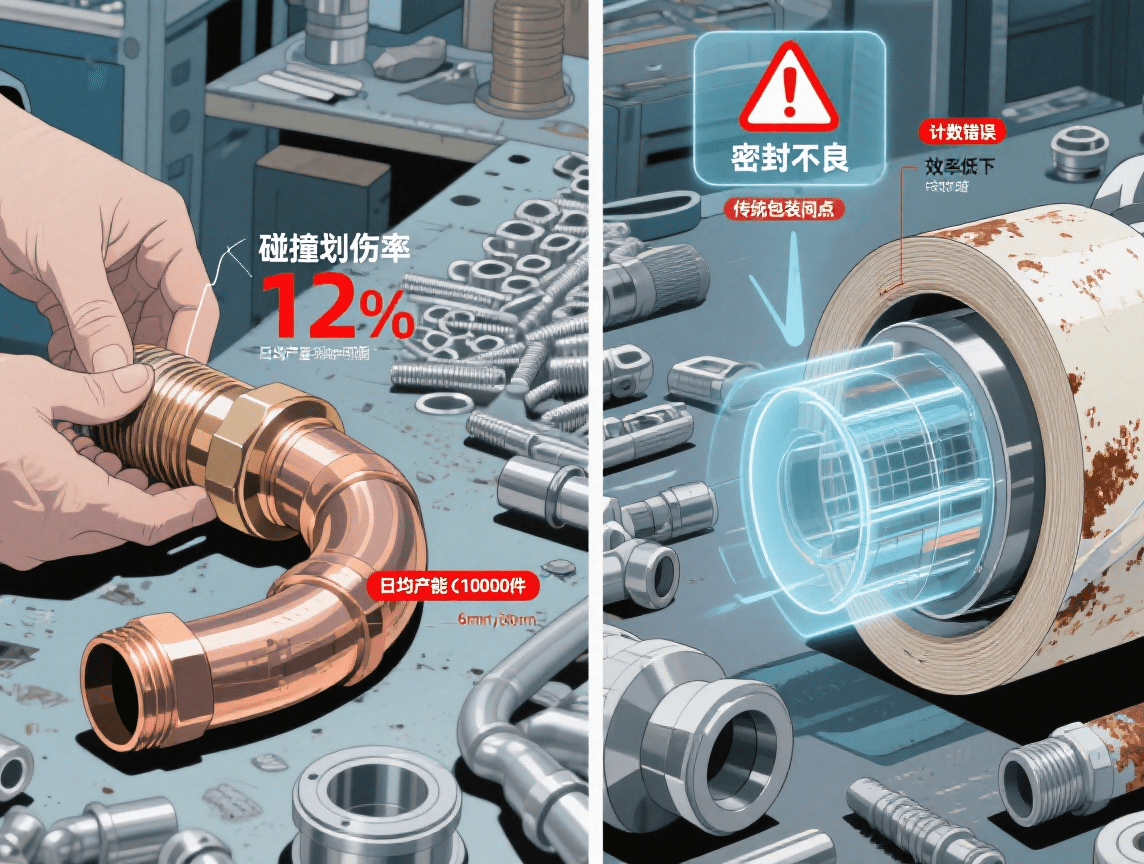

In recent years, with the gradual decline of the demographic dividend, the welding industry, which faces harsh working environments and a scarcity of skilled welders, has been trapped in a transformation dilemma. Against this backdrop, the market demand for welding robots has been growing, and the requirements for the intelligence level of welding robots have […]

In the process of intelligentizing welding robots, the intelligent welding control system, as the “brain” of intelligent welding robots, becomes more valuable as it grows “smarter” and easier to learn. It can reduce enterprise costs, bring better profits, and help enterprises seize the high ground in future competition. Thus, the intelligent welding control system has ushered in a new round of explosive demand.

From the perspective of enterprise layout, although there are relatively few domestic manufacturers involved in intelligent welding control systems, the market pattern has initially taken shape.

According to incomplete statistics from Gaogong Robot, at the Essen Exhibition, which just concluded in late June, nearly 20 enterprises exhibited their intelligent welding robots or workstations, among which about 15+ exhibitors displayed robots equipped with Baichu Electronics’ intelligent welding systems, accounting for a very high proportion. As a leader in the laser cutting control field, Baichu Electronics is now also showing strong market penetration in the intelligent welding field, becoming another “invisible standard configuration”.

Why can Baichu Electronics’ “intelligent welding control system” become the “invisible standard” of the industry?

