In the five major industries of sanitary ware, auto parts, medical equipment, packaging machinery, and flexible automation, enterprises are facing common development bottlenecks: rising labor costs year by year, difficulty in stabilizing production precision, low efficiency caused by multiple batches and varieties of orders, and inability of traditional production lines to respond quickly to market changes… Automation is the core key to solving these pain points. Choosing the right automation equipment manufacturer can not only solve current problems but also lay a solid foundation for long-term competitiveness. Ruizhi Intelligent Manufacturing is precisely an automation solution partner focusing on these five industries.

I. First, Understand: What is Automation? What is Automation Equipment?

Many enterprises know they “need to adopt automation” but have a limited understanding of core concepts, leading to detours in subsequent equipment selection. In fact, it is easy to

understand:

Automation

Simply put, it means “enabling machines to work independently according to preset logic”. Through technical means, it replaces manual labor in repetitive, precise, and high-intensity production links, while realizing real-time monitoring, analysis, and optimization of production data. Ultimately, it achieves the goals of “cost reduction, efficiency improvement, quality stabilization, and consumption reduction”. For example, in the polishing of sanitary ware products, manual work not only generates a lot of dust and has poor precision but also is prone to fatigue and errors; automation equipment can operate at a constant speed 24 hours a day, with errors controlled within 0.1mm.

Automation Equipment

It is a combination of “hardware carrier + software system” to realize automation. It is not a single machine but a “customized solution” adapted to specific industry scenarios. For example:

Intelligent polishing production lines for the sanitary ware industry (including robotic arms, visual positioning, and dust collection systems);

Precision assembly robot workstations for the auto parts industry (with force control detection to ensure accurate bolt tightening torque);

Aseptic automated assembly lines for the medical equipment industry (complying with GMP standards to avoid manual contamination);

