Pipe threads are the core structure for the connection of pipeline systems, and their machining quality directly determines the tightness, pressure-bearing capacity and service life of pipelines. Against the backdrop of the manufacturing industry’s transformation towards precision and high efficiency, precision machining of pipe threads, with its standardized and automated technical characteristics, has gradually become the mainstream choice for pipe thread production across various industries. This paper objectively analyzes the core value of pipe thread precision machining from three dimensions: technical definition, application scenarios and process advantages.

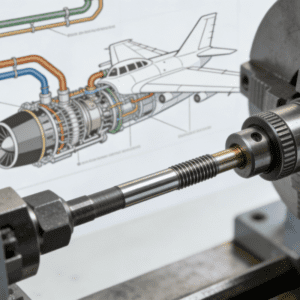

Pipe thread precision machining refers to a technical method that leverages computer numerical control systems (intelligent manufacturing) combined with specialized precision machining equipment to convert the design parameters of pipe threads into digital programs, thus achieving the automated machining of key indicators such as thread profile, pitch and taper. Its core principle is to replace manual operation with pre-set programs to drive machine tools to complete machining processes such as turning and milling, with the system precisely controlling the tool movement trajectory and machining parameters throughout the entire process.

Different from traditional pipe thread machining, this technology does not rely on the experience-based adjustments of operators; instead, it ensures the standardization of the machining process through digital modeling and program optimization. Machining equipment is usually equipped with high-precision detection modules, which can provide real-time feedback on machining data and timely correct errors caused by tool wear, temperature variations and other factors, ultimately achieving precise control over the dimensional accuracy and geometric tolerances of pipe threads. In essence, it is an in-depth integration of digital technology and mechanical machining processes. It not only meets the core functional requirements of pipe thread connection, but also breaks through the efficiency and precision limitations of traditional machining processes.

Main Application Fields of Pipe Thread Precision Machining

With its superior precision and stability, pipe thread precision machining has been widely applied in various industries with stringent requirements for pipeline connections, serving as a crucial technical support for ensuring the safe operation of equipment.

Petrochemical Industry: Pipe threads used in the oil and natural gas extraction and transportation pipelines are required to withstand harsh working conditions such as high pressure and corrosion. Precision-machined pipe threads enable accurate sealing to prevent medium leakage, meeting the connection requirements of scenarios such as long-distance oil and gas transportation and chemical reaction equipment.

Construction Machinery Industry: The connection reliability of pipe threads in the hydraulic systems and fuel pipelines of construction machinery such as excavators and loaders directly affects equipment operation. Precision machining technology ensures thread consistency, reduces the risk of loosening under vibration and high-pressure environments, and guarantees the stable operation of construction machinery.

Aerospace and Shipbuilding Industry: Pipeline connections in aircraft fuel pipelines and ship power systems impose extremely high requirements for lightweight design and ultra-high precision of pipe threads. Pipe thread precision machining enables the accurate machining of micro-sized threads while meeting the machining requirements of high-strength materials, making it adaptable to the extreme operating environments of aerospace and marine vessels.

Plumbing, Sanitary Ware and Construction Industry: Pipe threads in the water supply and drainage pipelines, heating systems of civil buildings, as well as the connecting pipelines of sanitary ware equipment are required to have excellent tightness and easy installation. Precision-machined pipe threads feature unified dimensions, eliminating the need for repeated adjustments during assembly, which improves construction efficiency and connection reliability.

Energy Equipment and Precision Instruments Industry: The machining precision of pipe threads in the hydraulic pipelines of wind power equipment, cooling pipelines of nuclear power systems and fluid delivery pipelines of precision instruments directly impacts equipment performance. Precision machining technology can achieve micron-level precision control, satisfying the high reliability requirements of energy equipment and precision instruments.

Core Advantages of Pipe Thread Precision Machining Compared with Traditional Processes

Compared with traditional pipe thread machining processes (e.g., conventional lathe machining and manual grinding), pipe thread precision machining is not a simple technological replacement, but a comprehensive upgrade based on functional realization. Its core advantages are mainly reflected in the following aspects:

Higher machining precision and superior sealing performance: Traditional machining relies on manual operation, which is prone to problems such as pitch deviation and irregular thread profile, thus compromising sealing effectiveness. Through precise program control, precision machining can control thread dimensional errors at the micron level, producing full and uniform thread profiles, which greatly improves the sealing performance and pressure-bearing capacity of pipeline connections.

Improved production efficiency, suitable for batch production: Traditional machining requires repeated manual adjustment of tool and workpiece positions, resulting in long changeover cycles. Precision machining enables rapid switching of machining specifications via pre-set programs, and in combination with automated loading and unloading systems and the 注塑件自动化组装系统带自动装载功能, it can form a seamless integrated production line from pipe thread machining to injection-molded accessory assembly, further shortening the overall production cycle. Especially in batch production, it can maintain stable output efficiency and significantly increase the per-unit-time output.

Strong product consistency and excellent assembly adaptability: Affected by the skill differences of operators, traditional processes lead to large dimensional fluctuations of pipe threads in the same batch, often causing assembly compatibility issues. Precision machining realizes standardized production, ensuring highly consistent dimensions and geometric tolerances of products in the same batch, without the need for additional grinding and adjustment, which reduces assembly difficulty and rework rates.

High process flexibility, adaptable to complex requirements: To meet complex machining demands such as non-standard pipe threads and special taper threads, traditional processes require customized special tooling, which incurs high costs and long lead times. Precision machining only requires program modification to realize the machining of pipe threads with different specifications and types, eliminating the need for frequent tooling replacement, and flexibly adapting to the production needs of multi-variety and small-batch production.

Lower comprehensive cost and remarkable long-term benefits: Precision machining optimizes cutting paths to reduce material waste and improve material utilization rate. Meanwhile, automated machining cuts labor costs and the reject rate caused by human errors. Although the initial equipment investment is relatively high, it can effectively reduce the comprehensive production cost in the long run, making it particularly suitable for large-scale production scenarios.

The popularization of pipe thread precision machining technology is an inevitable result of the manufacturing industry’s pursuit of precision and high efficiency. It not only retains the core function of pipe thread connection, but also compensates for the deficiencies of traditional processes through digital means, providing more reliable and efficient machining solutions for pipeline systems in various industries. From industrial production to civil construction, from precision equipment to energy facilities, pipe thread precision machining is supporting the stable operation and iterative upgrading of various types of equipment with its unique technical advantages.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine