CNC Precision Machining Technology for Five-Axis Medical Parts

In modern medical device manufacturing, the five-axis precision CNC machining technology for medical parts is a crucial and indispensable link. This technology makes use of advanced five-axis simultaneous motion CNC machine tools, which are capable of extremely precise processing of metals or other biocompatible materials.

Biocompatible materials are those that, when in contact with biological systems such as human tissues, do not trigger harmful reactions or excessive stimulation. They need to maintain their physical and chemical properties and avoid causing any form of damage or adverse effects on biological tissues. Examples of such materials often used in medical part manufacturing include stainless steel, titanium alloys, and some special plastics. These materials not only have the necessary mechanical strength and durability to adapt to the complex physiological environment but also meet the strict requirements of biocompatibility to ensure the safety of patients when the medical parts are implanted or used in the human body.

The ability of five-axis precision CNC machining technology is of vital importance for the manufacturing of highly demanding medical components such as surgical instruments, bone plates, and joint implants. These components usually have very complex shapes. For instance, surgical instruments may require intricate geometries to meet the needs of different surgical operations, and joint implants need to be precisely shaped to fit the patient’s body structure accurately. Moreover, the dimensional accuracy and surface finish of these components are directly related to the treatment effect and safety of patients. High – dimensional accuracy ensures that the parts fit together correctly, and excellent surface finish can reduce the risk of infection and improve the comfort of patients during the treatment process. Notably, in the integrated manufacturing of medical equipment prototypes that combine mechanical structures and electronic control modules, this high-precision machining technology also synergizes with 电子元件自动加载组装机—the CNC-machined precision housings and mounting slots provide standardized positioning benchmarks for the automatic assembly equipment, enabling it to accurately load and assemble microelectronic components like sensors and connectors onto medical devices, ensuring the integration accuracy of mechanical and electronic systems.