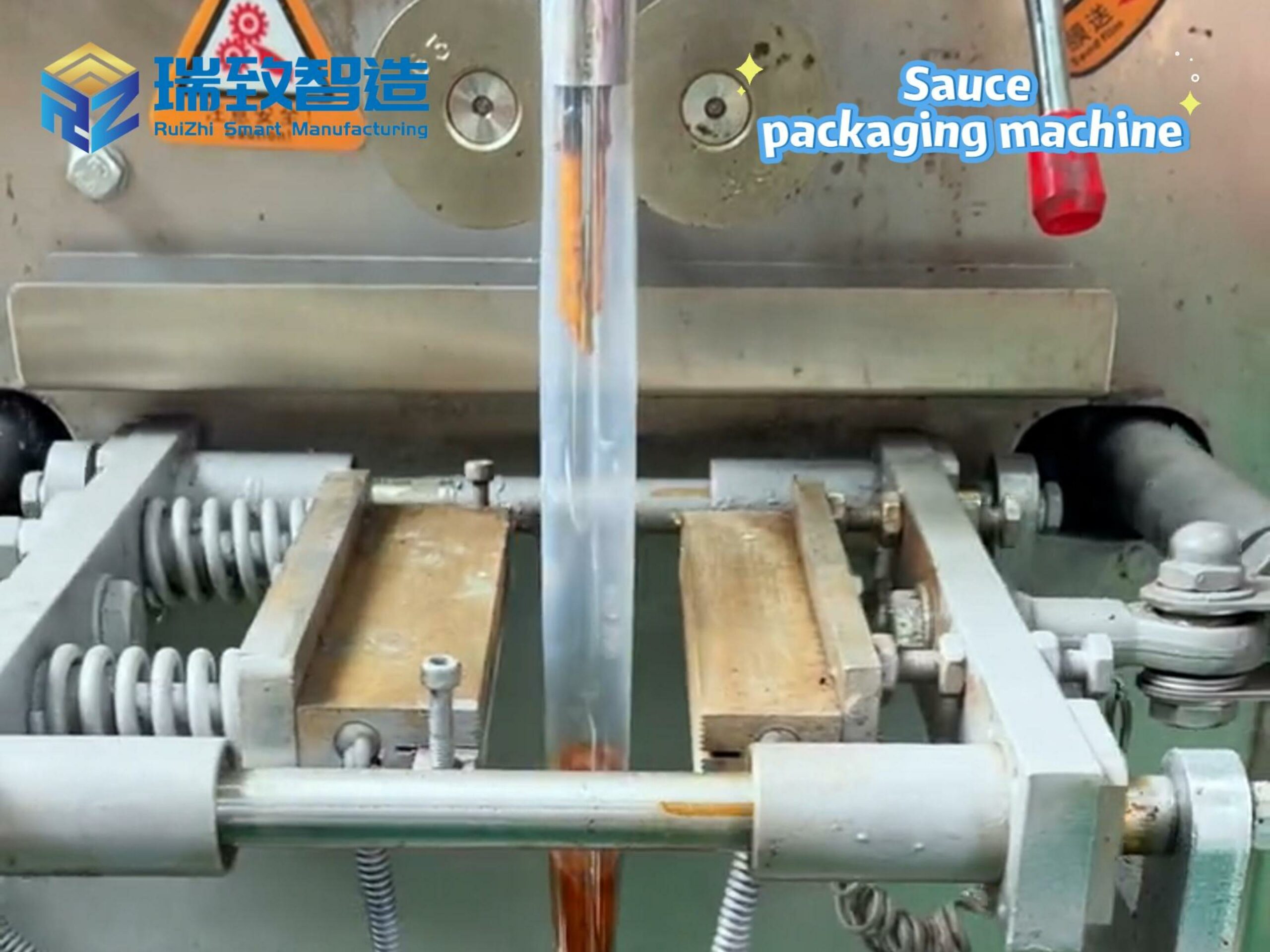

Flexible packaging machines for the packaging industry (enabling quick switching of packaging processes for products of different specifications);

Modular production lines in the field of flexible automation (adaptable to multi-variety and small-batch production through software adjustments).

II. “Automation Needs” of the Five Major Industries: If You Don’t Upgrade, You Will Really Fall Behind!

Each industry has different production characteristics, and its demand for automation equipment also varies. Blindly following the trend to “adopt equipment” will only waste costs. Let’s first analyze the core pain points and automation solutions of each industry:

1. Sanitary Ware Industry: From “Manual Dependence” to “Precision Mass Production”

Pain Points: Polishing of products (such as toilets and bathroom cabinets) relies on manual labor, resulting in severe dust pollution and high employee turnover; size errors between different batches of products are large, affecting installation adaptability.

Automation Needs: Visual-guided polishing equipment that can adapt to curved and irregular parts, as well as intelligent quality inspection systems (identifying surface defects through AI vision), to realize the fully unmanned process of “polishing – quality inspection – sorting”.

2. Auto Parts Industry: “High Precision” is the Lifeline

Pain Points: The assembly precision of parts (such as bearings and sensors) is extremely high (tolerance often reaches 0.001mm), and manual assembly is prone to errors; production lines need to meet the “flexible production” requirements of automobile OEMs and frequently switch parts supporting different vehicle models.

Automation Needs: Robotic precision assembly lines (with torque feedback and visual positioning) and flexible conveying systems (enabling quick model change) to ensure both precision and production capacity meet standards.

3. Medical Equipment Industry: “Asepsis + Compliance” are Indispensable

Pain Points: The production of medical consumables (such as syringes and infusion sets) and small medical equipment (such as blood glucose meters) requires an aseptic environment, and manual operation is prone to introducing pollution; production data needs to be traceable throughout the process to meet the compliance requirements of drug regulatory authorities.

Automation Needs: Aseptic automated assembly lines (with closed design and complying with GMP standards) and full-process data traceability systems (connecting to MES to record production parameters at each step).

4. Packaging Machinery Industry: “Flexible Response” to Multi-Specification Orders

Pain Points: Consumer goods packaging (such as food and daily chemicals) often faces “small-batch, multi-variety” orders. Traditional packaging machines take 2-4 hours to change models, seriously affecting efficiency; packaging precision (such as seal tightness and label position) directly affects product qualification rate.

Automation Needs: Flexible packaging machines (model change time shortened to within 30 minutes) and online packaging inspection systems (real-time monitoring of seal quality and label precision).

5. Flexible Automation Industry: “Quick Response” is the Core Competitiveness

Pain Points: “Multi-variety, small-batch” production has become the mainstream in the current manufacturing industry. Traditional fixed production lines cannot adapt, resulting in high equipment idleness rate; adjusting production lines requires a lot of manual modification, which is time-consuming and labor-intensive.

Automation Needs: Modular flexible production lines (production processes can be adjusted through software programming) and production line digital twin systems (simulating adjustment effects in advance to reduce downtime).

