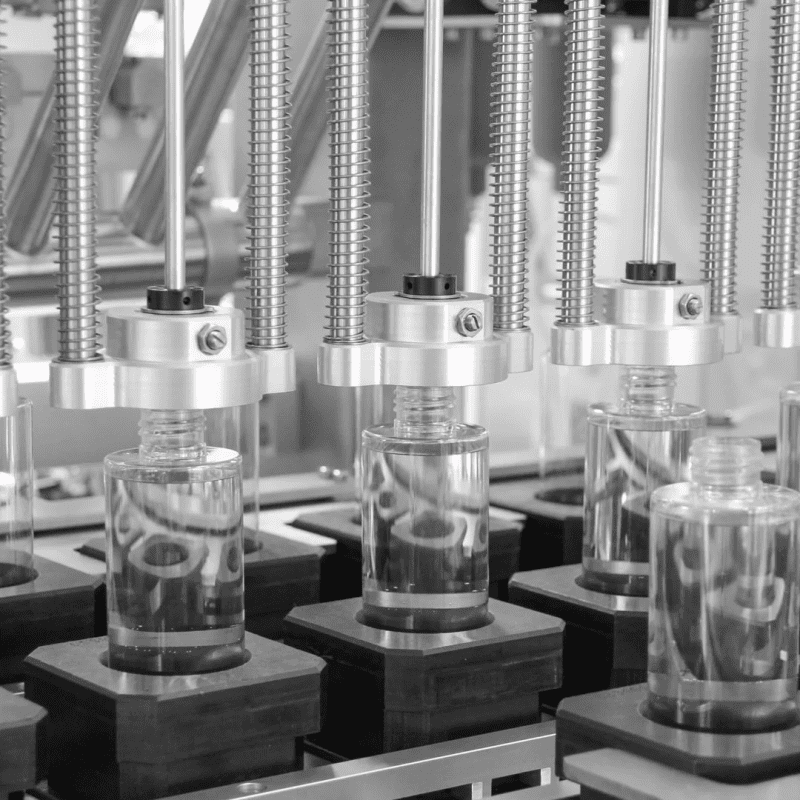

Perfume sprayers are core components of fragrance products, and their assembly quality directly affects product sealing, usability, and brand reputation. However, many cosmetics and perfume manufacturers face stubborn pain points in sprayer assembly—low efficiency, high error rates, and poor adaptability to diverse specifications. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has developed high-performance perfume sprayer assembly machines, targeting these pain points to help enterprises optimize production and reduce operational burdens.

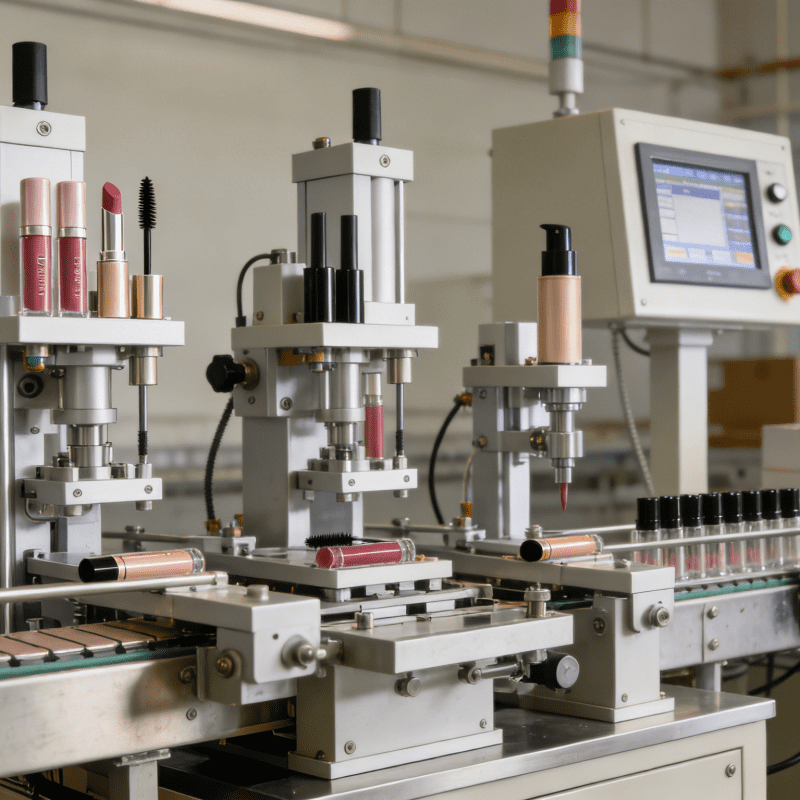

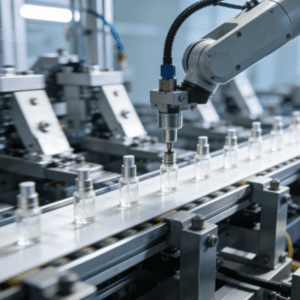

Solve Low Efficiency Pain Points with Automated Assembly

Manual assembly of perfume sprayers involves small components like pumps, nozzles, and caps, which is time-consuming and labor-intensive. A single worker can only assemble 40-60 units per minute, and fatigue easily leads to slower speeds. Ruizhi’s perfume sprayer assembly machine adopts automatic feeding, positioning, and assembly technology, reaching 120-160 units per minute—3 times faster than manual work. It supports 24/7 uninterrupted operation, significantly improving production efficiency and helping enterprises meet large-order demands quickly.

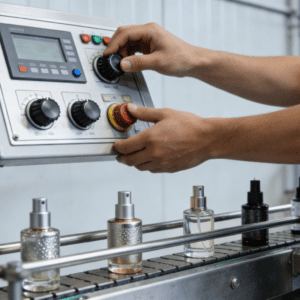

Eliminate High Defect Rates Caused by Manual Errors

Perfume sprayers require precise assembly to avoid leakage, and manual operation is prone to errors such as misaligned nozzles, loose caps, or incomplete pump installation, resulting in high defect rates and material waste. Our machine is equipped with high-precision detection sensors and intelligent control systems, which automatically identify and reject defective products in real time. This reduces the defect rate to nearly zero, saves raw material costs, and ensures consistent product quality.

Adapt to Diverse Specifications with Non-Standard Customization

The perfume market features diverse sprayer styles, sizes, and assembly processes, and standard machines often fail to adapt to these changes. Ruizhi Intelligent Manufacturing focuses on non-standard customization—we design personalized assembly solutions according to your sprayer specifications, assembly steps, and output requirements. Whether it’s a small-batch custom sprayer or a large-scale standard model, our machine can be quickly adjusted, eliminating the trouble of replacing equipment and reducing transformation costs.

In conclusion, Ruizhi’s perfume sprayer assembly machine precisely solves the core pain points of perfume manufacturers. With automated efficiency, high-precision quality control, and flexible non-standard customization, we help you reduce costs, improve efficiency, and gain a competitive edge in the fierce fragrance market.