In the high-stakes rhythm of assembly lines, a single misstep—whether a misplaced part, a skipped step, or a wrong fastener—can ripple into costly scrap, rework delays, and damaged reputations. It’s Murphy’s Law in action: if something can go wrong, it often does. Yet these errors are far from inevitable. Today’s manufacturers are turning to intentional, data-driven strategies to outmaneuver mistakes, blending time-tested principles with smart technology to build assembly lines that thrive on precision.

The root causes of assembly errors are as varied as the lines themselves: operator fatigue, rushed workflows, misaligned parts, or miscommunication between stations. Common culprits include incorrect workpiece setup, skipped processes, missing components, or parts—each carrying steep costs. A survey by Assembly Magazine highlights the urgency: 41% of plants plan to invest in equipment this year specifically to cut scrap and rework costs, while 15% aim to reduce material waste. The message is clear: error-proofing isn’t just a nicety—it’s a strategic imperative.

Leveraging Poka-Yoke: Stopping Mistakes Before They Happen

At the heart of modern error-proofing lies poka-yoke—the Japanese principle of “mistake-proofing” that either prevents errors outright or makes them immediately obvious. Far from complex, these mechanisms are often elegant and affordable. For example, reshaping parts or fixtures so they only fit together correctly eliminates misalignment. Electronic sensors can block assembly from proceeding until the right part is in the right position. Even simple organizational tweaks—color-coded part bins, clearly displayed instructions—reduce confusion and keep workflows on track.

Poka-yoke shines in fastening, a frequent source of errors: 91% of plants still drive screws manually, per Assembly Magazine. Engineers counter this by standardizing fasteners (fewer types mean fewer mix-ups) and assigning single screw types to individual operators. Photoelectric sensors on screw presenters add another layer, tracking whether screws are present or correctly placed—turning manual work into a guided, low-error process.