III. Key Step: How to Choose the Right Automation Equipment Manufacturer? 4 Core Standards to Avoid Mistakes!

Many enterprises spend a lot of money on automation but find that the equipment is “incompatible”—either it cannot adapt to the existing production lines, there is no after-sales support, or it cannot keep up with new order requirements after half a year of use. In fact, as long as you grasp the following 4 standards when choosing a manufacturer, you can avoid 90% of detours:

Standard 1: Focus on “Industry Customization Capability” Rather Than “General Equipment Sales”

A good manufacturer does not “sell machines” but “provide solutions”. For example, Ruizhi Intelligent Manufacturing will not provide a set of general polishing equipment to all sanitary ware enterprises. Instead, it first conducts on-site surveys of the enterprise’s product size, production rhythm, and existing workshop layout, then customizes an overall solution of “equipment + software + layout”—this is practical automation.

Standard 2: Focus on “Industry Case Accumulation” Rather Than “Verbal Commitments”

Has the manufacturer served leading enterprises in the same industry? How is the equipment operation effect? For example, when choosing an automation manufacturer for auto parts, you should check whether it has cases of supporting OEM supply chain enterprises and whether the precision meets standards; when choosing a manufacturer for medical equipment, you should check whether it has project experience complying with GMP standards. Ruizhi Intelligent Manufacturing has mature cases in all five industries and can provide customers with on-site inspection channels to witness the equipment operation effect in person.

Standard 3: Focus on “Full-Cycle After-Sales Service” Rather Than “One-Time Sales”

Automation equipment is not a “one-time purchase and no more worries” product. Subsequent commissioning, maintenance, and upgrading are crucial. For example, can the manufacturer respond within 24 hours if the equipment breaks down suddenly? Does it provide operator training? Can the equipment be upgraded and modified when subsequent orders change? Ruizhi Intelligent Manufacturing provides “1-year free warranty + lifelong maintenance + regular inspection” and also conducts on-site employee training to ensure the long-term stable operation of the equipment.

Standard 4: Focus on “Cost-Effectiveness” Rather Than “Low Price”

Low-priced equipment often hides hidden risks: for example, using inferior accessories leads to frequent failures, or lacking data connection functions, making it impossible to integrate into the enterprise’s subsequent digital upgrading. True cost-effectiveness lies in “equipment stability + long-term benefits”—although the equipment of Ruizhi Intelligent Manufacturing is not the cheapest, its core components adopt imported brands, with a failure rate as low as less than 0.5%, and it supports connection with MES and ERP systems, leaving sufficient space for the enterprise’s subsequent digital transformation.

IV. Ruizhi Intelligent Manufacturing: The “Exclusive Automation Partner” for the Five Major Industries

Why do more and more enterprises in the sanitary ware, auto parts, medical equipment, packaging machinery, and flexible automation industries choose Ruizhi Intelligent Manufacturing?

Because we focus on “in-depth industry cultivation” rather than “extensive expansion”:

Technically

We have an R&D team of more than 100 people, with core members from the fields of automation, mechanical design, and AI vision. We can customize solutions for the pain points of each industry—for example, the “curved surface adaptive polishing algorithm” developed for sanitary ware enterprises and the “torque closed-loop control assembly system” designed for auto parts enterprises have all been verified by the market.

In Terms of Cases

We have served TOP 10 enterprises in the sanitary ware industry, leading suppliers in the auto parts industry, and compliant medical equipment enterprises. The stable operation rate of the equipment exceeds 99%, helping customers reduce labor costs by an average of 30%, increase production efficiency by 40%, and raise product qualification rate from 95% to 99.8%.

In Terms of Service

We have established a full-process service system covering “pre-sales research – scheme design – equipment production – installation and commissioning – employee training – after-sales maintenance”, with 24-hour online response, ensuring that enterprises “have no worries about adopting automation and feel more at ease when using automation”.

V. Want to Upgrade Automation? Start with “Free Scheme Consultation”!

If your enterprise is facing problems such as high labor costs, low efficiency, and poor precision, and wants to know how automation can adapt to your production scenario, please feel free to contact Ruizhi Intelligent Manufacturing—we provide free on-site research + industry-specific scheme design, help you calculate the “automation input-output account”, and avoid blind investment.

Ruizhi Intelligent Manufacturing does not produce “general equipment” but only provides “automation solutions suitable for you”, accompanying you to “reduce costs, increase efficiency, and win in the future” in industry competition!

Phone/WhatsApp: 15860091967

电子邮件:644349350@qq.com