- The Race to Electrify: Why Flexibility Defines EV Manufacturing Success

The global shift to electric vehicles (EVs) is no longer a trend—it’s a race. Automakers, both legacy giants and agile startups, are scrambling to scale production: converting ICE factories, building new lines, and ramping up output to meet surging consumer demand and regulatory deadlines. But EV manufacturing isn’t just a tweak to traditional auto production; it’s a fundamental reimagining. Batteries, e-axles, and electric motors replace engines and transmissions, introducing new materials, complex assemblies, and tighter tolerances.

In this high-stakes environment, “fast” isn’t enough. What automakers need is agility—the ability to adapt to evolving designs, scale up quickly, and integrate new technologies without derailing production. Enter flexible automation: a suite of adaptive, interconnected technologies that don’t just speed up assembly, but future-proof it. From intelligent welding systems to modular transport lines, these tools are the backbone of modern EV manufacturing, turning the chaos of into a competitive edge.

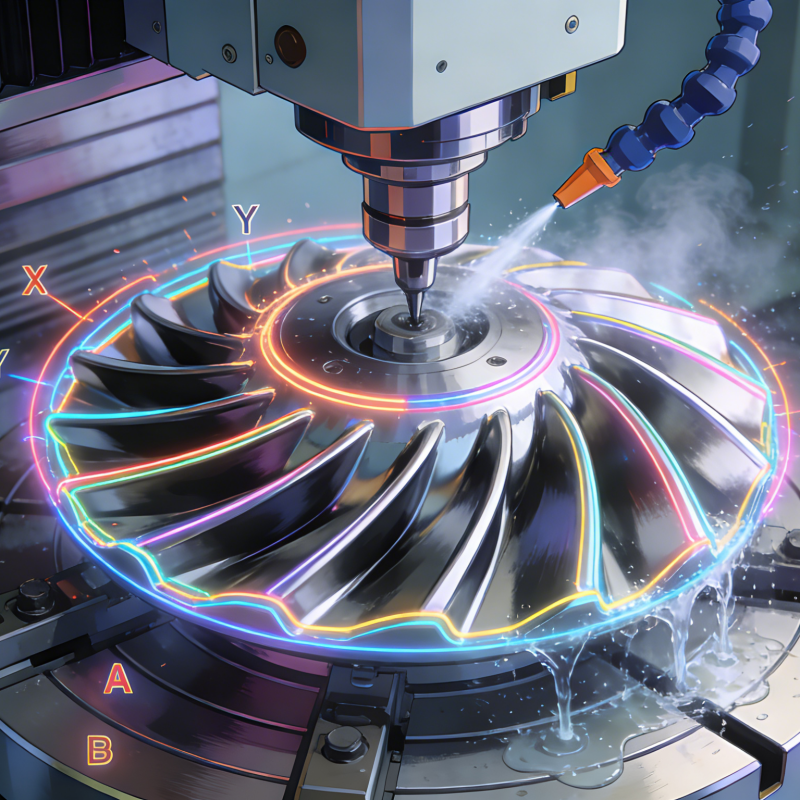

- Welding Reimagined: Tackling EVs’ Unique Material and Structural Challenges

EVs demand more from welding than their ICE predecessors. Gone are the days of standard steel frames; today’s EVs mix aluminum, high-strength steel, and advanced composites to cut weight and boost range. Even more revolutionary: structural battery designs, where the battery pack itself becomes part of the chassis, welded to front and rear castings to simplify frames and reduce parts.

To handle these complexities, next-gen welding controllers are rewriting the rules. Take the PRC7000 adaptive resistance welding controller: it stores up to 10,000 customizable programs, configured via drag-and-drop interfaces to match material properties and throughput needs. Its dual-processor architecture splits process control and data communication, ensuring real-time insights flow to plant management systems without compromising weld precision.

Complementing these controllers are advanced analytics tools. Weld spot analytics compile data into live dashboards, automatically flagging anomalies and optimizing sequences—critical for maintaining quality in high-volume lines where a single weak weld could compromise safety or performance.

- Smart Fastening: Precision and Traceability in Manual Assembly

Not all EV assembly is automated. Tasks like installing windshields, seats, or center consoles still rely on human operators—but with zero room for error. Here, Industry 4.0 fastening tools bridge the gap between manual work and automated precision.

Tools like the Nexo cordless Wi-Fi nutrunner integrate controllers directly into the device, measuring torque and angle for every fastener with pinpoint accuracy. They log every action, creating a digital trail that ensures traceability—essential for regulatory compliance and quality audits. Beyond precision, these tools boost flexibility: as different EV models move down the line, operators can switch between settings in seconds, no retooling required. The data they generate also fuels continuous improvement, helping engineers refine workflows and train teams more effectively.

