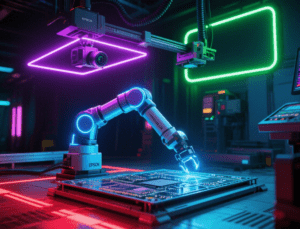

4-Axis Robotic Frame Pick-up System: Revolutionizing High-Speed Material Handling in Smart Manufacturing

In the fast-paced landscape of modern manufacturing, efficiently handling large and complex frames—such as PCB panels, automotive body frames, or display modules—poses significant challenges for traditional material handling systems. Manual or semi-automated solutions suffer from slow cycle times (20–40 seconds per frame), inconsistent positioning (±1mm errors), and limited adaptability to diverse frame sizes and weights. The 4-Axis Robotic Frame Pick-up System emerges as a transformative solution, integrating high-speed SCARA robotics, intelligent vision guidance, and adaptive gripping technologies to streamline frame handling in high-volume production environments. This article explores its technical architecture, industrial applications, and role in driving next-generation manufacturing efficiency.

- Core Technical Architecture: Precision Meets Velocity

The system synergizes 4-axis SCARA robotics, AI-powered vision systems, and adaptive frame grippers to achieve rapid, accurate frame pick-up with unmatched repeatability. Its architecture comprises four interdependent subsystems:

- High-Speed 4-Axis Robot Manipulation

SCARA robots (e.g., Epson LS10, Yamaha YK-XG series) form the core, offering:

- Planar Motion Dominance: Achieving pick-up speeds of 60–80 frames per hour (55″–75″ sizes) with ±0.05mm repeatability, 2–3 times faster than traditional systems

- Payload Optimization: Carbon fiber arms handling 10–50kg frames (including end-effectors), balancing speed with stability for large-format components

- Extended Reach: Horizontal reach up to 1,200mm and vertical stroke up to 400mm, ideal for accessing frames in stacked pallets or conveyor systems

- Vision-Guided Frame Localization & Alignment

A dual-camera vision setup ensures millimeter-level accuracy:

- Overhead 3D Camera: 16MP+ resolution with structured light scanning maps frame edges and mounting holes, correcting for ±15mm lateral shifts using point cloud processing

- Laser Line Profiler: Scans frame warpage (up to 0.3mm/m) and surface topography, generating adaptive pick-up trajectories to prevent deformation during handling

- Dynamic Tracking: Synchronizes with moving conveyors (speed up to 2m/s) using predictive control, enabling continuous frame picking without line stoppage

- Adaptive Frame Gripping Solutions

End-effectors combine precision mechanics with smart sensing:

- Modular Vacuum Gripping: Customizable suction cup arrays (4–12 cups) for non-porous frames (glass, metal, plastic), with pressure sensors monitoring grip integrity (deviation <0.1kPa)

- Hybrid Mechanical Grippers: Clamping mechanisms for perforated or irregular frames, with force-torque sensors adjusting pressure (10–50N range) to prevent damage

- Quick-Change Tooling: Swaps between gripper modules in <15 seconds using pneumatic quick-disconnects, supporting rapid adaptation to new frame designs

- Intelligent Control Software

The system’s digital backbone enables seamless automation:

- Recipe Management: Stores 300+ frame specifications (size, weight, grip points) with one-click activation, reducing changeover time to <3 minutes

- Path Optimization AI: Machine learning algorithms analyze historical pick-up data to generate optimal trajectories, minimizing robot travel distance by 30%

- IIoT Integration: Connects to MES systems via OPC UA, tracking OEE, cycle time, and gripper wear for predictive maintenance scheduling

- Industrial Applications: Streamlining Frame Handling

- Display Panel Manufacturing

In TV and monitor production, the system excels at:

- Large LCD/OLED Panel Handling: Picking 55″–100″ display frames with anti-glare coatings using vacuum grippers, maintaining surface flatness (warpage <0.1mm) critical for pixel alignment

- Curved Panel Pick-up: Adapting to 3D curved frames (curvature radius ≥500mm) using 3D vision data to ensure perpendicular grip, preventing panel stress

Case Study: A leading Chinese display manufacturer reduced frame handling defects by 85% and increased production capacity by 40% after deploying 50 systems, achieving 24/7 operation with 99.9% uptime.

