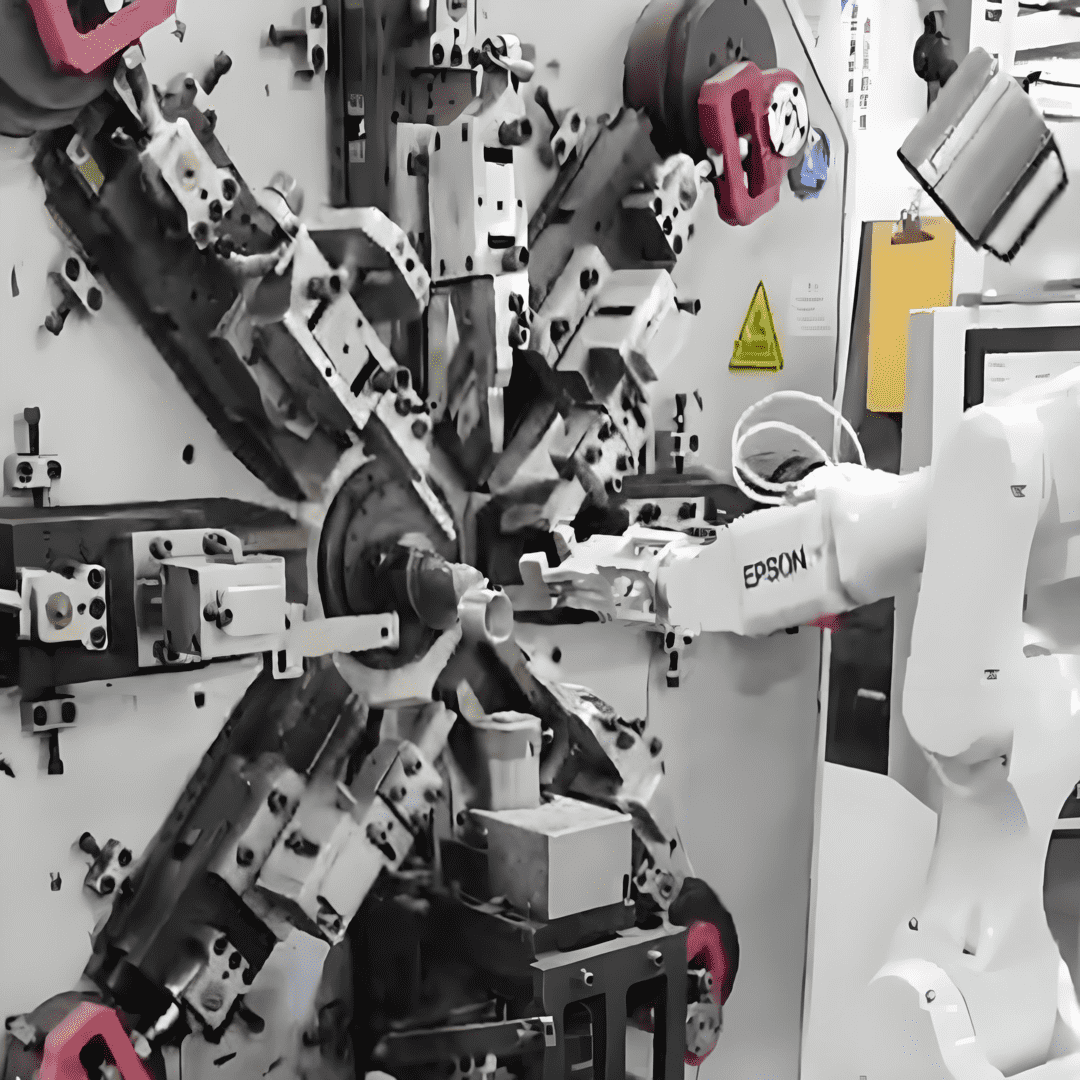

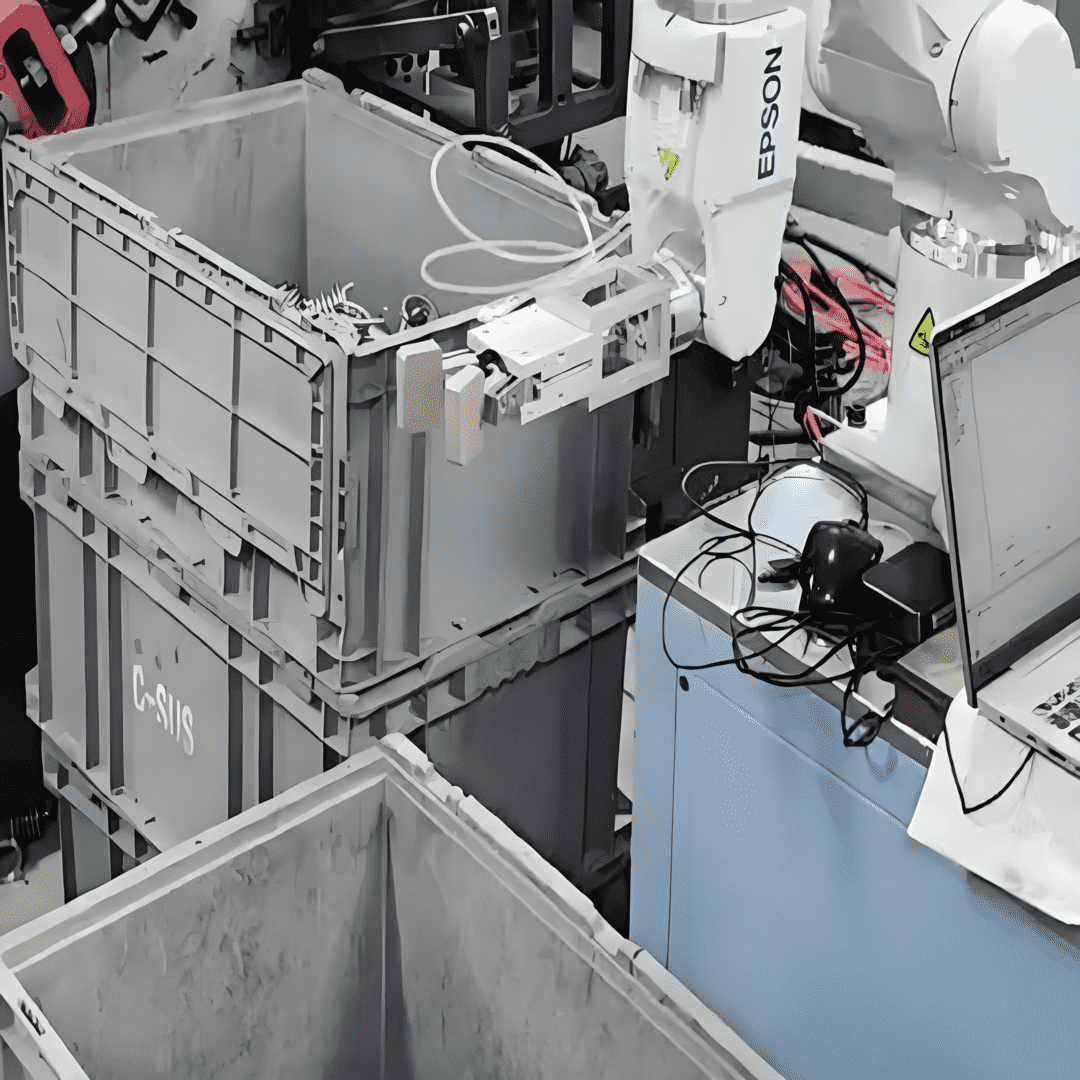

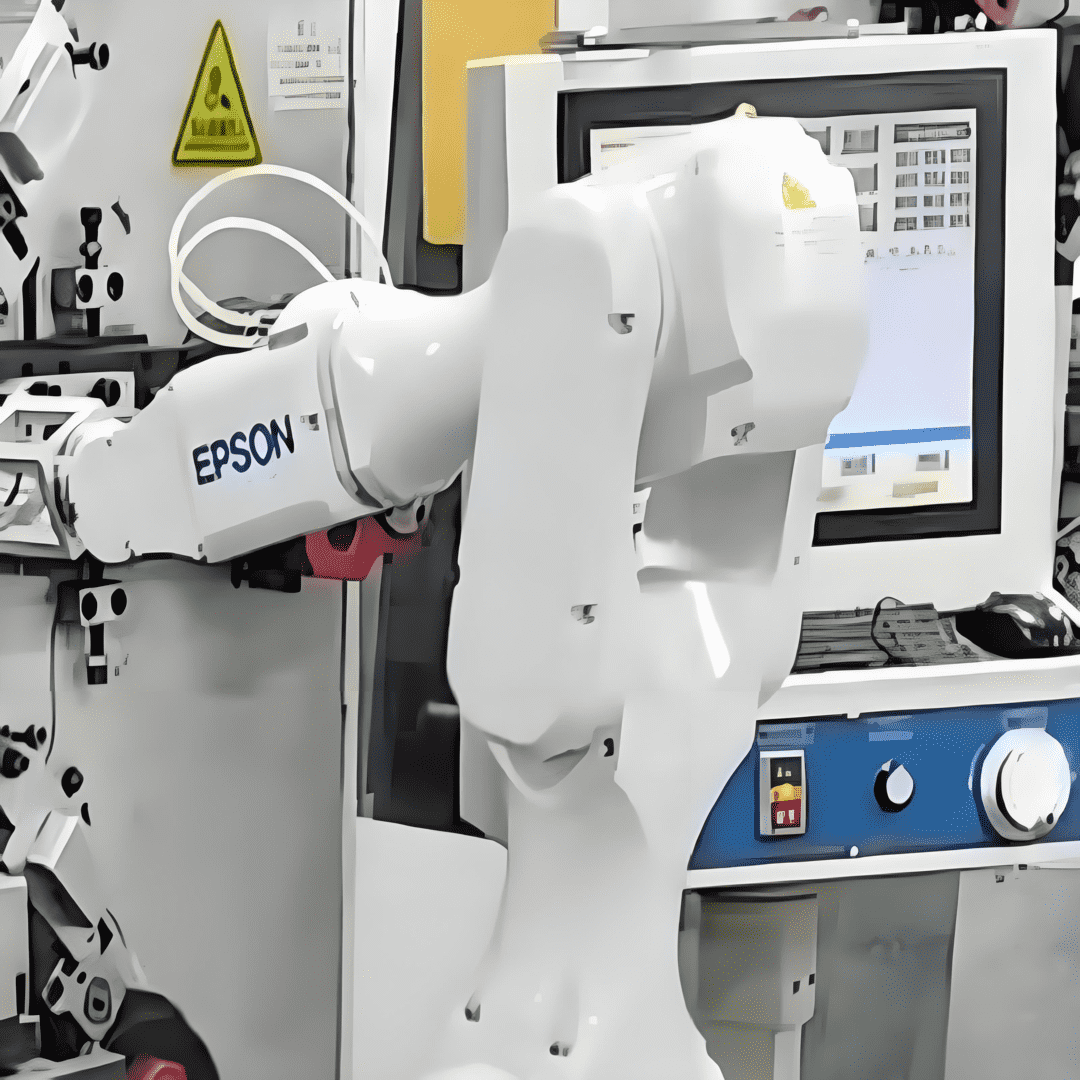

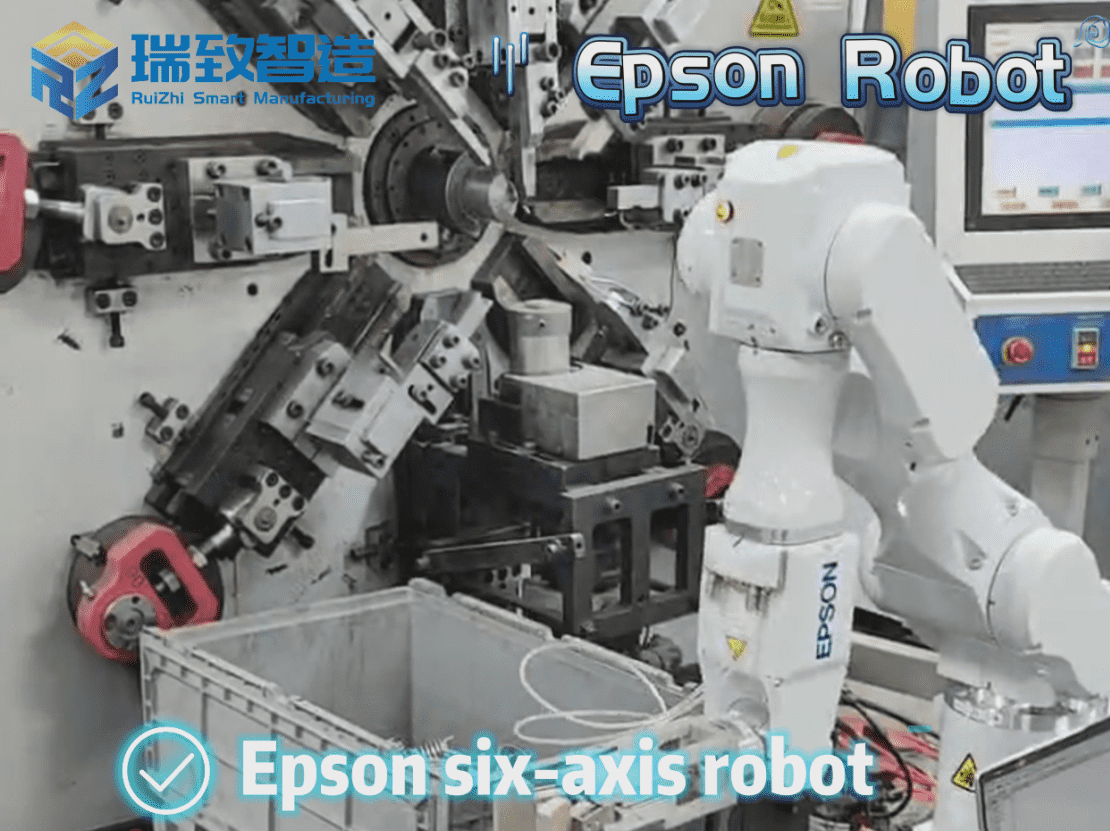

六轴机器人弹簧拾取与放置系统

The AI-enhanced 4-Axis Robotic Frame Pick-up System uses 4-axis robotic arms with vision guidance to automate frame handling, ensuring precise picking/placing with ±1mm accuracy and a 99.8%+ success rate. It reduces labor by 60-75%, achieves ROI in 12-18 months, and boosts daily handling capacity to thousands of frames. Supporting tool-less quick changeovers for multi-type frames, it minimizes manual errors and damage by 15%, integrates with smart production lines, and enhances efficiency in high-mix manufacturing via adaptive path planning for stable, rapid frame transportation.

