Respiratory diseases—from asthma and chronic obstructive pulmonary disease (COPD) to acute respiratory infections—affect over 1 billion people worldwide, according to the World Health Organization. For these patients, nebulizers are lifesavers: they convert liquid medication into fine aerosol droplets (1-5 microns) that can be inhaled directly into the lungs, delivering targeted treatment with minimal systemic side effects. However, the performance of a nebulizer hinges entirely on its assembly precision—even a 0.1mm misalignment in the atomizing chamber or a loose connection in the air tube can reduce medication delivery efficiency by 30% or more, endangering patient recovery. For decades, manual assembly of nebulizers struggled with inconsistency, low efficiency, and high defect rates. Today, Nebulizer Assembly Machine has revolutionized this landscape, becoming the unsung hero that ensures every nebulizer meets strict medical standards and delivers reliable treatment to respiratory patients.

The Evolution of Nebulizer Assembly Machines: From “Manual-Assisted” to “Intelligent Closed-Loop”

Nebulizer technology has evolved from bulky compressed-air models to portable mesh nebulizers, and its assembly equipment has followed three key development stages, each addressing critical industry pain points.

Semi-Automatic Assembly (1980s-2000s): Replacing Repetitive Manual Labor

The earliest nebulizer assembly machines focused on “reducing labor intensity” rather than full automation. For example, some machines could automatically press-fit the nebulizer cup (the container for liquid medication) with the base, but workers still needed to manually install the atomizing baffle, connect air tubes, and conduct leak tests. This phase had obvious limitations:

Efficiency bottlenecks: A single worker could only assist the machine in producing 200-300 nebulizers per hour, and the production line required 4-5 people to coordinate.

Quality risks: Manual installation of the atomizing baffle often led to misalignment, causing aerosol droplets to be too large (over 5 microns) and unable to reach the lungs. The defect rate remained around 2.5-3.5%, mainly due to human error.

Limited adaptability: These machines could only handle one type of nebulizer (e.g., jet nebulizers) and could not adapt to the emerging mesh nebulizers with more complex structures.

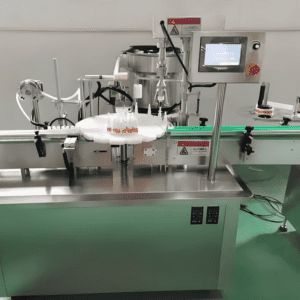

Fully Automatic Assembly Lines (2010s): Integrating Core Processes

With the rise of portable nebulizers and stricter medical device regulations, fully automatic assembly lines emerged, integrating component feeding, precision fitting, leak testing, functional verification, and laser marking into a continuous workflow. A mainstream fully automatic line could produce 800-1,200 nebulizers per hour, with the defect rate dropping to less than 0.5%. Key technical breakthroughs included:

Multi-axis servo control: Using 6-axis robots to install tiny components (e.g., mesh membranes for mesh nebulizers, which are only 0.1mm thick) with ±0.005mm accuracy, ensuring the mesh’s micro-holes (5-10 microns) are not blocked or deformed.

Air pressure leak testing: Inflating the nebulizer’s air chamber to 30kPa and monitoring pressure changes—if the pressure drops by more than 0.5kPa in 10 seconds, the product is rejected (this detects micro-leaks that manual inspection cannot identify).

Functional testing stations: Simulating actual use by pumping air into the nebulizer and measuring aerosol droplet size (using laser diffraction technology) and output rate—only products with 90% of droplets in the 1-5 micron range are qualified.

However, this generation of equipment still faced challenges: switching between different nebulizer models (e.g., pediatric portable nebulizers vs. adult home-use models) required replacing the entire feeding system and molds, taking 6-8 hours and making it difficult to meet small-batch customization needs.

Intelligent Flexible Lines (2020s-Present): Driven by AI and IoT

In recent years, under the impetus of “Medical Device Quality by Design (QbD)” and Industry 4.0, nebulizer assembly machines have entered the “intelligent flexible” era. These lines integrate AI vision inspection, real-time data monitoring, and modular quick-change systems, achieving a dual leap in efficiency and adaptability:

Rapid model switching: Modular feeding modules and parameterized control systems allow the line to switch between 4-6 common nebulizer models (from 5ml pediatric cups to 20ml adult cups) in 20-30 minutes—just by replacing the feeding tray and adjusting touchscreen parameters.

AI-powered defect detection: High-speed cameras capture 400-600 images per second, and AI algorithms (trained on millions of nebulizer images) automatically identify defects such as mesh membrane scratches, cup edge burrs, and incomplete air tube connections. The defect recognition rate reaches 99.97%, far exceeding the 95% rate of traditional machine vision.

