This article explores the application of various surface finishing processes in the intelligent processing of metal and plastic parts. The selection of these surface treatments not only affects product quality and appearance but also directly responds to diverse market demands. Based on the characteristics of different materials, technologies such as spraying, anodizing, and electroplating each have unique advantages that effectively improve the durability and aesthetics of parts. In response to the growing demand for customization in the market, manufacturers can flexibly apply these processes to meet consumers’ pursuit of personalized products. By choosing the right surface treatment method, enterprises can enhance product competitiveness and better respond to market challenges.

Exploring the Advantages of Various Surface Treatment Processes in Intelligent Processing

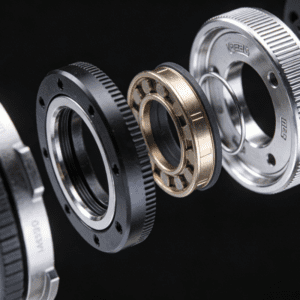

Surface treatment processes play a vital role in intelligent processing. They not only improve the corrosion resistance and wear resistance of metal and plastic parts but also enhance appearance to meet customers’ quality requirements. For example, spraying technology forms a uniform protective layer, making products more attractive while preventing oxidation and friction damage. Anodizing provides aluminum parts with excellent corrosion resistance and a wide range of color options, suitable for diverse applications. In addition, electroplating helps improve the electrical conductivity of parts, making it ideal for electronic products. With such a variety of surface treatment options, enterprises can make the best decisions according to specific needs, thereby enhancing competitiveness and better satisfying market demand.

How Intelligent Processing of Metal and Plastic Parts Adapts to Diverse Market Demands

In modern manufacturing, the intelligent processing of metal and plastic parts requires rapid responses to market changes. This requires producers to continuously innovate to meet the needs of different customers. For metal parts, surface treatments such as anodizing and electroplating can improve corrosion resistance and appearance. For plastic parts, spraying and coating technologies not only enhance appearance but also strengthen product performance. As consumers increasingly pursue personalized and customized products, enterprises must flexibly adjust production processes to launch various types of products in a short time. This adaptability helps enterprises gain a foothold in the highly competitive market while meeting customers’ high standards for quality and design.

Performance for Different Materials: Application Analysis of Spraying, Anodizing and Electroplating

In intelligent processing, spraying, anodizing, and electroplating are common surface treatment technologies suitable for different materials. Spraying effectively improves the appearance of plastic and metal parts, offers various color options, and enhances wear resistance. Anodizing is mainly used for aluminum materials, forming a protective layer through electrolytic treatment that increases surface hardness and prevents corrosion. For metals such as copper and nickel, electroplating is an excellent choice, improving conductivity, corrosion resistance, and appearance. Choosing the right surface process not only enhances part performance but also meets customers’ different requirements for appearance and quality, strengthening market competitiveness.

A Guide to Surface Process Selection for Improving Product Quality and Appearance

In intelligent processing, surface finishing is a key factor in improving product quality and appearance. Common spraying technology adds color and protective layers to metal and plastic parts, improves wear resistance, and achieves various effects such as matte, glossy, or metallic finishes. Anodizing is especially suitable for aluminum, enhancing corrosion resistance and providing diverse color options, ideal for products that require both aesthetics and functionality. Electroplating deposits a metal layer onto the substrate, boosting corrosion resistance and conductivity, and is widely used in automotive parts and electronic equipment. According to the characteristics of different materials and market demands, enterprises should flexibly select these surface treatment processes to improve overall product competitiveness and meet customers’ diverse aesthetic and functional requirements.

Various surface processes provide strong support for the production of metal and plastic parts in intelligent processing. They not only improve the durability and visual appeal of parts but also satisfy different market needs. As customers’ expectations for personalized and high-quality products continue to rise, manufacturers need to flexibly apply these processes. For instance, spraying adds color and protection to various materials, while anodizing improves the corrosion resistance of aluminum parts. Electroplating excels in enhancing conductivity and appearance. Therefore, choosing the appropriate surface treatment method will help enterprises better adapt to market changes and improve their competitive advantages.