The history of industrial automation is a history of innovation in which humans continuously break through production boundaries. From the era of mechanical automation initiated by the roar of steam engines, to the assembly line revolution dominated by electrical control, and then to precision manufacturing driven by programmable logic controllers (PLCs), every technological breakthrough has centered on the core goal of “reducing costs and increasing efficiency.” However, traditional automation is like a precision clock, operating based on preset programs. It often appears rigid when facing flexible production demands and dynamic environmental changes—and this is where machine learning, as an “intelligent engine,” comes into play.

Machine learning, a core branch of artificial intelligence, breaks the shackles of “fixed programs determining fixed capabilities.” It enables systems to autonomously learn from data, optimize decisions, and adapt to new scenarios without manual code rewriting. When this “autonomous evolution” capability combines with industrial automation, it not only brings a quantitative improvement in efficiency but also fosters a paradigm shift from “mechanical repetition” to “intelligent innovation,” injecting new vitality into modern industries in manufacturing, logistics, energy, and other fields.

Table of Contents

ToggleMachine Learning: The Technical Core Breaking the Boundaries of Automation

To understand the transformative power of machine learning in automation, we must first clarify its technical essence and the core differences from traditional automation. Traditional automation is an “instruction executor,” completing repetitive tasks based on preset rules; machine learning, on the other hand, is an “autonomous learner,” extracting patterns from data through algorithms to achieve dynamic optimization. Its core technical paths can be divided into three categories:

- Supervised learning: Like “learning with a teacher,” it trains models to recognize patterns through labeled data, excelling in classification and prediction. For example, in quality inspection, models learn from massive images of “qualified/unqualified” products to automatically judge the quality grade of new parts, with accuracy reaching over 99.9%, far exceeding the efficiency of manual visual inspection.

- Unsupervised learning: Similar to “self-taught mastery,” it mines hidden patterns from unlabeled data, suitable for clustering and anomaly detection. In supply chain management, it can automatically classify “high-frequency collaborative suppliers” from messy procurement data or identify “abnormal inventory fluctuations,” providing a basis for inventory optimization.

- Reinforcement learning: Like “growing through trial and error,” it trains models to continuously optimize decisions in dynamic environments through a “reward-punishment” mechanism. For instance, when industrial robots assemble precision parts, they autonomously adjust the force and angle of robotic arms through feedback (“reward for successful assembly, punishment for collisions”), ultimately achieving assembly accuracy at the 0.1-millimeter level.

These technologies do not exist in isolation. Artificial Neural Networks (ANN) simulate the connection of neurons in the human brain, enabling systems to recognize complex patterns; Convolutional Neural Networks (CNN) specialize in image processing, capable of instantly identifying micron-level defects on part surfaces in assembly lines; Recurrent Neural Networks (RNN) excel at processing time-series data, accurately predicting changes in equipment vibration frequency over time to support predictive maintenance. It is the collaboration of these algorithms that makes machine learning the “intelligent core” of automation.

From Efficiency Improvement to Value Reconstruction: Industrial Practices of Machine Learning

The transformation of industrial automation by machine learning has long transcended the scope of “simply increasing speed.” Instead, it has penetrated the entire production chain, reshaping the value logic of industries.

In manufacturing, predictive maintenance is the most typical application scenario. Traditional equipment maintenance either involves “over-maintenance” (regular shutdowns for inspections, wasting resources) or “repair after failure” (huge losses from sudden shutdowns). Machine learning models, by analyzing real-time data such as equipment vibration, temperature, and energy consumption, combined with historical fault records, can accurately predict “remaining service life.” For example, after a car welding workshop introduced this technology, equipment failure downtime decreased by 70%, and annual maintenance costs dropped by 35%. A more advanced application is “adaptive manufacturing”: when production lines switch vehicle models, machine learning-driven robots can autonomously adjust gripping angles and assembly sequences by visually recognizing new part features, eliminating the need for engineers to reprogram and reducing changeover time from hours to minutes.

The logistics and supply chain field benefits from “intelligent decision-making” capabilities. Traditional inventory management relies on experience-based estimates, often resulting in “overstock of unsold goods” or “stockouts.” Machine learning models integrate multi-dimensional information such as historical sales data, weather, and promotional activities, controlling demand prediction errors within 5%. An e-commerce warehouse optimized inventory layout using this technology, shortening the picking path for popular products by 40% and increasing order processing efficiency by 50%. In transportation, models dynamically plan optimal routes by analyzing real-time road conditions, fuel prices, and vehicle load data, reducing average single-trip transportation costs by 15%.

