In the manufacturing industry’s unremitting pursuit of ultimate precision, the precision competition among CNC machines has never ceased. So, which one is truly the most precise CNC machine?

Ultra-Precision CNC Machine Tools in Core Fields: Precision Benchmarks

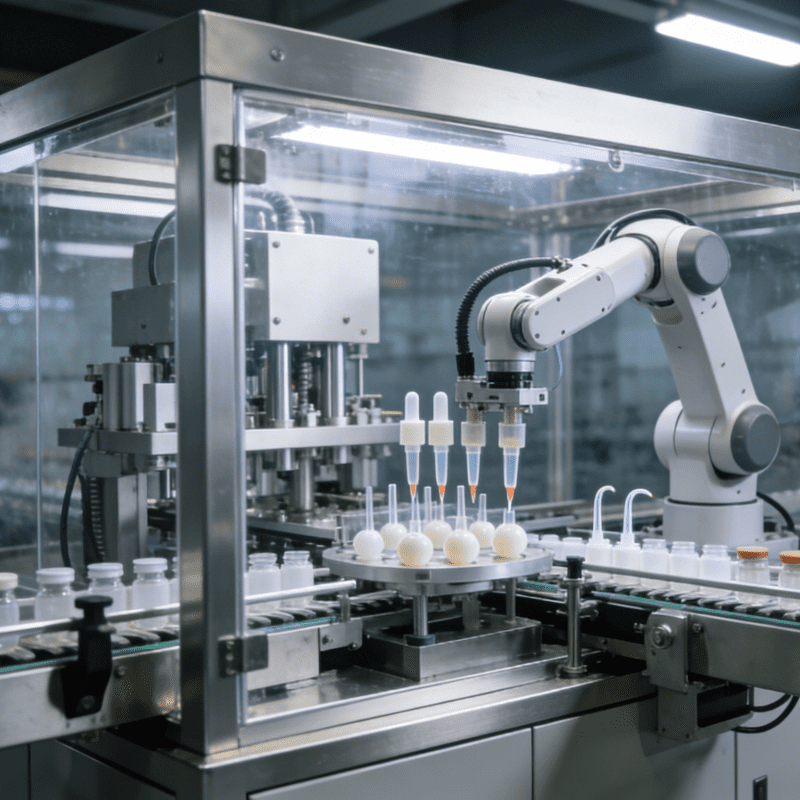

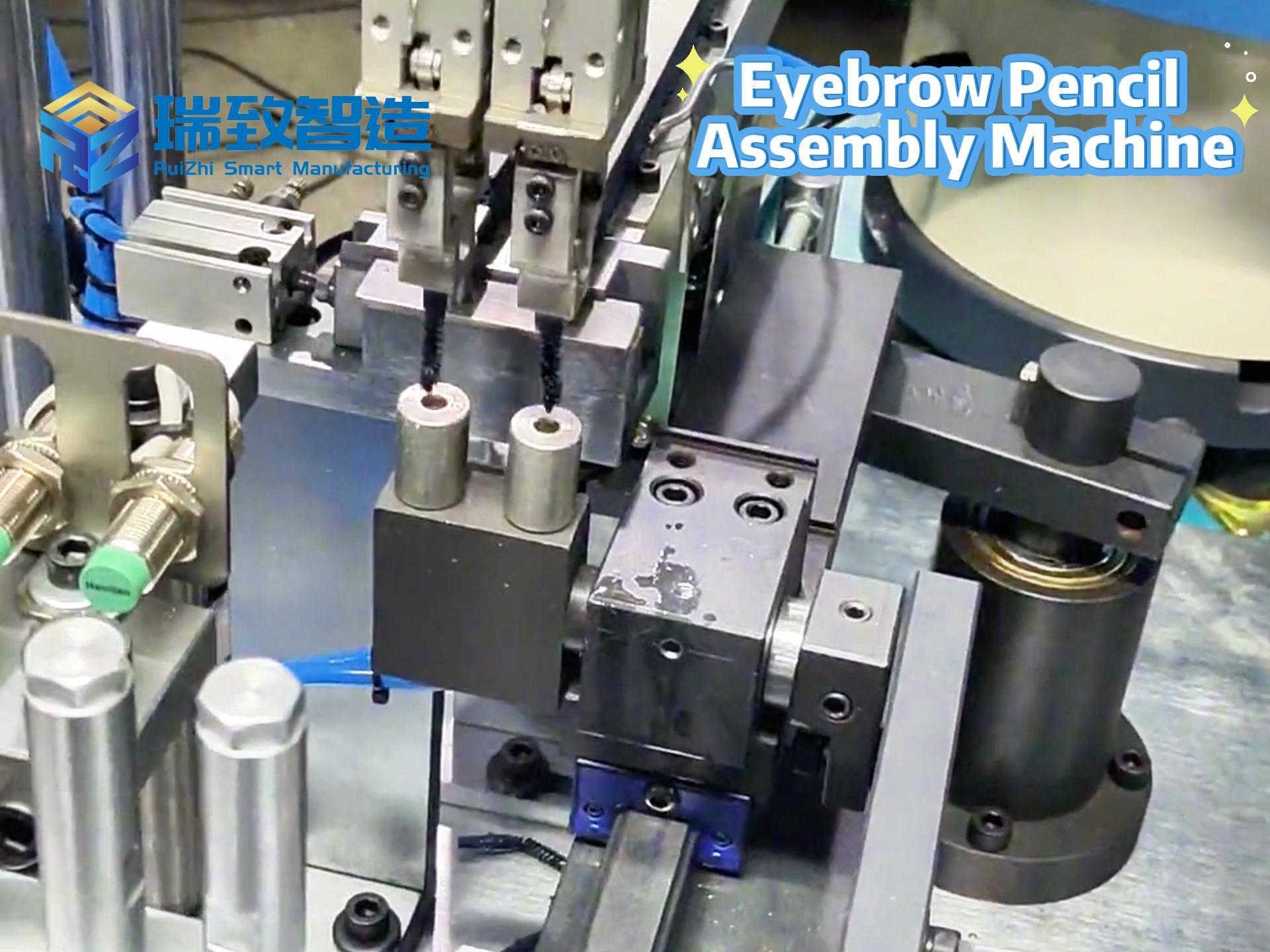

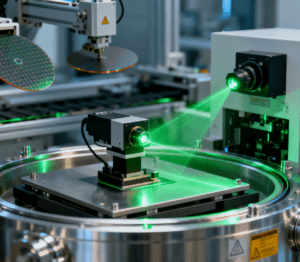

Currently, ultra-precision CNC machining tools stand at the pinnacle in terms of precision. Such machine tools are often applied in specific fields with extremely high precision requirements. For instance, the ultra-precision CNC worktables equipped with lithography machines in the semiconductor chip manufacturing field boast nanometer-level positioning accuracy. When processing chip circuit patterns, even a tiny deviation can lead to a significant decline in the chip’s performance or even render it scrapped. These ultra-precision CNC machines utilize advanced laser interferometry systems to accurately monitor the position of the machine’s moving components in real-time, controlling errors within an extremely small range. Meanwhile, the high-precision aerostatic bearings and linear motor drive technology they adopt effectively reduce mechanical friction and vibration, further enhancing motion precision. Notably, in the subsequent assembly link of semiconductor manufacturing, the 电子元件自动加载组装机, which collaborates with ultra-precision CNC machines, also adheres to rigorous precision standards—it needs to achieve micron-level positioning accuracy when loading and assembling tiny components like chip capacitors and resistors, ensuring that the high-precision machining results of CNC machines are not compromised by assembly deviations.

In the optical manufacturing field, some ultra-precision CNC grinders used for processing high-precision optical lenses and gratings are also paragons of precision. They can control the surface roughness of lenses at the nanometer level and achieve sub-micron or even higher surface shape accuracy. This is attributed to their specially designed high-precision spindles, ultra-precise grinding tools, and advanced processing technology algorithms. Through precise control of parameters such as pressure, speed, and temperature during the grinding process, they achieve the ultimate refinement of the shape and surface quality of optical components.