| Components Qty | 9 parts |

| Cycle Time | 5.3 sec/pc |

| Pneumatic Parts | SMC |

| OEE | 80% |

| First Pass Yield | 98% |

| Standard Parts Brand | Panasonic, Mitsubishi, SMC, Keyence, Omron |

| Requested Operators | 2 operators |

| Certificate | CE |

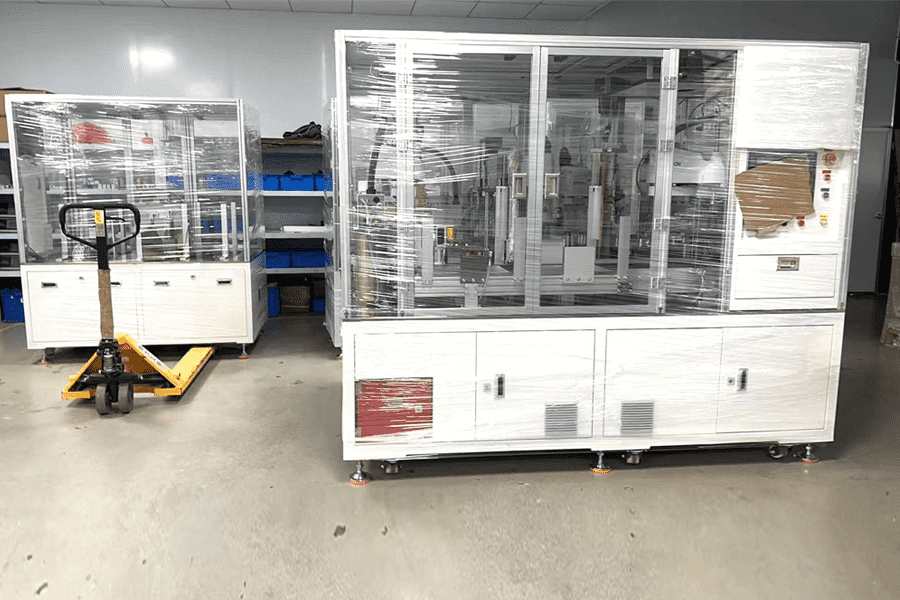

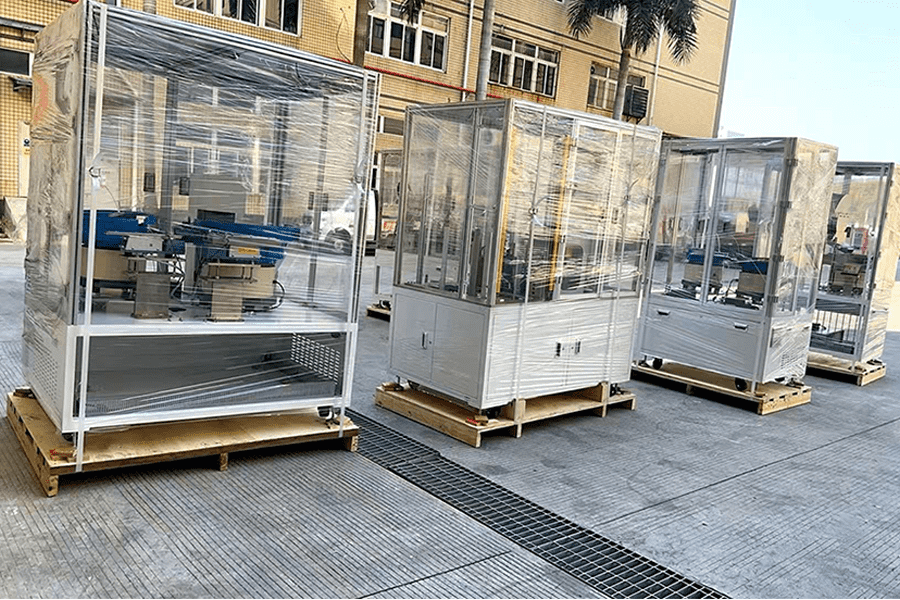

After the equipment has been assembled and debugged, we will select suitable packaging materials to properly protect the equipment. This will effectively safeguard it against impacts, moisture, and ensure it is firmly secured, guaranteeing that the equipment arrives at its destination intact.

● On site installation, debugging, training and mass production follow up.

● 1 year Warranty from date of shipment, lifetime maintenance service.

● Respond to defects within 4 hours.

● 12 hours for overseas customers by telephone or mail.

● Supply remote services by smart glass, team viewer, Teams and camera.

1. The technical training described below is free technical training, and no additional fees are charged. The technical training consists of the project’s on site general manager, mechanical engineer and electrical engineer, who are responsible for implementing the entire training plan.

2. The whole process of installation from the installation to the commissioning is carried out by the expert group and the production technology, equipment management and production operators designated by the customer. At the same time, the expert group is responsible for technical guidance to the customer’s technical staff throughout the implementation process. Training with technical points, including:

a. Equipment system principle and operation method, maintenance.

b. Equipment operation and debugging, parameter setting.

c. Operation and application of the software.

d. Operating procedures and precautions for the equipment.

e. Safety protection measures for various action agencies.

f. Maintenance of electrical systems and mechanical parts.

g. How to make correct judgment, analysis and how to troubleshoot when the equipment fails.

h. Solutions to possible dangerous situations.