Smart Tools: Intelligence as a Safety Net

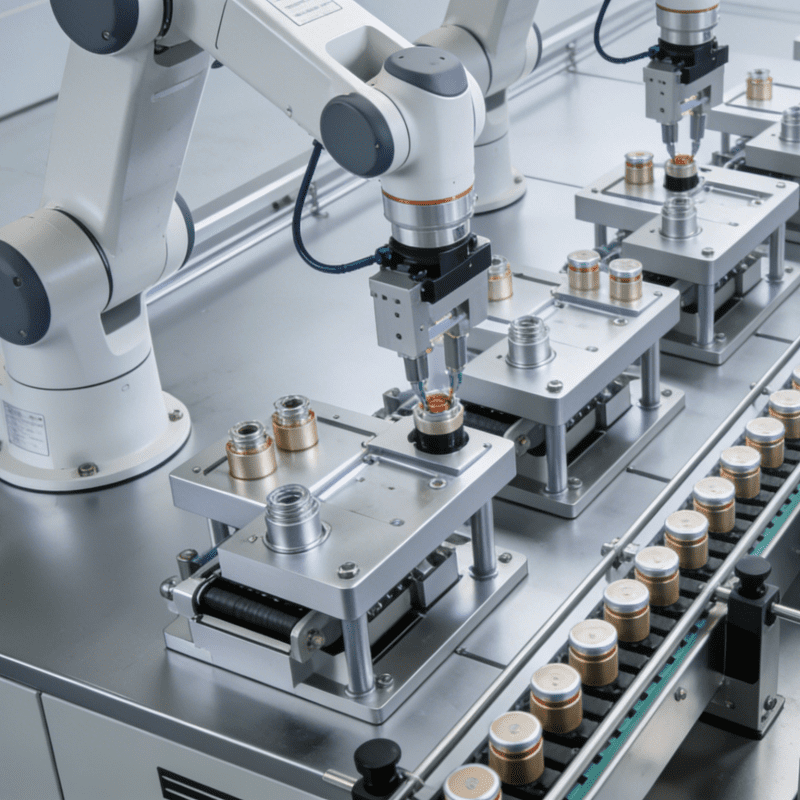

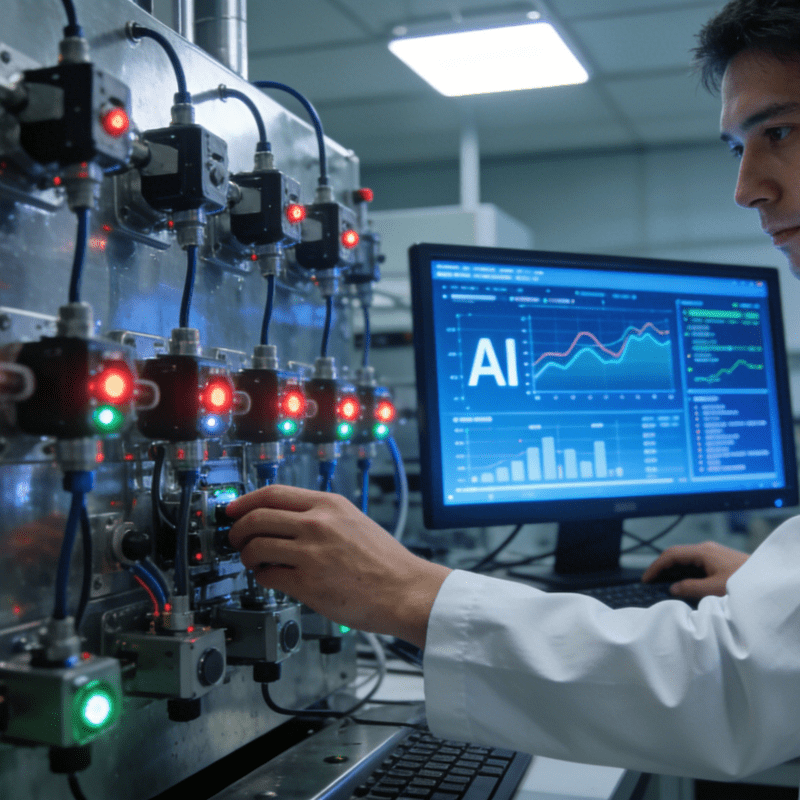

Beyond manual processes, integrated intelligence is transforming error-proofing. Tools like Deprag’s Minimat-F handheld screwdriver log cycles, detect part changes, and auto-shut off at target torque—preventing over-tightening or missed fasteners. Tool support arms provide positional feedback, while advanced systems monitor pressing, riveting, and forming operations in real time.

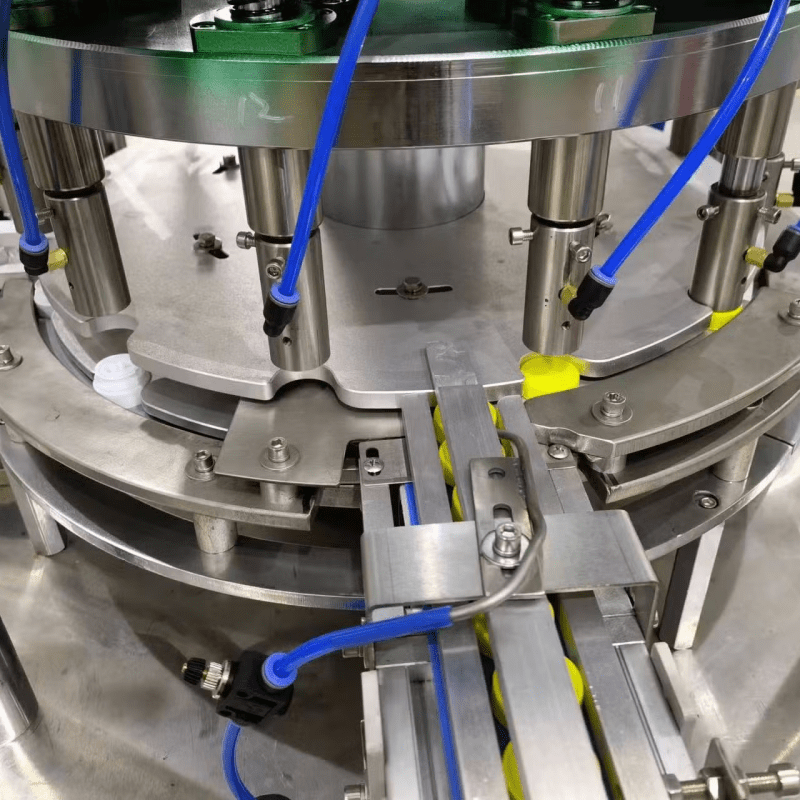

Automated lines benefit too. Poka-yoke here acts as a verification checkpoint: sensors confirm part presence, machine vision systems measure dimensions at production speed, and touch probes ensure parts seat fully. Feeder bowls even orient parts correctly before they reach the line. Together, these tools turn automation from a “set-it-and-forget-it” system into a self-correcting one.

Murphy’s Law may cast a long shadow, but assembly lines no longer have to submit to its whims. By combining poka-yoke’s proactive design with smart, data-driven tools, manufacturers are building lines that don’t just react to errors—they prevent them. The result? Lower costs, higher quality, and workflows that empower operators rather than frustrate them. In an era where precision defines competitiveness, error-proofing isn’t just a strategy—it’s the foundation of assembly excellence.