Table of Contents

ToggleAutomatic Iron Rod Loading/Unloading System: Redefining Heavy-Duty Material Handling Efficiency

In industries where iron rods serve as the backbone of production—from steel manufacturing to machinery 加工 and construction—manual loading/unloading is a relic of the past. Handling long, heavy iron rods (ranging from 6mm to 200mm in diameter and up to 12 meters in length) is labor-intensive, dangerous, and prone to inconsistencies. Misalignments during loading can damage CNC machines, while manual lifting leads to high rates of workplace injuries. Enter the 自动化铁杆装卸系统—a robust, intelligent solution engineered to streamline material flow, enhance safety, and boost productivity in high-volume, heavy-duty environments.

The Imperative for Automation in Iron Rod Handling

Iron rods are far from uniform: their weight (5kg to 500kg per meter), surface textures (smooth, rusted, or coated), and storage configurations (stacked, 捆扎,or on conveyors) create unique challenges:

1. Safety Risks

Manual handling of 6-meter-long rods requires 2–4 workers, exposing them to risks of back strain, cuts, and dropped loads—accounting for 30% of industrial accidents in metalworking plants.

2. Efficiency Bottlenecks

Loading a CNC lathe with a 10-meter iron rod manually takes 5–10 minutes per part, slowing down production lines and limiting machine utilization.

3. Precision Deficits

Human operators struggle to align rods within ±2mm of positional accuracy, leading to vibrations during machining and subpar surface finishes.

Core Technologies: The Brain and Brawn of Heavy-Duty Automation

1. Robust Mechanical Design for Extreme Loads

The system’s hardware is built to withstand the rigors of iron rod handling:

- Dual-Sided Gantry Cranes: Support loads up to 5 tons, equipped with anti-vibration dampeners to stabilize rods during transport.

- Magnetic/Mechanical Grippers:

- Electromagnetic Grippers: Securely hold uncoated iron rods using adjustable magnetic force (500N to 50kN), ideal for smooth surfaces.

- Hydraulic Clamps: Grip rusted or textured rods with serrated jaws, applying up to 10kN of clamping force without slippage.

- Servo-Driven Carriages: Achieve positioning accuracy of ±1mmalong X-Y-Z axes, critical for aligning rods with machine chucks or storage racks.

2. Intelligent Vision and Sensor Fusion

A combination of technologies ensures error-free handling:

- 3D Laser Scanning: Maps the position and orientation of stacked rods in real time, even in poorly lit warehouses, with 99.9% accuracy.

- Load Cells and Torque Sensors: Monitor gripper force to prevent overloading (e.g., alerting operators if a rod is bent and weighs 15% more than standard).

- RFID Integration: Reads rod specifications (diameter, length, heat treatment status) directly from tags, auto-adjusting system parameters for each part.

3. Advanced Control Software

The system’s software ecosystem enables seamless operation:

- PLC-Based Logic: Controls multi-axis movement, integrating with machine tools (CNC lathes, milling machines) via standardized protocols (EtherCAT, Modbus).

- AI-Powered Path Optimization: Algorithms calculate the shortest, safest route for each rod, reducing travel time by 20–30% compared to rule-based systems.

- HMI Interface: Provides real-time diagnostics, error logs, and production metrics (e.g., parts handled per hour, downtime reasons) for easy monitoring.

Transforming Industries: Applications Across the Value Chain

1. Steel Manufacturing: From Billets to Finished Rods

In a steel mill producing 10,000 tons of iron rods daily:

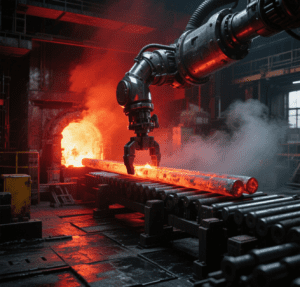

- Loading Hot Rolling Mills: The system picks red-hot billets (1,100°C) from conveyor belts using heat-resistant grippers, reducing operator exposure to high temperatures.

- Unloading Straightening Machines: Places straightened rods into storage racks with 100% alignment, enabling automated inventory management.

Result: Production throughput increases by 40%, while heat-related injuries drop by 85%.

2. Machinery Machining: Precision CNC Loading/Unloading

In a lathe workshop machining 50mm-diameter shafts:

- The system aligns rods with the machine’s chuck within ±0.5mm, eliminating manual centering (a 2-minute task per part).

- After machining, it unloads finished parts and loads new rods in a seamless cycle, boosting machine utilization from 60% to 95%.

Case Study: A tier-2 automotive supplier cuts setup time by 75%, producing 200 more parts per day with zero misloading errors.

3. Warehouse & Logistics: Efficient Palletizing and Storage

For a metal distribution center managing 10,000+ rod SKUs:

- Mixed-Length Stacking: Handles rods from 2m to 12m in the same system, using vision to optimize pallet layouts and prevent overhang.

- Automated Inventory Tracking: Updates WMS in real time as rods are moved, reducing manual inventory checks by 90%.

System vs. Traditional Methods: A Performance Breakdown

| Metric | Automatic System | Manual Handling | Semi-Automatic Cranes |

| Load Capacity | 0.5–5 tons | 0.1–0.5 tons (per worker) | 1–3 tons (fixed grippers) |

| Positioning Accuracy | ±1mm | ±10mm (variable) | ±5mm (operator-dependent) |

| Cycle Time (6m rod) | 30–45 seconds | 5–10 minutes | 2–3 minutes |

| Safety Incidents | <1 per 10,000 operations | 5–10 per 10,000 | 2–3 per 10,000 |

| Cost (USD, 10m system) | $300k–$800k | N/A (labor-intensive) | $150k–$400k (limited features) |

The Business Case: From Elastic Challenges to Tangible Gains

1. Rapid ROI Driven by Quality and Speed

- Labor Savings: Replaces 2–4 operators per line, saving $60k–$100k annually in labor costs (especially in high-wage regions).

- Yield Improvements: Reduces spring deformation and misplacement errors by 90%, critical for applications where 0.1mm misalignment causes product failure.

- Scalability: Handles 24/7 production with 98% uptime, supported by predictive maintenance (e.g., alerts for gripper wear or joint backlash).

2. Future-Ready Flexibility

- Multi-SKU Adaptability: Stores 100+ spring profiles in its database, enabling quick 切换 between compression, torsion, and extension springs with zero manual programming.

- IoT Integration: Feeds real-time data (grip force, cycle times, defect locations) to factory analytics platforms, enabling predictive quality control.

The Evolution of Spring Handling: Where Dexterity Meets Intelligence

As industries demand smaller, more complex springs (e.g., micro-coils for MEMS devices or variable-rate springs for electric vehicles), the 6-axis system evolves with:

- Self-Calibrating Tools: On-tool sensors auto-detect spring dimensions, eliminating setup time for new part numbers.

- AI-Powered Defect Prediction: Uses historical data to anticipate spring deformation risks based on material type and handling speed.

- Collaborative Safety: Equipped with 3D safety scanners, works alongside human technicians in shared workcells—ideal for R&D prototyping or low-volume custom spring production.

In a world where the performance of entire systems hinges on the precision of tiny springs, the 6-Axis Robotic Spring Pick-and-Place System is not just an upgrade—it’s a necessity. It turns the inherent challenges of elastic component handling into a competitive advantage, empowering manufacturers to achieve new levels of quality, speed, and flexibility.

#6Axis Spring Handling #Robotic Spring Assembly #Precision Pickand Place System