In the field of modern high-end manufacturing, the demand for precision and efficiency in complex part machining is becoming increasingly stringent. Traditional 3-axis and 4-axis machine tools are limited by their degrees of motion freedom, presenting obvious bottlenecks in curved surface forming and multi-angle cutting. Equipped with a unique rotary axis design, 5-axis CNC machine tools enable five-directional linkage between cutting tools and workpieces. By dynamically adjusting machining angles, they integrate multiple processes of complex geometric components such as turbine blades and aerospace structural parts into a single clamping forming operation. This technological breakthrough not only reduces repeated positioning errors but also significantly improves curved surface finish and dimensional stability, providing disruptive solutions for the manufacturing of key components such as aerospace engines and precision molds. This paper systematically analyzes the technical advantages and industrial value of 5-axis machine tools from the perspectives of multi-axis coordinated machining principles, precision control mechanisms, and practical application scenarios.

Multi-Angle Machining Advantages of Multi-Axis Machine Tools

Compared with the planar motion mode of traditional 3-axis and 4-axis machine tools, 5-axis CNC machine tools achieve multi-dimensional linkage between cutting tools and workpieces in space through the dynamic coordination of rotary axes. This multi-angle coordinated machining feature allows the tool to always cut into the material surface at the optimal contact angle, which not only effectively eliminates machining blind spots but also significantly reduces cumulative errors caused by multiple clamping operations. When machining components with complex curved surfaces such as turbine blades and aero-engine casings, the machine tool can synchronously adjust tool posture and cutting paths, improving the forming efficiency of characteristic structures such as deep grooves and special-shaped holes by more than 40%. Meanwhile, there is no need to interrupt the equipment for workpiece position adjustment during the continuous machining process, which not only ensures the geometric continuity between machined surfaces but also shortens the auxiliary operation time by approximately 30%. Notably, when matched with the Robotic Small Product Tray Loading System, 5-axis CNC machine tools can realize automatic loading of small-sized complex workpieces (such as precision mold inserts and micro aerospace components) and automatic unloading of finished products into trays; this integrated automation solution further reduces manual intervention, avoids positioning deviations caused by manual loading and unloading, and ensures the continuity of the entire machining flow, making the auxiliary operation efficiency improved by an additional 15% on the original basis.

How 5-Axis Machining Enables Complex Part Forming

5-axis CNC machine tools break through the spatial constraints of traditional machining equipment through multi-angle linkage machining technology. The core lies in the ability of the spindle and workpiece table to perform dynamic coordinated movements along five axes, allowing the cutting tool to contact the machining surface at any angle. This degree of freedom enables parts with complex curved surfaces such as turbine blades and aero-engine casings to complete multi-surface machining without multiple clamping, avoiding cumulative errors caused by repeated positioning. During the machining process, the built-in intelligent algorithm of the equipment real-time calculates tool paths and cutting parameters, implementing precise cutting of features such as deep cavities and special-shaped contours to ensure the continuity of curved surface transitions. Taking titanium alloy structural parts in the aerospace field as an example, the 5-axis system can synchronously adjust tool inclination and rotation speed, completing the integral forming of thin-walled parts while maintaining a precision level of 0.005 mm, which significantly improves the machining integrity of complex geometric components.

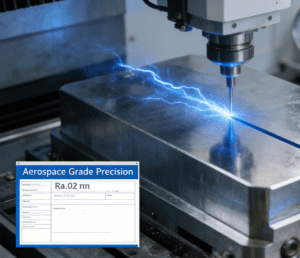

Precision Breakthroughs in Aerospace Manufacturing

In the machining of key components such as aero-engine blades and spacecraft structural parts, traditional 3-axis/4-axis machine tools are often forced to adopt multi-clamping processes due to angle limitations, resulting in cumulative part positioning errors of more than 0.05 mm. 5-axis CNC machine tools achieve complete cutting of complex curved surfaces such as turbine disk dovetail grooves and special-shaped skins by synchronously controlling the 5 degrees of freedom of the spindle and worktable, improving the overall machining precision to the ±0.005 mm level. For example, after adopting 5-axis linkage technology for a certain type of aero-engine high-pressure turbine blade, the blade profile tolerance error is reduced by 62%, and the surface roughness Ra value is stably controlled within 0.4 μm, which significantly improves the aerodynamic performance and fatigue life of the component. This precision breakthrough not only solves the problem of deformation control of thin-walled parts but also ensures that the overall assembly clearance meets the design requirements, serving as a core technical support for improving the reliability of aerospace equipment.

What Makes 5-Axis Machining Superior to 3-Axis and 4-Axis?

Compared with traditional 3-axis and 4-axis machine tools, the core advantage of 5-axis CNC machine tools lies in the breakthrough improvement of motion degrees of freedom. 3-axis machine tools can only realize basic displacement along the X/Y/Z linear axes, while 4-axis machine tools achieve single-angle inclined machining by adding a rotary axis (e.g., A-axis), but complex curved surfaces still rely on multiple clamping adjustments. The 5-axis system, through the synchronous linkage of dual rotary axes (e.g., A+C axes or B+C axes), enables the tool to cut into the workpiece surface from any angle, completely eliminating machining blind spots. This multi-dimensional coordinated movement not only reduces the machining processes of complex parts by more than 60% but also stabilizes the overall machining precision within 0.005 mm by reducing cumulative errors caused by repeated positioning. Taking the machining of turbine blades in the aerospace field as an example, a 5-axis machine tool can complete the precision forming of composite structures such as twisted blade profiles and cooling channels in a single clamping, whereas a 4-axis system requires 5-6 fixture adjustments, leading to a significant increase in the risk of surface tool marks and dimensional deviations. In addition, the dynamic compensation system of 5-axis machine tools can real-time correct the tool posture, improving the cutting stability of special structures such as deep cavities and undercuts by 40%—a technological leap that is difficult to achieve with 3-axis and 4-axis equipment.

The technological breakthrough of 5-axis CNC machine tools is reflected not only in the expansion of machining dimensions but also in the reconstruction of the logical chain of complex curved surface machining through a multi-angle linkage mechanism. From titanium alloy structural parts in the aerospace field to micron-level curved surfaces of precision molds, the equipment integrates dispersed machining processes in traditional craftsmanship into continuous operations by reducing clamping times and tool interference risks. This integrated machining mode increases material removal rate by 20%-35% while stabilizing dimensional tolerances within ±0.5 mm. Compared with the planar limitations of 3-axis machine tools and the axial constraints of 4-axis machine tools, the spatial trajectory planning capability of 5-axis systems truly achieves seamless mapping between design models and physical forming, which is the core driving force for the continuous iteration of process equipment in the high-end manufacturing field.