IoT-based predictive maintenance: Sensors embedded in key components (e.g., robot grippers, leak-testing nozzles) monitor real-time data such as temperature, vibration, and pressure. When the wear of a gripper reaches 70% of its service life, the system sends a maintenance alert, reducing unplanned downtime by 45-55% compared to the “breakdown repair” model.

Core Technical Requirements: Why Nebulizer Assembly Demands “Extreme Precision”

Nebulizers are classified as Class II medical devices in most countries (e.g., FDA Class II in the U.S., CE Class IIa in the EU), and their assembly equipment must meet three non-negotiable technical standards to ensure patient safety and treatment efficacy.

Micron-Level Precision: The Key to Aerosol Quality

The core function of a nebulizer is to generate inhalable aerosol droplets, which depends entirely on the assembly precision of key components:

Mesh membrane alignment: For mesh nebulizers, the mesh membrane (with 10,000+ micro-holes per square centimeter) must be perfectly aligned with the vibration plate. A 0.003mm misalignment will cause 15% of micro-holes to be blocked, reducing aerosol output by 20%. Advanced assembly machines use laser positioning systems to adjust the membrane’s position in real time.

Air tube connection tightness: The air tube (which delivers compressed air to the nebulizer cup) must be connected with a torque of 0.8-1.2 N·m—too loose will cause air leakage (reducing aerosol pressure), too tight will crack the plastic connector. Torque sensors with 0.01 N·m precision ensure consistent connection force.

Liquid cup volume accuracy: The nebulizer cup’s internal volume (e.g., 5ml, 10ml) must have an error of less than ±0.05ml. If the cup is too small, it will overflow during medication filling; if too large, it will leave residual medication (wasting drugs and reducing efficacy). Assembly machines use 3D vision scanning to inspect cup volume after molding.

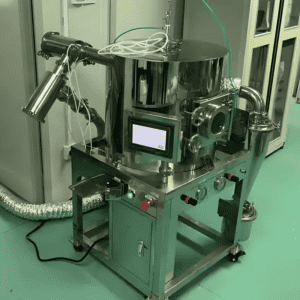

Sterility Compliance: Zero Tolerance for Contamination

Nebulizers come into direct contact with medication and respiratory tracts, so their assembly environment and equipment must meet GMP (Good Manufacturing Practice) Class 100 (ISO 5) cleanroom standards. High-end assembly lines integrate multiple sterility protection measures:

Closed-loop design: The entire assembly process is enclosed in a stainless steel chamber with HEPA filters, removing 99.97% of particles larger than 0.3 microns. Workers operate the machine through gloves attached to the chamber, avoiding direct contact with components.

Anti-static treatment: All equipment surfaces are coated with anti-static materials to prevent electrostatic adsorption of dust (which could contaminate the mesh membrane or medication cup).

CIP (Clean-in-Place) systems: For equipment used in disposable nebulizer assembly, automatic cleaning and disinfection cycles (using hydrogen peroxide vapor) are triggered between production batches, eliminating residual microorganisms.

Full-Lifecycle Traceability: Supporting Recall and Quality Improvement

In the event of a nebulizer defect (e.g., a batch of mesh nebulizers with blocked micro-holes), manufacturers need to quickly trace the source to minimize patient risk. Advanced assembly

machines achieve this through:

Unique identification marking: Laser engraving 2D codes on each nebulizer base, recording production date, batch number, equipment station, and operator information.

MES (Manufacturing Execution System) integration: Real-time synchronizing assembly data (e.g., torque parameters, leak-test results, aerosol droplet size) to the MES system. This allows manufacturers to trace every step of a nebulizer’s production—from raw material incoming inspection to finished product shipment—in 5 minutes or less.

Key Application Scenarios: Adapting to Diverse Respiratory Treatment Needs

Nebulizer assembly machines are not limited to standard models; they are also driving innovation in specialized nebulizers, meeting the unique needs of different patient groups and clinical scenarios.

Mesh Nebulizers: The Fastest-Growing Segment

Mesh nebulizers are compact, quiet, and energy-efficient (powered by batteries), making them ideal for home use and pediatric patients. Their assembly requires the most precise equipment:

Mesh membrane bonding: The ultra-thin mesh membrane (usually made of titanium or stainless steel) must be bonded to the plastic base using medical-grade adhesive, with a bonding thickness of 0.01-0.02mm. Too thick adhesive will block micro-holes; too thin will cause the membrane to fall off. Assembly machines use UV curing technology to control adhesive thickness and curing time.