Five-Axis CNC Medical Machining

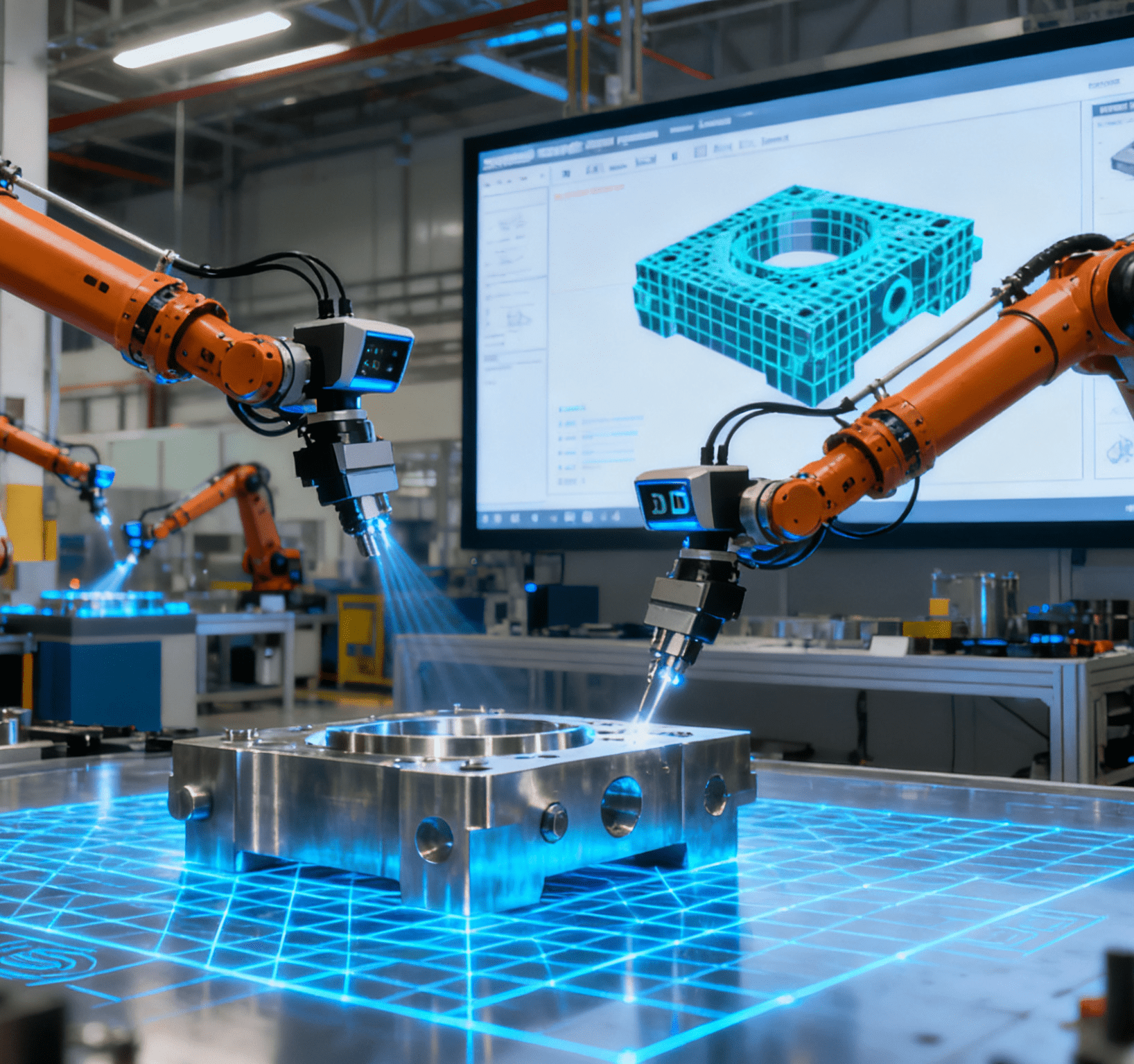

Five-axis CNC machining is a highly advanced manufacturing technology. It enables the processing equipment to move or rotate simultaneously in five different directions. For the manufacturing of medical parts, this is especially useful. Many medical components, such as surgical tools or implants used in the body, often have complex shapes with numerous curved surfaces and fine details. Ordinary machines struggle to process these shapes effectively. Five-axis CNC machining, however, can easily handle such complex geometries. It can cut and shape materials from almost any angle, precisely creating the exact form required by the design drawings. Therefore, this five-axis CNC machining technology serves as a fundamental cornerstone for the production of high-quality and complex-shaped medical parts.