Enterprise Practice: Precision Breakthroughs by Airey Precision Machinery

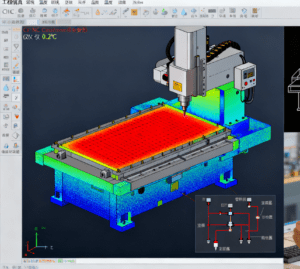

Airey Precision Machinery has made in-depth explorations and outstanding achievements in the field of high-precision CNC machines. The company actively introduces and develops advanced ultra-precision CNC technologies, and its independently developed ultra-precision five-axis machining center demonstrates excellent precision performance in multiple key indicators. This machine tool adopts a high-precision grating ruler feedback system, which can achieve nanometer-level position detection resolution. Combined with an advanced CNC system, it can perform ultra-precision machining of complex 3D curved surfaces. When processing high-precision components in the aerospace field, such as key blades of aero-engines, it can strictly control the contour accuracy, thickness tolerance, and surface quality of the blades, ensuring the efficient and stable operation of the engine. Airey Precision Machinery’s technical team continuously optimizes the machine tool’s structural design and processing technology, improving the rigidity and stability of the machine tool through methods such as finite element analysis, and reducing the impact of thermal deformation and vibration during processing. At the same time, it has accumulated rich experience in tool selection and cutting parameter optimization, further improving processing precision and surface quality.

The Relativity of “Most Precise”: Scenarios Define Precision Core

However, the definition of “most precise” is not absolute; it often depends on specific application scenarios and requirements. Different industries have different focuses on the precision of CNC machines: some prioritize dimensional accuracy, while others focus more on surface roughness or shape accuracy. Moreover, with the continuous development of science and technology, the precision of CNC machines is constantly improving, and new technologies and materials are continuously applied in machine tool manufacturing.