Undercurrents of Invisible Intelligent Welding Technology Breakthroughs and Changes

With the rapid development of the industry, the disadvantages of traditional teaching robots, which rely on manual teaching, have low efficiency and complex operations, have become prominent. Industrial control technology enterprises represented by Baichu Electronics have started from digital twin, intelligent perception, AI technology and other aspects to reduce operation difficulty, improve welding quality and efficiency, and empower the industry.

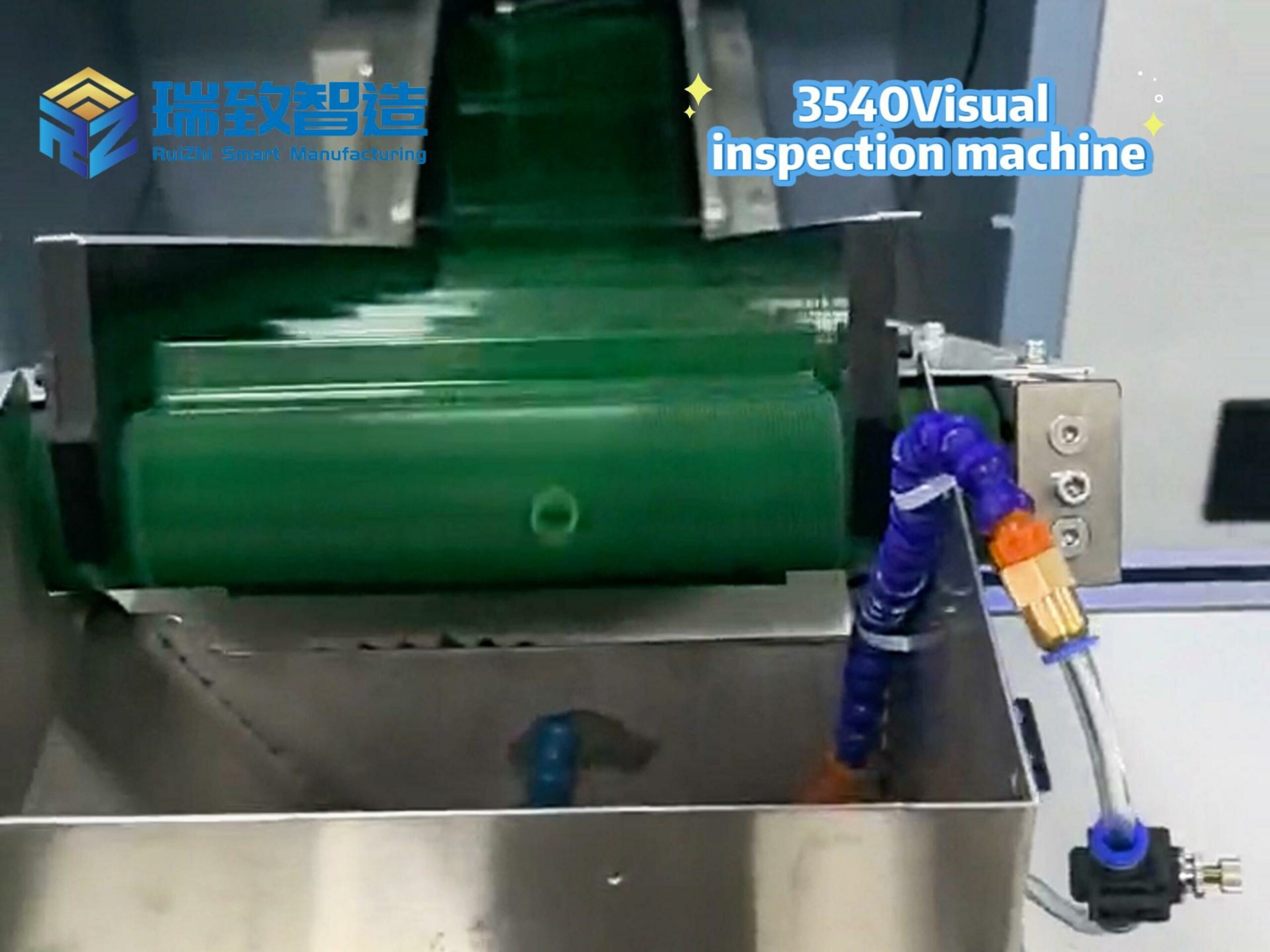

According to data, the intelligent welding control system independently developed by Baichu Electronics mainly involves five core technologies (robot control, graphics, kinematics, intelligent perception, and craftsmanship). The “digital twin system” technical solution created by these five core technologies can not only realize “teaching-free” welding but also has intelligent functions such as anti-collision detection and arc tracking.