Micron-Level Precision Assurance

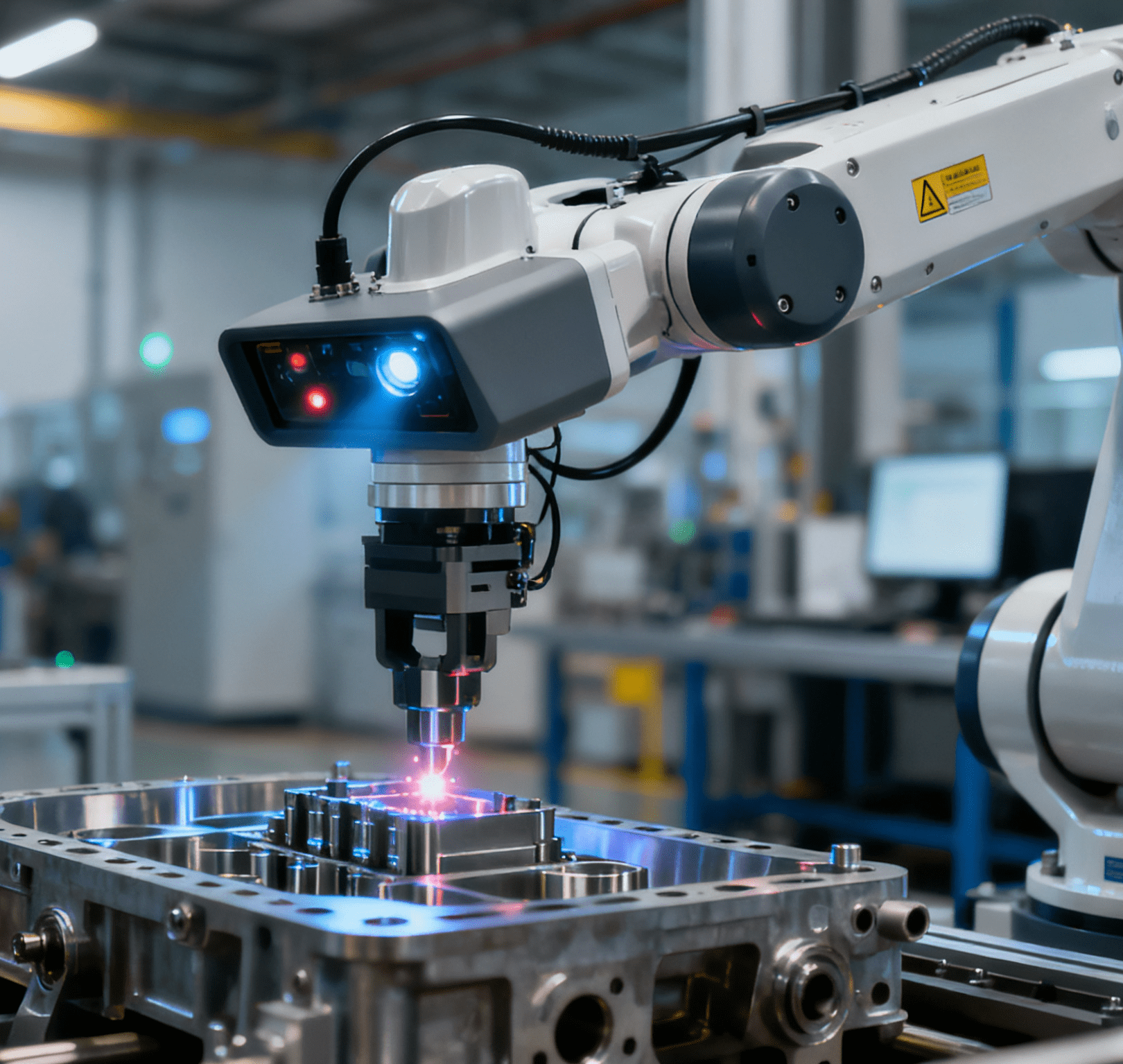

Achieving micron-level precision during the processing of medical parts is the core to ensuring product reliability. Through advanced five-axis CNC machining technology, the equipment can precisely control the tool path and processing parameters to minimize errors. The CNC precision CNC system is equipped with high-sensitivity sensors that monitor the processing status in real-time and make timely adjustments to ensure that the tolerance remains within the micron range.

For example, when manufacturing implants, this technology can stably handle complex geometries and avoid even the slightest deviation. Take a hip joint implant as an example. Its surface needs to be precisely processed to match the patient’s bone structure perfectly. The five-axis CNC machining technology can ensure that the surface roughness and dimensional accuracy of the implant reach the required standards, reducing the risk of loosening or inflammation after implantation.

Combined with the ISO-certified quality system, every step, from raw material inspection to final product inspection, is strictly controlled. This ensures the safety and consistency of the parts. The high-precision capabilities provide a solid foundation for the subsequent manufacturing of surgical instruments and the collaborative operation with Automated Loading Assembly Machine for Electronic Components, as the micron-level positioning accuracy of mechanical parts directly determines the assembly yield of electronic components in medical devices.

Application in Surgical Instrument Manufacturing

Thanks to its micron – level precision processing capabilities, five – axis CNC machining technology plays a pivotal role in the manufacturing of surgical instruments. This advanced CNC precision CNC machining method can efficiently process tools such as scalpels, forceps, and pliers. These instruments often require complex geometries and sharp edges. For example, scalpels need to have extremely sharp cutting edges to ensure clean incisions during surgery, and the curved shapes of some forceps are designed to reach specific areas in the human body accurately.

During the processing of medical parts, the five – axis system ensures that the dimensions and surface finish of each component meet high standards. This guarantees the reliability and safety of surgical instruments. Meeting high – standard dimensions ensures that the surgical instruments fit well in the hands of medical staff and can be used accurately during operations. Excellent surface finish can prevent bacteria from adhering to the surface of the instruments, reducing the risk of infection during surgery.

This not only meets the strict requirements of the medical industry but also helps doctors reduce risks during operations. When doctors perform complex surgical procedures, they can rely on the high – quality surgical instruments produced by five – axis CNC machining technology to complete. For more complex medical equipment integrating electronic control functions, such as minimally invasive surgical robots, the precision mechanical components processed by five-axis CNC technology and the electronic components accurately assembled by Automated Loading Assembly Machine for Electronic Components together form a high-reliability system, providing strong support for the precision and stability of medical operations.

Automatic, efficient and powerful assembly machine

Technical advantages of continuous motion multi-piece assembling machine