Vibration system calibration: Mesh nebulizers rely on a piezoelectric ceramic vibration plate to generate aerosol. The assembly machine must calibrate the vibration frequency (100-200 kHz) and amplitude (5-10 microns) to ensure consistent droplet size—even a 5kHz frequency deviation can increase droplet size by 1 micron.

According to MarketsandMarkets, the global mesh nebulizer market will reach $1.8 billion by 2026, and the demand for mesh nebulizer assembly machines is growing at an annual rate of 18%.

Pediatric Nebulizers: Safety and Ergonomics First

Pediatric nebulizers (e.g., animal-shaped cups, colorful casings) require assembly equipment to balance precision with “child-friendly” design:

Soft material handling: The cup and mask of pediatric nebulizers are made of food-grade silicone (to avoid allergic reactions). Assembly machines use soft grippers (made of TPE) to avoid damaging the silicone during handling.

Leak-proof testing for small volumes: Pediatric nebulizers have smaller cups (2-5ml), so leak testing must be more sensitive. The equipment uses a “micro-pressure decay method”—inflating the cup to 15kPa and detecting pressure changes as small as 0.1kPa to ensure no medication leaks.

Hospital-Grade Nebulizers: High Durability and Stability

Hospital-grade nebulizers (used in ICUs for severe respiratory patients) need to withstand frequent use and disinfection. Their assembly requires reinforced equipment:

High-strength component assembly: The base and cup are made of PC (polycarbonate) with high impact resistance. The assembly machine uses reinforced clamping tools to press-fit components with a force of 15-20N (vs. 8-12N for home-use models), ensuring durability.

Disinfection resistance testing: After assembly, the nebulizer is subjected to 100 cycles of high-temperature (80°C) disinfection simulation. The equipment monitors whether components deform or loosen—only products that pass this test are qualified.

Future Trends: What’s Next for Nebulizer Assembly Machines?

As respiratory care technology advances (e.g., personalized medication, smart nebulizers) and global healthcare demands rise, nebulizer assembly machines will evolve in three key directions:

Integration of “Assembly-Testing-Packaging” Full Processes

Current production lines often require transferring nebulizers from assembly machines to testing stations and then to packaging lines, increasing the risk of contamination and efficiency loss. Future equipment will integrate automatic blister packaging, cartoning, and sterile bagging into a single closed loop. For example, a mesh nebulizer line could complete membrane bonding, functional testing, and sterile packaging in one continuous process, reducing production time by 35% and contamination risk by 60%.

Adaptation to Smart Nebulizers

Smart nebulizers (equipped with sensors to track medication usage, patient inhalation rate, and connect to mobile apps) are emerging. Assembly machines will need to handle “electromechanical integration” tasks:

Sensor installation: Precisely attaching micro-sensors (e.g., pressure sensors, flow sensors) to the nebulizer cup, ensuring no interference with aerosol generation.

Data communication testing: After assembly, the machine will test the sensor’s connection to the nebulizer’s circuit board and mobile apps—verifying that inhalation data is transmitted accurately to the app for doctors to monitor patient compliance.

Green and Low-Carbon Production

With global environmental regulations tightening (e.g., the EU’s Medical Device Regulation requiring recyclable materials), nebulizer assembly machines will focus on sustainability:

Material waste reduction: Optimizing feeding systems to reduce PC and silicone waste—current waste rates of 1.2% will be reduced to less than 0.5%.

Energy efficiency: Using servo motors with energy recovery functions and LED lighting in cleanrooms, cutting equipment energy consumption by 25-30% compared to current models.

Recyclable component compatibility: Designing assembly modules that can handle biodegradable plastics (e.g., PLA-based nebulizer cups), supporting the industry’s shift to eco-friendly materials.

Conclusion: Nebulizer Assembly Machines—The Silent Guardian of Respiratory Health

Behind every nebulizer that delivers life-saving medication to asthma patients, COPD sufferers, and children with respiratory infections, there is the precision support of nebulizer assembly machines. They have not only solved the inefficiency and quality risks of manual assembly but also laid the foundation for the innovation of respiratory medical devices—from portable mesh nebulizers that let patients live normal lives to smart nebulizers that enable personalized treatment. As global respiratory disease prevalence rises (exacerbated by factors like air pollution and aging populations), the demand for high-quality nebulizers will only grow. For medical device manufacturers, investing in advanced nebulizer assembly machines is no longer an option but a necessity—to ensure product safety, meet regulatory standards, and deliver reliable treatment to millions of patients. In the future, these machines will continue to evolve, becoming more intelligent, flexible, and sustainable, and safeguarding global respiratory health with even greater precision.