Although it is difficult to determine an absolutely “most precise” CNC machine, ultra-precision CNC machine tools used in fields such as semiconductors and optics are undoubtedly at the forefront of precision. Enterprises like Airey Precision Machinery continue to move forward in the development of high-precision CNC machines through continuous innovation and technological research and development. They provide strong support for meeting the extreme precision needs of different industries and drive the entire manufacturing industry toward higher precision.

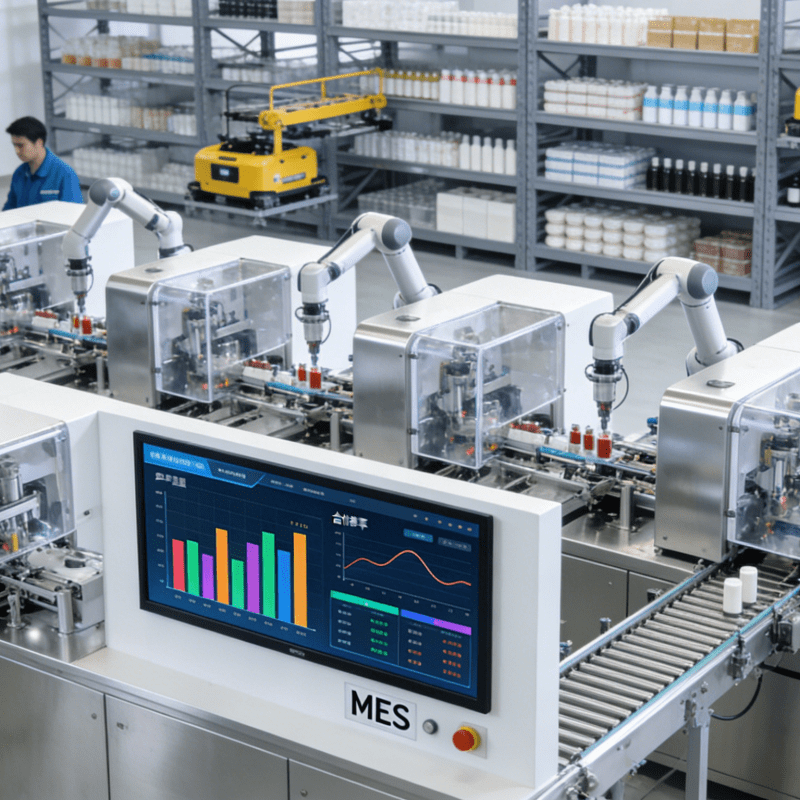

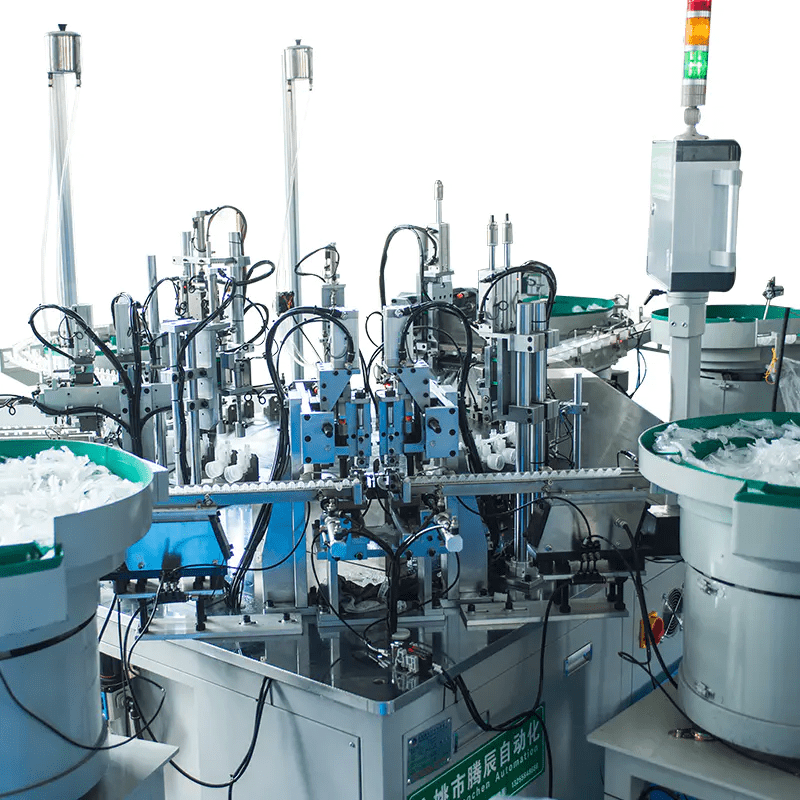

How to choose a multi-component capping assembly machine suitable for your production line?