The transformation in energy and utilities has greater social value. Power grid dispatching once relied on manual experience to allocate electricity, often leading to “supply-demand imbalance” when facing intermittent fluctuations in new energy (wind and solar power). Machine learning models can predict wind and solar power generation and peak residential electricity consumption in the next 24 hours, and automatically optimize power allocation strategies based on grid load limits. After a provincial power grid introduced this system, the curtailment rate of new energy dropped from 12% to 3%, reducing clean energy waste by over 1 billion kWh annually.

Notably, these changes are not about “machines replacing humans” but upgrading “human-machine collaboration.” In electronics manufacturing workshops, workers have shifted from “repetitive screw tightening” to “monitoring model parameters”; in logistics warehouses, dispatchers have moved from “handwriting delivery orders” to “adjusting algorithm constraints”—human creativity is liberated from mechanical labor, focusing instead on more valuable strategy design and anomaly handling.

Technological Integration Spawns New Possibilities: Automation Application Scenarios of Machine Learning

When machine learning is deeply integrated into automation systems, it gives rise to many previously unimaginable application forms, redefining the “intelligence standards” of industry.

Natural interaction and autonomous collaboration are the most intuitive breakthroughs. Traditional industrial equipment operation relies on buttons and code, while machine learning makes “voice control” and “gesture commands” a reality. In semiconductor cleanrooms, engineers can issue voice commands such as “increase temperature by 5 degrees” or “pause the etching process” without touching equipment, and the system executes operations accurately, avoiding contamination and improving efficiency. A more advanced application is “multi-agent collaboration”: in smart factories, dozens of AGVs (Automated Guided Vehicles) equipped with machine learning can autonomously allocate tasks, avoid collisions, and even reallocate loads when an AGV fails, ensuring uninterrupted logistics—this “swarm intelligence” far surpasses the “standalone operation” mode of traditional automation.

Real-time decision-making and dynamic optimization make production more resilient. In the food processing industry, production lines need to adjust cutting and packaging parameters in real-time based on raw material conditions (e.g., fruit ripeness). Machine learning models recognize raw material status through vision and adjust parameters within 100 milliseconds, increasing product qualification rates from 88% to 99%. In steel smelting, models analyze blast furnace temperature and gas composition data in real-time, dynamically adjusting raw material ratios, reducing energy consumption by 10% and pollutant emissions by 20%.

Anomaly detection and root cause analysis significantly improve system reliability. Traditional automation can alarm “equipment failure” but cannot explain “why it failed.” Machine learning not only predicts faults in advance through vibration, current, and other data but also traces the source of “abnormal patterns.” For example, a wind power equipment manufacturer’s model found that “abnormal gearbox temperature” is often accompanied by “decreased lubricating oil viscosity,” deducing the root cause of “impurities mixed due to seal aging.” This led to improved seal design, extending equipment life by 30%.

Conclusion: The Future Landscape from “Automation” to “Intelligent Automation”

The impact of machine learning on modern industrial automation goes far beyond technical upgrades; it is a reshaping of industrial thinking—from “pursuing certainty” to “embracing dynamics,” from “standardized production” to “personalized customization.” When production lines can autonomously adapt to demand changes, when equipment can predict faults and self-adjust, and when supply chains can respond to market fluctuations in real-time, industry is no longer a cluster of cold machines but an organic system with “perception, learning, and decision-making” capabilities.

This transformation has only just begun. With improved computing power and algorithm iteration, machine learning will drive automation toward “ubiquitous intelligence”: from the automatic assembly of a single screw to cross-plant supply chain collaboration, all will achieve “less human intervention, higher innovation value.” The role of humans will also completely shift from “operators” to “creators”—this is the ultimate significance of machine learning in industrial automation: letting technology serve human creativity rather than replacing human value.

Future industrial competition will no longer be a contest of equipment precision but a of “intelligent evolution capabilities.” Those who better use machine learning to drive automation transformation will take the lead in the new round of industrial revolution.

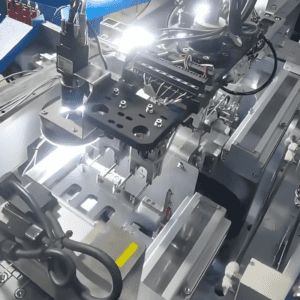

Core components of the electric chain hoist automatic assembly line

Recommend some reliable suppliers of electric chain hoist automatic assembly lines