Perfume sprayers are core components of fragrance and cosmetic products, requiring strict control over airtightness, assembly precision, and appearance consistency. Manual assembly often fails to meet cosmetic-grade standards, with low efficiency and high defect rates. Ruizhi Intelligent Manufacturing’s perfume sprayer assembly machine is tailored for perfume & cosmetic factories, integrating non-standard customization, high precision, and efficiency to solve industry production pain points.

Non-Standard Customization for Diverse Perfume Sprayer Specs

Cosmetic and perfume factories face diverse sprayer specifications, from mini travel-size to large-capacity bottles, with materials ranging from aluminum to plastic. Ruizhi’s modular design adapts to sprayers of different diameters (8-25mm), nozzle types, and material combinations. We customize clamping fixtures, assembly processes, and detection standards for special needs, such as anti-corrosion sprayers or luxury perfume atomizers. Quick-change parameter settings shorten product changeover time to 12 minutes, perfectly matching small-batch, multi-spec cosmetic production.

Core Performance Meeting Cosmetic-Grade Requirements

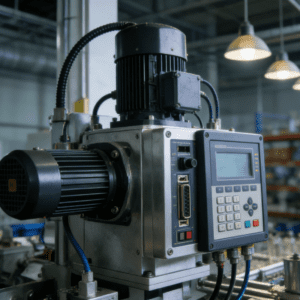

The machine adopts PLC control and high-precision servo motors, achieving assembly accuracy within ±0.02mm and ensuring tight fitting between nozzles, pumps, and caps. Equipped with automatic airtightness detection, it screens unqualified products in real time, pushing the qualified rate to 99.6%+. With multi-station synchronous operation, the capacity reaches 4,000-6,500 pieces per hour, 10 times that of manual work. The closed structure avoids dust contamination, complying with GMP and cosmetic industry hygiene standards.

One-Stop Service Empowering Stable Production

Ruizhi provides full-cycle support for perfume & cosmetic factories. Before delivery, we conduct targeted debugging based on factory production lines; after-sales, we offer on-site training, maintenance, and spare parts supply. The machine is made of 304 stainless steel, corrosion-resistant and easy to clean, reducing daily maintenance costs. For small and medium-sized factories, we optimize the machine’s footprint and energy consumption, balancing efficiency and cost control.

Ruizhi Intelligent Manufacturing focuses on non-standard automation solutions for the cosmetic industry. Our perfume sprayer assembly machine helps factories reduce labor costs by over 80%, improve production stability, and enhance product competitiveness. It has become a reliable partner for perfume & cosmetic enterprises pursuing high-quality and efficient production.

Assembly line for mass production by artificial intelligence