Rather than repeating technical jargon, Gaogong Robot prefers to analyze the reasons for Baichu’s market recognition from the user’s perspective. In summary, Baichu’s “intelligence” accurately “targets” users’ pain points:

- It is simple enough to lower the threshold for users: The system can intelligently parse workpiece models, automatically extract weld information, and plan the welding path and posture of the entire workpiece. User feedback shows that it significantly reduces operation and learning costs.

- It is practical enough to cope with complex scenarios: The self-developed vision system combined with arc tracking technology enables the system to adaptively adjust to workpiece assembly errors and deformation, and there are specialized solutions for different industries.

Through exhibition research and data sorting, Gaogong Robot found that Baichu’s intelligent welding system has accumulated extensive customer cases in the application of steel structure welding in industries such as construction, power oil tanks, power towers, ships, bridges, and mechanical equipment, verifying the practicality of its technical solutions.

It is not so much the success of “Baichu Intelligent Welding” as the victory of “adhering to long-termism”.

In fact, what interests Gaogong Robot most about Baichu Electronics is not its various technical highlights in the intelligent welding field or its wide market recognition. Behind the technology and market, Baichu Electronics’ concept of “adhering to long-term development of independent research and development of underlying technologies” seems to be the key to its continuous vitality and ability to navigate through cycles.

Public information shows that Baichu Electronics is one of the first private enterprises in China engaged in the development of complete sets of fiber laser cutting control systems.

Its total R&D and technical personnel account for more than 60%, and in the intelligent welding business, this proportion even exceeds 70%. Continuous R&D investment has enabled it to accumulate solidly in basic technical fields such as graphics, computer vision, robot kinematics, craftsmanship, and control.

It is based on this profound technical foundation that Baichu Electronics has been able to relatively efficiently migrate its core technical capabilities accumulated and verified in the laser cutting field to the new field of intelligent welding.

Industry analysis believes that there are two typical development paths for intelligent welding control systems: one is the rapid iteration school, and the other is the long-termism school. The former quickly enters the market through secondary development based on existing control systems (referred to as “secondary development”), relying on external core technologies for application layer optimization; the latter adheres to full-stack independent research and development to form a technical closed loop. Baichu Electronics has obviously chosen the latter – a path with greater investment and longer cycles, but aiming to build a complete technical closed loop and autonomy.

Industry observations point out that although secondary development can quickly open up the market, with the continuous iteration and upgrading of technology, enterprises will be increasingly constrained by others, facing the triple risks of technology out of control, cost out of control, and market out of control, and are also prone to fall into homogeneous competition. However, once full-stack independent research and development breaks through the core technical barriers, it will form a high competitive threshold.

Facts have proved that Baichu Electronics’ choice is highly strategic. As mentioned earlier, Baichu Electronics’ intelligent welding control system has become the “default option” for most robot enterprises in the market. In a sense, this is also a typical achievement and strong proof of Baichu Electronics’ technology migration strategy.

What is more noteworthy is that the potential versatility of Baichu Electronics’ underlying technologies is gradually emerging. Gaogong Robot noticed that at this Essen Exhibition, Baichu’s “robot flame beveling control system” became another example of its technical capabilities.

This system also realizes the automatic processing of complex cutting paths based on its core motion control algorithms and intelligent planning capabilities. This reflects that Baichu’s underlying technology platform has strong transferability and scalability. Once it overcomes the “thick wall” of “underlying technology”, the boundary of the enterprise’s technical application will be greatly expanded, and the development ceiling will be unprecedentedly improved.

It can be seen that Baichu Electronics is still actively promoting the expansion and application of intelligent technologies, digging deep into other industries and processes related to welding technology, so that intelligent robot technologies can be applied to the automation processes of more industries.

From a laser leader to a welding giant, and now quickly entering the field of robot flame cutting, Baichu Electronics has proved with practical actions that enterprises adhering to independent research and development and innovation of underlying technologies will eventually win the double compound interest of the market and time.

Finally, the ultimate goal of promoting welding intelligence lies in three things: making processing simpler, making workers healthier, and making bosses more profitable. For workers, they can be liberated from harsh environments; for enterprises, it can improve efficiency and quality and alleviate the problem of labor shortage.

Baichu obviously has a higher intelligent vision and goal for the entire industry – committed to endowing robots with stronger perception, understanding, and execution capabilities, and providing excellent intelligent robot solutions for smart factories.

The core of this vision is to enable robots to have “thinking ability” – no longer machines that passively execute instructions, but can actively understand tasks, perceive the environment, and adjust strategies, truly realizing the intelligent upgrade that serves people. Baichu Electronics’ persistent pursuit and extensive practice of “intelligence” are reshaping the development pattern of the entire robot control field. This is the requirement of the times and the inevitable trend of industry progress.