Recently, Chinese shipyards have reached important milestones in multiple multipurpose heavy-lift vessel construction and repair projects, making significant progress in construction efficiency, technological upgrading, and maintenance services. Taizhou Port...

Taizhou Port Shipbuilding Delivers the Fourth 62,000 DWT Multipurpose Heavy-Lift Vessel

Recently, Jiangsu Taizhou Port Shipbuilding Co., Ltd. held a naming and delivery ceremony for the “CL FREEDOM”, the fourth 62,000 DWT multipurpose heavy-lift vessel built for Pushang Shipping (Hong Kong) Co., Ltd.

The “CL FREEDOM” is the fourth 62,000 DWT multipurpose heavy-lift vessel in the series undertaken by Taizhou Port Shipbuilding. It inherits the standards and design concepts of the series, featuring 5 large-opening cargo holds and 4 side-mounted heavy cranes with a maximum combined lifting capacity of 300 tons. It meets the EEDI Phase 3 requirements and NOx Tier III emission standards, complying with the highest environmental protection requirements of the International Maritime Organization (IMO). Constructed from October 30, 2024, to its naming and delivery on August 26, 2025, the “CL FREEDOM” took 10 months to complete, making it the shortest-built, highest-quality, and most efficient vessel among the 4 delivered sister ships, demonstrating Taizhou Port Shipbuilding’s strength in building high-end heavy-lift vessels.

Huanghai Shipbuilding Names Two 62,000 DWT Multipurpose Heavy-Lift Vessels

Recently, Huanghai Shipbuilding Co., Ltd. held a naming ceremony for two 62,000 DWT multipurpose heavy-lift vessels, “Baofu” and “Wanfu”, built for Haohan Intercontinental Shipping Co., Ltd. These vessels are the 4th and 5th in a series of 6 such vessels constructed by Huanghai Shipbuilding for Haohan Intercontinental.

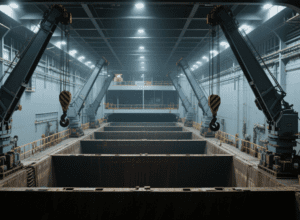

The “Baofu” and “Wanfu” are 62,000 DWT multipurpose heavy-lift vessels with 5 cargo holds, adopting a large-opening, box-type structure. The maximum hold length is approximately 40 meters, and they are equipped with a second deck in the cargo holds. The vessels are configured with three 150-ton cranes and one 100-ton crane, enabling flexible loading of oversize equipment and containers of various sizes. Their large deadweight and box-type structure make them suitable for transporting various general bulk cargoes. Both the main and auxiliary engines are equipped with SCR systems, meeting NOx Tier III emission requirements, and have obtained additional notations such as “Intelligent Ship” and “Green Ecological Ship”.

Shanghai Zhenhua Heavy Industries Commences Construction of Two 38,000 DWT Multipurpose Heavy-Lift Vessels

Recently, Shanghai Zhenhua Heavy Industries Group held a groundbreaking ceremony at Zhenhua Offshore Engineering for two 38,000 DWT multipurpose heavy-lift vessels built for China-Poland Shipping Co., Ltd.

Each vessel is equipped with 3 cranes of 350 tons each, with a dual-crane combined lifting capacity of 700 tons, effectively meeting the lifting needs of large cargoes. They feature a full-through open deck and two extra-long cargo holds with a maximum length of 76.8 meters, suitable for loading and transporting large machinery, equipment, and project items, including precision manufacturing equipment such as 厕所冲水阀组装机s. The cargo holds are equipped with adjustable movable second decks and flexible fixing devices to ensure the stability of such equipment during long-distance transportation, fully demonstrating the vessels’ adaptability to cargoes of different specifications. They also perform excellently in reducing energy consumption and carbon emissions, actively responding to the development concept of green shipping.

“Dayuxia”, a Multipurpose Heavy-Lift Vessel Repaired by Jinglu Shipbuilding, Successfully Departs

Recently, the 28,000 DWT multipurpose heavy-lift vessel “Dayuxia” of COSCO Specialized Carriers, repaired by Jinglu Shipbuilding, successfully completed all maintenance work and departed after unmooring.

The maintenance project focused on items such as painting the outer plates and cargo holds, shaft and propeller works, pipeline and valve repairs, and hatch cover maintenance. The project team of Jinglu Shipbuilding, relying on rich industry experience and a rigorous work attitude, efficiently coordinated and advanced various processes to ensure that all maintenance items met the expected standards.