In the medical field, a precision error of a part can be directly related to surgical safety and patients’ lives. The core technology that supports this “millimeter-level requirement and micron-level control” is precisely precision CNC machining. With CNC machining centers as its core equipment, it converts digital instructions into accurate physical cutting, building a “precision moat” for medical part manufacturing.

Understanding Precision CNC Machining: More Than “Precision”—It’s “Controllability”

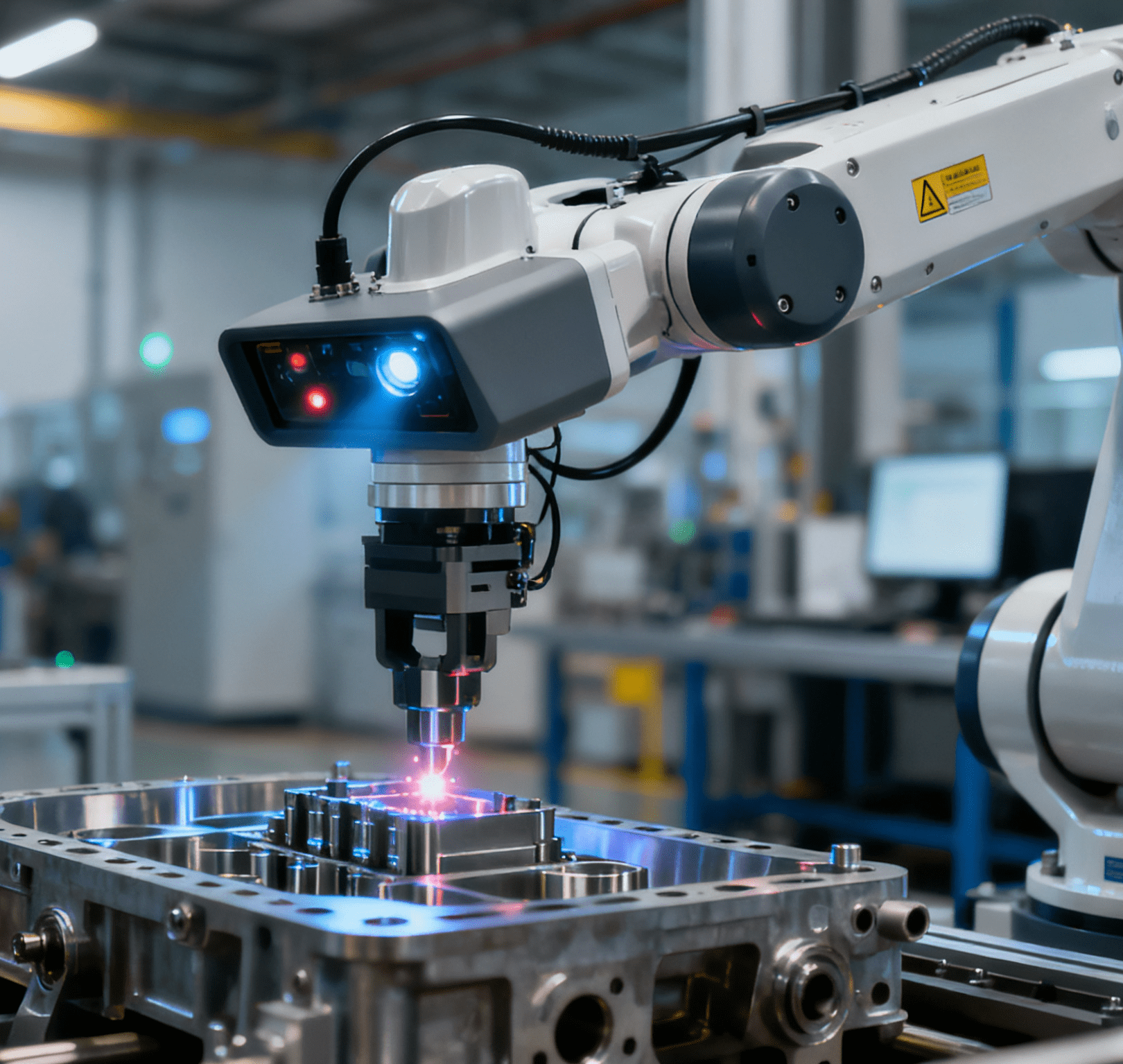

Precision CNC machining is not simply “machine-based processing,” but an integrated technology that combines digital programming, automated control, and materials science. Through pre-designed computer programs, it drives machine tools to complete operations such as cutting, drilling, and grinding along fixed trajectories, fundamentally addressing the pain points of traditional manual processing—”unstable precision and low efficiency.”

