As one of the most watched professional exhibitions under the China International Industry Fair (referred to as “CIIF”), the Industrial Automation Show (referred to as “IAS”) has a glorious history and successful experience of 17 years since its establishment. It is an important display platform for advanced manufacturing, actively playing a supporting role in strengthening and supplementing industrial chains, driving application scenarios, integrating technologies, and promoting domestic substitution. This year, IAS has gathered many outstanding enterprises at home and abroad, strengthened its role in empowering high-end manufacturing, and built an innovative application platform for AI and intelligent agents.

Cutting-Edge Technologies Unveil a New Pattern of Intelligent Manufacturing

At each IAS, exhibitors showcase a constant stream of new products, jointly outlining the future development blueprint of the industry. Leading domestic and foreign enterprises bring a variety of globally premiered, China-premiered, independently developed, and innovative products and solutions, presenting the most cutting-edge industrial technologies and applications through immersive interactive experiences.

Huawei-Phoenix Contact OICT Hyper-Converged Flexible Smart Manufacturing Demonstration Line

This demonstration line relies on Huawei’s solid ICT capability base and takes Phoenix Contact’s open control platform PLCnext virtualization control technology as the core. It has created a native flexible production line application based on Kunpeng\QSemOS\advanced industrial network + Virtual PLCnext Control, realizing factory wirelessization, PLC centralization, and production line flexibility.

Phoenix Contact provides a rich portfolio of innovative products including PLCnext technology, HMI devices, industrial connectors, terminal blocks, and QUINT power products, as well as professional technical support and customized solutions. Huawei and Phoenix Contact will work together to promote the in-depth and practical application of OICT integration, jointly build an open and universal automation architecture, and drive the comprehensive development of the industrial chain.

Omron Intelligent Production Management Platform

Independently developed by Omron, the intelligent production management platform includes application modules such as data collection, production management, quality management, equipment management, and energy management. By leveraging software technology and advanced algorithms, it can target four areas of cost reduction and efficiency improvement for enterprises, creating intelligent solutions suitable for various manufacturing sites.

The platform features strong flexibility and can be customized and developed according to the actual needs of different users. In addition, the intelligent production management platform can be combined with automated hardware products to provide overall solutions. Omron hopes to integrate advanced technologies such as automation + informatization + intelligence to empower manufacturing enterprises in cost reduction and efficiency improvement, and work with customers to create a bright future for China’s manufacturing industry!

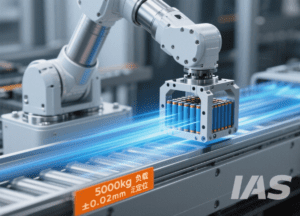

Bosch Rexroth Challenges Traditional Conveyance—FTS Breaks Through Production Efficiency Limits

As early as 2005, Bosch Rexroth launched magnetic levitation conveying technology. After nearly 20 years of market verification, the FTS flexible conveying system has occupied an important position in the high-end transmission line market with its advantages of high flexibility, large load capacity, high speed, and precise positioning. FTS is specially designed for in-plant material transportation, with ultra-high load capacity—each mover can carry up to 5,000 kg, while achieving a maximum running speed of 2.5m/s and positioning accuracy of ±0.02mm, setting an industry technical benchmark.

Facing the explosive growth of the lithium battery industry, Bosch Rexroth has deeply insight into customers’ differentiated application scenarios and business needs, and developed a variety of conveying system solutions with high speed and precision, heavy load, and seamless connection with traditional conveying lines. From cell assembly to the entire Pack process, the FTS flexible conveying system is fully empowering lithium battery intelligent manufacturing with extreme flexibility and stability.

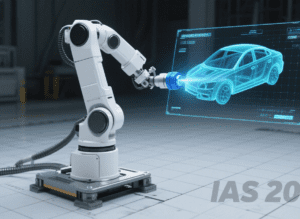

Hexagon PRESTO Automated Measurement System

Developed by Hexagon specifically for automated measurement of large and medium-sized components, it can be widely used in the rapid inspection of large automotive structural parts. Combining advanced optical measurement technology with efficient robotic measurement technology, it can quickly and accurately complete 3D digitization and dimensional measurement tasks for various components.

PRESTO is also a future-oriented measurement system, featuring high scalability, seamless integration, and strong adaptability, which can meet the changing needs of modern manufacturing, helping customers effectively reduce measurement time and simplify work processes.

Baumer OM60 Laser Distance Sensor

Technical Parameters:

Excellent accuracy: linear error as low as ±3 μm, repeatability up to 0.12 μm

Highly flexible and reliable solution, offering different measurement ranges, with a maximum of 1000 mm

Measurement frequency up to 3.3 kHz

Rich signal types: supporting analog, IO-Link, or RS485 output

Core Features:

Superior precision: ultra-fine line spot technology for stable detection of difficult surfaces such as bright metal and textured wood;

Innovative design: optimized mechanical and thermal stability, compact and robust;

Intelligent and easy to use: supports IO-Link/Modbus RTU protocols, and parameters can be intuitively configured via Baumer sensor suite software.

Application Scenarios:

Suitable for high-precision industrial inspection, such as automotive parts positioning, electronic product quality control, robot precision operations, and thickness measurement, meeting stringent quality inspection requirements.

FeasyBeasy FL7 Series PLC

The FL7 series PLC is a small motion control PLC independently developed by FeasyBeasy, targeting complex mechanical automation and multi-axis motion control applications. It has built-in high-speed pulse input/output capabilities and supports multiple interpolation and electronic cam algorithms. Based on standard PLCopen motion control instructions and combined with the independent FSU platform, it can build a flexible and efficient motion control system.

Equipped with an engineering encryption mechanism, it fully protects intellectual property security. It also supports rapid conversion of multi-brand PLC projects, effectively reducing replacement costs. Adopting a blade-type structure design, it significantly saves installation space in electrical control cabinets, and is widely applicable to high-speed multi-axis synchronous control scenarios such as packaging, printing, robotics, and flying shear/following shear.

Automatic material arranging and packaging equipment has also become one of the highlights of this exhibition. Integrating machine vision and multi-axis collaborative technology, it can automatically sort, orient, and package irregular, multi-specification small parts (such as electronic connectors and hardware accessories). By adaptively adjusting material arranging speed and packaging film tension, it can increase the hourly material arranging and packaging efficiency to over 2000 pieces, with a stable packaging qualification rate of 99.9%, providing flexible solutions for small-batch and multi-variety production in industries such as 3C and automotive parts.

Drawing a New Blueprint for the Future of Intelligent Manufacturing

At this year’s IAS, over 650 high-quality domestic and foreign automation enterprises will gather in the 65,000-square-meter exhibition area to showcase core components of high-end equipment and innovative solutions, presenting new industry hotspots and application trends.

136 specialized, sophisticated, distinctive, and novel enterprises are rooted in the soil of innovation; 36 national-level “little giant” enterprises forge the backbone of technology; 240 high-tech pioneers and 32 gazelle enterprises resonate in harmony. With hard-core technologies as bricks, they are laying a solid foundation for industrial upgrading in the ecological blueprint of IAS 2025. It not only builds a platform for exchanges and cooperation between upstream and downstream industries but also outlines a clear blueprint for the future development of intelligent manufacturing, leading the industry towards a new journey of high-quality, digital, and intelligent development!

Examples of Robot Automatic Assembly Lines

Advantages of Artificial Intelligence Automatic Assembly Lines