- Automotive Body-in-White Handling

For vehicle chassis and frame assembly:

- Car Body Frame Pick-up: Handling steel/aluminum frames (20–150kg) with magnetic grippers, aligning with welding fixtures using laser guidance (±0.2mm accuracy)

- Multi-Frame Kitting: Sequentially picking door frames, roof rails, and chassis components into AGV transport systems, supporting just-in-time production

- Weld Spatter Resistance: High-temperature gripper coatings (up to 300°C) withstand welding environment hazards, extending tool life by 50%

- Electronics Manufacturing & PCB Handling

In semiconductor and PCB assembly:

- Large PCB Panel Pick-up: Handling 600mm×450mm PCB frames with anti-static vacuum cups, ensuring no ESD damage to surface-mounted components

- Modular Electronics Frame Loading: Picking pre-assembled electronic subframes (e.g., server chassis) into testing fixtures with ±0.1mm vertical alignment

- Cleanroom Compliance: ISO 5-rated gripper materials and ionizing blowers for semiconductor manufacturing, meeting strict contamination control standards

III. Competitive Advantages Over Traditional Systems

| Performance Metric | Traditional Frame Handling | 4-Axis Robotic System |

| Pick-up Speed (frames/hour) | 20–30 | 60–80 |

| Positioning Accuracy | ±1mm | ±0.05mm (X/Y), ±0.1mm (Z) |

| Changeover Time (new frame) | 20–40 min | <3 min (recipe-based) |

| Defect Rate (handling) | 0.8–1.5% | <0.03% |

| Labor Requirement (per line) | 3–4 operators | 1 supervisor (remote) |

| Frame Variety Support | Limited (5–8 types) | 300+ types (modular tooling) |

- Technological Frontiers & Future Innovations

- AI-Driven Self-Optimization

Machine learning models analyze historical data to:

- Predict optimal grip points for new frame designs, reducing trial-and-error setup by 70%

- Adapt pick-up force in real-time based on frame material (steel, aluminum, composite)

- Forecast gripper wear (e.g., vacuum cup degradation) with 92% accuracy, triggering proactive maintenance alerts

- 3D Vision & Dynamic Environment Adaptation

Upgrades to LiDAR and ToF sensors enable:

- Handling frames with complex 3D features (e.g., automotive chassis with integrated brackets)

- Real-time collision avoidance in dynamic workspaces with multiple robots and AGVs

- Collaborative Robotics Integration

Dual-arm cobots (e.g., Universal Robots UR10e) with force-torque sensors are being developed for:

- Shared workspaces where robots handle heavy frames while humans perform quality checks

- Flexible cells supporting small-batch, high-mix production with quick reconfiguration

- Sustainable Design Innovations

Key developments include:

- Regenerative drives recovering 30% of braking energy during Z-axis motion

- Low-power standby modes reducing energy consumption by 40% in idle periods

- Recyclable composite materials for robot arms and grippers, aligning with global ESG manufacturing goals

Conclusion

The 4-Axis Robotic Frame Pick-up System represents a paradigm shift in automated material handling, addressing the critical needs for speed, precision, and flexibility in modern manufacturing. By eliminating manual inefficiencies, reducing changeover times, and enabling data-driven quality control, it becomes a strategic asset in smart factory ecosystems. As Industry 4.0 progresses, these systems will evolve—integrating AI, 3D vision, and collaborative capabilities—to meet the demands of mass customization, where every frame’s journey from production to assembly is optimized for efficiency and reliability.

Keywords: 4-Axis Robotic Frame Pick-up System, SCARA Robot Frame Handling, Vision-Guided Frame Picking, High-Speed Material Handling System, AI-Powered Frame Gripping, Smart Factory Frame Automation, Modular Tooling for Frame Systems, Precision Frame Positioning, Industrial Robotics Vision Technology, IIoT-Enabled Frame Handling

#4-Axis SCARA Robot Frame Handling System #Automotive Body Frame Handling System #High-Speed Frame Loader for PCB Assembly