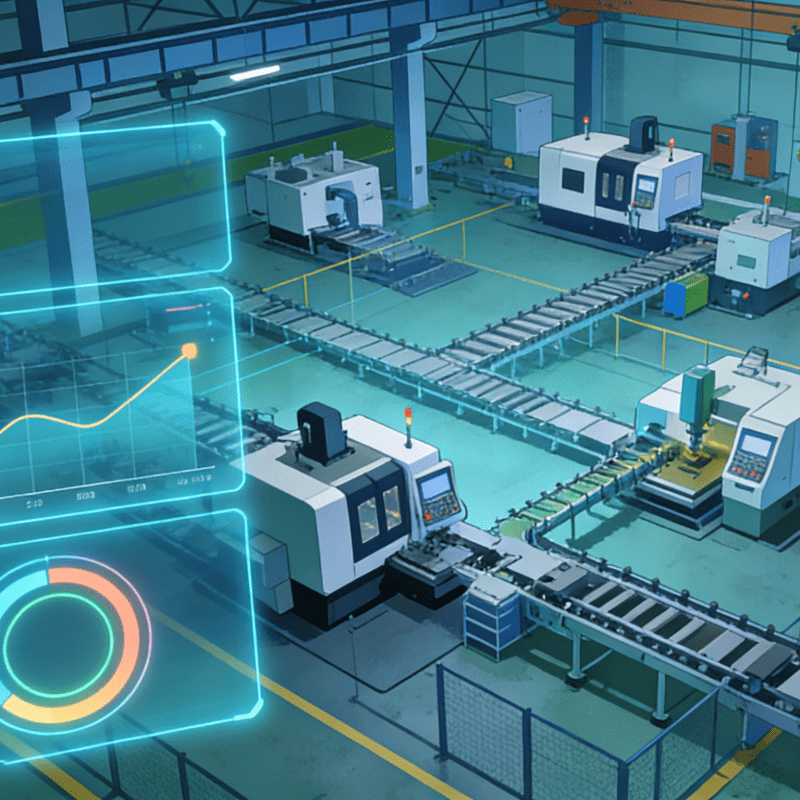

- Intralogistics: Agile Material Movement Keeps Lines Flowing

In EV factories, downtime is costly—especially when parts fail to reach workstations on time. Autonomous mobile robots (AMRs) are solving this with a level of flexibility static conveyor systems can’t match. These robots navigate via lidar, avoiding obstacles and adapting to layout changes without tracks or fixed guides. They deliver pallets, flow racks, or even entire shelves to manual stations, triggered by tablets, PLCs, or APIs connected to ERP/MES systems.

For example, an AMR can ferry battery modules to assembly cells in the morning and switch to delivering interior components in the afternoon—all without reprogramming. This adaptability cuts reliance on forklift operators and slashes material delivery times, keeping lines moving even as production schedules shift.

- Controls & Mechatronics: The Brains Behind Battery Production

Battery pack manufacturing is the heart of EV production, with four critical stages: electrode production, cell assembly, module integration, and pack testing. Each demands speed, precision, and adaptability—qualities that define modern control and mechatronic systems.

In electrode production, where layers of material are coated and pressed (calendaring), Linux-based 64-bit controllers with multicore CPUs manage tight closed-loop control, minimizing waste from breakages and ensuring consistent energy density. Platforms like ctrlX AUTOMATION take this further: modular software toolkits let engineers add features (like real-time video inspection) via apps, reducing setup time and expanding capabilities without hardware overhauls.

For cell and module assembly, “plug-and-produce” mechatronics are game-changers. Cartesian robots, delta robots, and linear handling systems come pre-configured with software, enabling quick deployment. Whether stacking pouch cells, dispensing electrolytes, or welding cell caps, these systems sync seamlessly—engineers can program motion via drag-and-drop interfaces, cutting commissioning time from weeks to days.

- Modular Transport: Moving From Cells to Packs With Adaptable Conveyors

Battery components grow in size and weight as they move from cells to full packs, requiring transport systems that evolve with them. Rigid, one-size-fits-all conveyors won’t cut it. Instead, modular systems—sourced from single suppliers for consistency—offer the flexibility to adapt.

Flexible plastic chain conveyors handle cell assemblies, navigating vertical turns and obstacles while supporting precision pallets. For faster, independent movement of larger components (like modules), linear motor-based systems (such as Bosch Rexroth’s Flexible Transport System) let individual carriers adjust speed and path, matching the pace of downstream stations.

Designing these systems early—during factory planning, not as an afterthought—prevents bottlenecks, reduces non-value-added transport time, and makes scaling up (or reconfiguring) easier as production ramps.

- End-of-Line Testing: Speed Without Sacrificing Precision

A factory churning out 50 EVs per hour needs to test a battery pack every 72 seconds. This demands testing systems that are as fast as they are accurate. Power converter platforms like the IndraDrive ML family deliver exactly that: software-controlled DC-DC drives maintain precise voltage, current, and power during cycling tests, with a compact design that saves floor space.

These systems don’t just verify performance—they log data for compliance, ensuring every pack meets safety and efficiency standards before installation.

- The Path Forward: Integrated Agility Drives EV Leadership

Scaling EV production isn’t about throwing technology at the problem—it’s about harmonizing it. Welding controllers, fastening tools, AMRs, and conveyors must work as a single system, optimized for throughput and quality. Concurrent engineering—overlapping design, programming, and integration—cuts deployment time by weeks, while partnering with suppliers with cross-technology expertise ensures seamless integration.

In the end, flexible automation is more than a production tool; it’s a strategic advantage. It lets automakers respond to new battery chemistries, adapt to design tweaks, and scale up (or down) with confidence. As the world races toward electrified mobility, the winners won’t just be those who build EVs faster—they’ll be those who build them smarter, with agility at the core of every weld, every movement, and every decision.

Brands of flexible automatic assembly equipment

What are the types of flexible automatic assembly equipment?