In the medical field, its core value is reflected in two aspects:

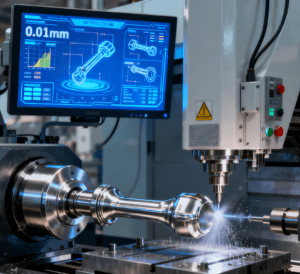

Controllable precision: It can stably achieve a machining error of 0.01mm, meeting the strict requirements for core parts such as artificial joints and surgical tools.

Strong consistency: The dimensional deviation of parts in the same batch can be controlled within the micron level, avoiding medical equipment failures caused by part variations.

CNC Machining Centers: The “Core Brain” of Precision Machining

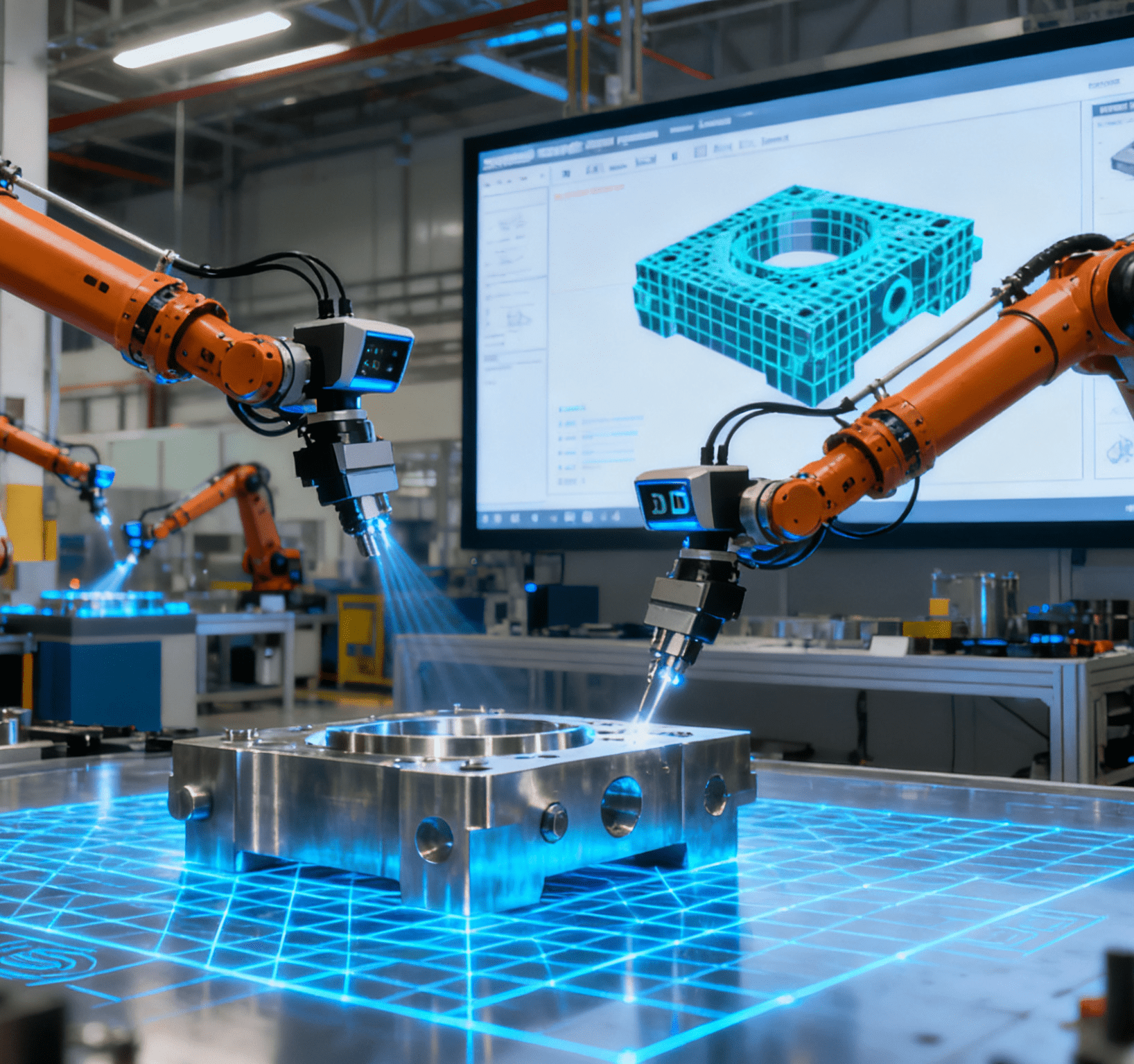

If precision CNC machining is the “cornerstone of high-precision production,” then CNC machining centers are the “core equipment” that enables this technology. They are not single machine tools, but composite automated equipment integrating milling, boring, and drilling functions—equivalent to a “multi-functional high-precision operation platform” for part manufacturing.

Compared with traditional machine tools, they have three major advantages in medical part processing:

Integrated multi-process processing: Medical parts often require complex structures (such as threads of implantable screws and occlusal teeth of surgical forceps). CNC machining centers can complete multiple processes in one go, avoiding precision loss caused by repeated clamping of parts.

Automation and intelligence: Through programming, 24/7 continuous production can be achieved. They are also equipped with real-time detection systems that automatically adjust if dimensional deviations occur, reducing the scrap rate of medical parts.

Wide material adaptability: They can accurately process medical-specific materials such as titanium alloys, medical stainless steel, and ceramics. These materials have high hardness and are prone to deformation, making them difficult to handle with traditional processing. However, CNC machining centers can achieve stable processing by adjusting cutting parameters.

Notably, the high-precision motion control and automated consistency guarantees of CNC machining centers are not limited to the medical field—they also underpin high-quality manufacturing in automotive precision assembly. For example, the Car Automatic Door Panel Buckle Assembly Machine, a key piece of equipment in automotive interior production, relies on CNC-derived positioning technology to achieve micron-level alignment when installing door panel buckles. This ensures that each buckle is assembled with uniform force and accurate position, preventing post-installation issues like abnormal noises or loosening due to assembly deviations—mirroring the strict consistency requirements that CNC machining applies to medical parts.

