology enterprises in the Software Valley, the intelligent special robot industrial cluster in Yuhuatai District, Nanjing has continuously improved the intelligence and digitalization level of its intelligent special robots. It now has 97 enterprises in related fields, including national manufacturing single champion enterprises and national specialized, refined, and innovative “little giant” enterprises. Industrial agglomeration areas such as “Robot Valley” and “Robot Bay” in Shenzhen, relying on a complete and fast-response industrial chain for robots and intelligent equipment, have attracted many enterprises to gather. For example, Orbbec 3D Technology Group Co., Ltd., which focuses on building “eyes” for robots, can meet with upstream and downstream partners within ten minutes here, greatly promoting collaborative innovation in the industry. In these clusters, Automated Material Handling for Leveling enterprises have also established close cooperative relationships with robot body manufacturers and system integrators, realizing rapid iteration of products and customized development for different scenarios.

Hidden Concerns Emerge Behind Prosperity; Capital Winter and Industry Challenges Coexist

Although the robot industry is currently developing well, Wang Chao, founder of Wenyuan Think Tank, pointed out in an interview with relevant media that the industry track is expected to enter a capital winter in the second half of this year or the next two years, and the elimination round will officially begin. The survival rule for enterprises will become extremely simple: the stronger the capital reserves, the longer the survival time. From the perspective of the market environment, with a large amount of capital pouring into the robot field, industry competition has become increasingly fierce, and the market has gradually become saturated. When the capital boom recedes, enterprises that lack core competitiveness and rely excessively on capital investment will face severe survival tests.

At the technical level, although robot technology has made significant progress, it still faces many challenges. There are still “chokepoint” technologies in high-end links—core technologies such as motion control algorithms, precision reducers, and high-precision sensors still lag behind international giants. The cost of a single humanoid robot is as high as hundreds of thousands of yuan, and the proportion of core components dependent on imports still exceeds 40%, which severely restricts the large-scale application of the industry. Even in relatively mature segments like Automated Material Handling for Leveling, high-end motion control systems and precision pressure sensors still rely on imports to a certain extent, leading to higher product costs and limiting the expansion of profit margins. At the market level, homogeneous competition has intensified. Many domestic manufacturers are crowded into the mid-to-low-end market, and price wars occur frequently, leading to the phenomenon of “increasing volume without increasing revenue”. Although the sales volume of industrial robots increased in 2024, the average profit margin of the industry decreased.

To address these challenges, enterprises need to proactively strengthen core technology research and development, especially breaking through “chokepoint” technologies in high-end components; optimize product structure, avoid homogeneous competition, and develop customized solutions for different industries; and strengthen industrial chain collaboration to jointly build a more resilient and innovative industrial ecosystem. For segments like Automated Material Handling for Leveling, enterprises should focus on improving the localization rate of high-end components, integrating AI algorithms to enhance adaptive capabilities, and expanding application scenarios to high-end manufacturing fields such as aerospace and precision instruments, thereby enhancing core competitiveness and coping with potential industry adjustments.