Medical Part Machining: The “Stringent Testing Ground” for Precision CNC Technology

The medical industry is one of the “highest-standard application scenarios” for precision CNC machining. From daily syringe accessories to human-implantable parts such as cochlear implants and spinal rod-screw systems, the manufacturing of every part relies on CNC technology.

Taking two types of key medical parts as examples, the irreplaceability of precision CNC machining can be clearly seen:

Surgical instruments (e.g., minimally invasive surgical knives): The blade needs to have an extremely thin edge and high sharpness. CNC machining centers can achieve 0.01mm-level precision control of the blade edge through high-speed milling, ensuring flat incisions during surgery and reducing tissue damage.

Implantable parts (e.g., artificial joint cups): They need to fit precisely with human bones, and the machining error of their spherical curvature must be controlled within 0.005mm. Through 3D modeling and real-time compensation technology, CNC machining centers can perfectly replicate the surface precision of design drawings, reducing the risk of post-operative loosening.

In addition, medical parts have extremely high requirements for “cleanliness” and “traceability.” During precision CNC machining, machine tools have strong sealing performance, which can reduce dust pollution. At the same time, the machining parameters (such as cutting speed and temperature) of each batch of parts are recorded and archived, enabling full-process quality traceability and complying with the strict standards of the medical industry.

The Significance Behind the Technology: Let “High Precision” Serve “Big Health”

The combination of precision CNC machining and medical part manufacturing is essentially the empowerment of “industrial technology” to “life and health.” It not only improves the reliability of medical equipment but also promotes the advancement of medical technology—for example, the popularization of minimally invasive surgery cannot do without the support of high-precision surgical instruments; the promotion of artificial organs relies on the accurate processing of biocompatible materials by CNC technology.

In the future, as medical technology moves toward “personalization” (such as customized artificial joints and 3D-printed medical parts), precision CNC machining will be further upgraded. Through more intelligent programming systems and higher processing efficiency, it will provide more flexible and accurate solutions for the medical industry.